What is PN10 pvc ball valve?

A PN10 PVC ball valve uses polyvinyl chloride material to handle liquid flow in pipelines. The PN10 rating shows it operates safely at pressures up to 10 bar (145 psi). Many water supply, irrigation, and industrial systems depend on this type of pvc ball valve for its reliability and simple operation.

Key Takeaways

- PN10 PVC ball valves operate safely at pressures up to 10 bar (145 psi), making them reliable for various fluid systems.

- These valves are lightweight, corrosion-resistant, and cost-effective, offering advantages over metal alternatives.

- Proper installation and regular inspections are crucial for maintaining the performance and longevity of PN10 PVC ball valves.

Understanding PN10 pvc ball valve

What Does PN10 Mean?

PN10 refers to the pressure nominal rating of a pvc ball valve. This rating indicates that the valve can safely operate at a maximum pressure of 10 bar, which equals 145 psi. International standards, such as ANSI 150 lb flanged valves, confirm that all sizes rated PN10 can handle 150 psi at 70°F in non-shock conditions. The PN10 rating helps users select the right valve for their system, ensuring reliable performance under specified pressure limits.

Tip: Always check the pressure rating before installation to prevent system failures.

The following table compares PN10 with another common pressure rating:

| Pressure Rating | Maximum Working Pressure at 20°C |

|---|---|

| PN10 | 10 bar |

| PN16 | 16 bar |

Structure and Function of a PVC Ball Valve

A pvc ball valve consists of several key components: a body made from polyvinyl chloride, a spherical ball with a hole through the center, and a handle for manual operation. When the handle turns, the ball rotates to either allow or block fluid flow. The design provides quick shut-off and precise control, making it suitable for many applications.

Manufacturers specify that the maximum operating temperature for a PN10 pvc ball valve ranges from 5 ℃ to 95 ℃. This wide temperature range allows the valve to function in various environments, from cold water systems to warmer industrial processes.

PN10 pvc ball valves undergo rigorous high-pressure testing. These valves feature flanged ends for secure installation and demonstrate durability and reliable performance in high-pressure conditions. The UPVC plastic ball valve, with its PN10 rating, handles pressures up to 150 PSI, meeting the demands of modern piping systems.

The table below highlights certifications required for use in potable water systems:

| Model Number | Material | Description | Certificate |

|---|---|---|---|

| UCB01 | PVC | COMPACT BALL VALVE | NSF/UPC |

Key Features and Benefits

PN10 pvc ball valves offer several advantages over metal alternatives, especially in corrosive environments. The table below outlines these benefits:

| Advantage | PVC Ball Valves | Metal Ball Valves |

|---|---|---|

| Corrosion Resistance | Excellent, ideal for corrosive environments | Poor, prone to rust and corrosion |

| Weight | Lightweight, easy to handle | Heavy, requires more support |

| Cost | Generally more affordable | More expensive |

| Durability | Durable with proper maintenance | Can corrode over time |

| Versatility | Suitable for various applications | Limited to specific uses |

Recent technological advancements have improved the design and performance of PN10 pvc ball valves. The following table summarizes these features:

| Feature | Description |

|---|---|

| Compact Design | Allows fitting in smaller spaces compared to traditional ball valves. |

| Ease of Operation | Quarter-turn handles that are easy to operate and can be partially opened. |

| Corrosion Resistance | Made from corrosion-resistant PVC material. |

| Low Lead Content | Wetted surfaces contain less than 0.25% lead content. |

| Large Ports | Designed for greater flow with minimal pressure drop/turbulence. |

| Versatile Use | Suitable for various media including water, air, and corrosive chemicals. |

| Cost-Effective | PVC is a cost-effective material compared to other plastics. |

| Easy Maintenance | True union valves allow for easy removal for inspection and cleaning. |

Environmental impact also plays a significant role in the selection of pvc ball valves. The table below shows how PVC compares to metal alternatives:

| Aspect | Description |

|---|---|

| Recyclability | PVC material can be recycled, reducing environmental burden. |

| Minimal environmental footprints | Manufacturing PVC has a lower environmental footprint compared to metal alternatives. |

| Sustainability goals | PVC ball valves align with sustainability goals due to their long lifespan and recyclability. |

Additional benefits include:

- Chemical resistance

- Cost-effectiveness

- Low maintenance requirements

PN10 pvc ball valves combine durability, affordability, and environmental responsibility, making them a preferred choice for many fluid control systems.

Applications and Selection of pvc ball valve

Common Uses in Residential, Commercial, and Industrial Settings

PN10 pvc ball valves serve a wide range of applications due to their durability and resistance to corrosion. In residential plumbing, these valves control water supply, manage irrigation systems, and regulate flow in swimming pools and aquariums. Commercial and industrial facilities rely on them for waste treatment and process water management. The table below highlights typical uses in residential systems:

| Application Type | Description |

|---|---|

| Water Supply | Used for supplying water in residential systems. |

| Irrigation | Commonly used in agricultural irrigation systems. |

| Swimming Pools | Utilized in plumbing for pools and water parks. |

| Aquariums | Applied in aquarium plumbing setups. |

| Waste Treatment | Used in systems for treating water and waste. |

How to Select the Right PN10 PVC Ball Valve

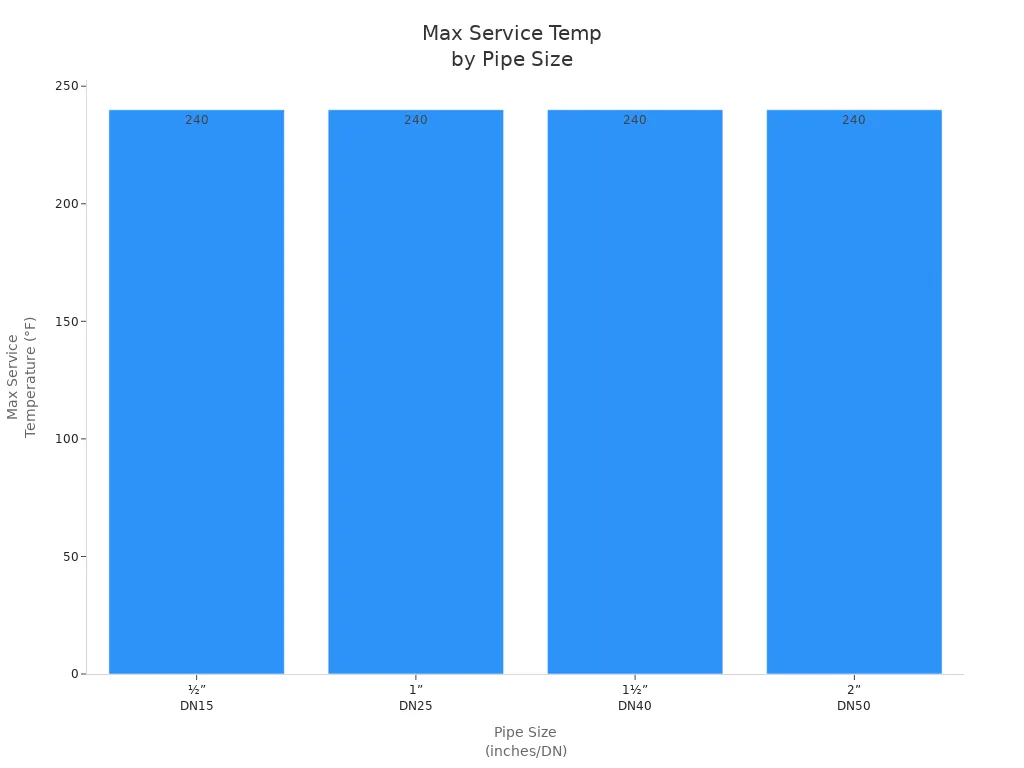

Selecting the correct pvc ball valve depends on several factors, including pipe diameter, pressure rating, and temperature requirements. Pipe size directly influences the valve’s pressure capacity and service temperature. The following table shows common sizes and their specifications:

| Size (inches) | Size (DN) | Pressure Rating (psi) | Maximum Service Temperature (°F) |

|---|---|---|---|

| ½” | DN15 | 150 | 240 |

| 1” | DN25 | 150 | 240 |

| 1½” | DN40 | 150 | 240 |

| 2” | DN50 | 150 | 240 |

Engineers should also consider chemical compatibility and installation environment. Proper selection ensures reliable operation and extends the service life of the valve.

Installation Tips and Considerations

Proper installation and maintenance maximize the performance of a PN10 pvc ball valve. Technicians should follow these best practices:

- Conduct regular inspections for stress, discoloration, or joint movement.

- Verify that pipe supports remain secure and correctly spaced.

- Monitor system pressure and flow rates to detect issues early.

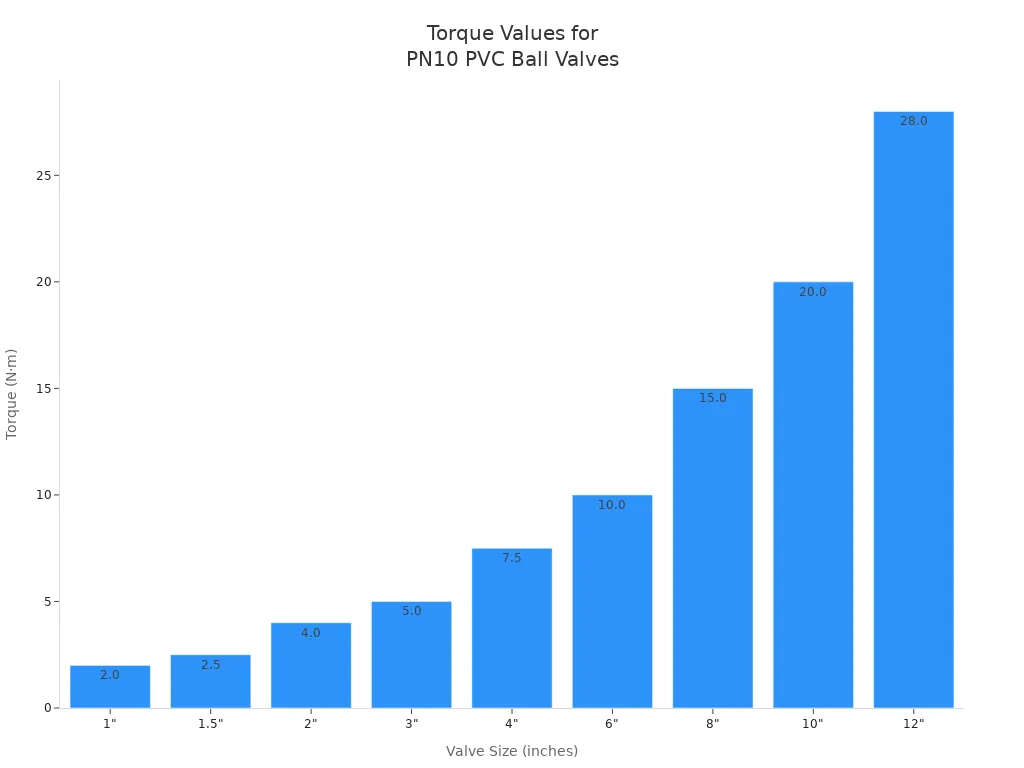

Torque values play a crucial role during installation. The chart below provides recommended torque values for various valve sizes:

Tip: Always use the manufacturer’s recommended torque to prevent damage and ensure a leak-free seal.

PN10 PVC ball valves deliver reliable flow control with strong pressure ratings and durable construction. Proper installation and regular maintenance support long-term performance:

- Avoid stress during installation to prevent early failure.

- Clean valves regularly to maintain optimal function.

| Product Name | Warranty Duration | Certification |

|---|---|---|

| ERA True Union Ball Valve | Up to 50 years | NSF Certified |

These valves suit many fluid systems due to their corrosion resistance and versatility.

FAQ

What does the PN10 rating mean for a PVC ball valve?

PN10 indicates the valve can safely operate at pressures up to 10 bar (145 psi). This rating ensures reliable performance in most water and fluid systems.

Can a PN10 PVC ball valve handle chemicals?

Manufacturers design PN10 PVC ball valves to resist many chemicals. Always check the chemical compatibility chart before installation for specific fluids.

Tip: Consult the manufacturer’s datasheet for chemical resistance information.

How often should technicians inspect PN10 PVC ball valves?

Technicians should inspect valves every six months. Regular checks help maintain performance and prevent leaks or failures in the system.

| Inspection Frequency | Recommended Action |

|---|---|

| Every 6 months | Visual inspection |

| Annually | Full system check |