Upvc pipe fittings

UPVC pipe fittings connect and secure pipes in plumbing and fluid systems. Their rigid structure ensures leak-free performance. Many industries value a quality upvc fitting for its strength and chemical resistance. These fittings help maintain system reliability and support efficient fluid transport in demanding environments.

UPVC pipe fittings connect and secure pipes in plumbing and fluid systems. Their rigid structure ensures leak-free performance. Many industries value a quality upvc fitting for its strength and chemical resistance. These fittings help maintain system reliability and support efficient fluid transport in demanding environments.

Key Takeaways

- UPVC pipe fittings offer strong durability, chemical resistance, and long service life, making them ideal for residential, commercial, and industrial plumbing systems.

- A wide variety of UPVC fittings like couplings, elbows, tees, and valves allow flexible, leak-proof, and easy-to-maintain piping designs for many applications.

- Proper installation using simple tools and following steps like cutting squarely, cleaning, priming, and curing ensures reliable, leak-free connections that last for decades.

Advantages of UPVC Fitting

Durability and Longevity

UPVC fittings deliver outstanding durability in both residential and industrial settings. They resist chemical aging and maintain their physical properties even when exposed to household or industrial waste. These fittings show low material fatigue, absorbing operational stresses without cracking. Minimal maintenance is required, as the surfaces resist internal damage and external wear. Field performance data confirms that UPVC drainage systems function reliably for decades. The fittings remain stable under heavy soil loads and ground pressure, resisting crushing and deformation. Their non-corrosive structure prevents rust and decay, while UV resistance supports long-term outdoor use.

- UPVC fittings maintain consistent performance over time, with no soft spots or weakened joints.

- Reliable sealing is achieved through strong solvent welds and rubber gaskets.

- Smooth internal surfaces resist buildup and scaling, ensuring steady flow.

Safety and Non-Toxicity

UPVC pipes and fittings are made from non-toxic, eco-friendly virgin compounds. They do not contain plasticizers or heavy metals, ensuring zero leaching into drinking water. These products comply with national and international potable water standards. Manufacturers use high-grade raw materials and conduct extensive testing for safety. UPVC fittings are widely used in sensitive environments such as schools and hospitals. The smooth inner surface prevents scale buildup, contributing to water purity.

- 100% lead-free and free from heavy metals.

- Non-reactive and resistant to high temperatures up to 60°C.

- Manufactured to meet ASTM D2467 and ISO 1452 standards.

Corrosion and Chemical Resistance

Laboratory tests show that UPVC fittings withstand immersion in acids, alkalis, and saltwater without significant changes in their properties. Accelerated aging tests confirm their resistance to chemical corrosion and degradation. Even after long-term exposure to disinfectant solutions, UPVC maintains its structural integrity. This chemical resistance makes the upvc fitting ideal for harsh environments where metal alternatives would corrode.

Note: The fully plastic structure prevents rust and decay from soil or waste contact.

Ease of Installation

UPVC pipe accessories are lightweight and easy to handle, making installation straightforward. Solvent welding is a simple process that requires minimal tools, such as a pipe cutter, deburring tool, and solvent cement. The process involves cleaning, dry-fitting, applying cement, and joining the parts. Installers can complete the process quickly, even in locations with limited access. Solvent welded joints form strong, leak-proof bonds, ensuring reliability.

- Suitable for field installations.

- Minimal tools required.

- Quick curing time before pressurizing the system.

Cost-Effectiveness

UPVC fittings offer long-term savings due to their durability and low maintenance needs. Market reports highlight the growing demand for UPVC in construction, driven by its cost-effectiveness and performance. The material’s long lifespan, exceeding 30 years, reduces the frequency of replacements. UPVC supports multiple recycling methods, saving energy and raw materials. Manufacturing produces minimal waste, with byproducts repurposed in other industries.

- uPVC recycling saves approximately 2,000 kg of CO₂ emissions and 1,800 kWh of energy per ton.

- Energy savings can recover the initial investment in premium profiles within 3 to 7 years.

- The global UPVC market continues to grow, reflecting its value in building and infrastructure.

Main Types of UPVC Fitting

UPVC pipe systems rely on a diverse range of fittings to create robust, adaptable, and efficient networks. Each fitting type serves a unique function, ensuring that the system meets specific design and operational requirements. Industry reports classify these fittings by their roles in joining, redirecting, branching, or sealing pipes, and highlight their performance in terms of durability, pressure handling, and ease of maintenance.

Couplings

Couplings join two sections of UPVC pipe, forming a continuous, leak-proof channel. Manufacturers offer several types, including slip, repair, and expansion couplings. Precision molding with tight dimensional tolerances (±0.1mm) ensures that each coupling delivers a secure fit and long-term stability. Quality control standards such as ASTM D1785 and ISO 9001 govern the production process, resulting in consistent performance. Salt spray testing over 5,000 hours confirms the corrosion resistance of these fittings. Field measurements and certifications demonstrate that couplings maintain sealing performance for over 30 years in typical applications.

Tip: Use couplings for quick repairs or system extensions, as they allow for easy alignment and minimal disruption.

Elbows

Elbows change the direction of flow within a UPVC piping system. The most common angles are 45° and 90°, allowing for flexible routing around obstacles or within confined spaces. Elbows help maintain optimal flow rates by minimizing turbulence at bends. Industry standards require these fittings to withstand internal pressure and mechanical stress without deformation. Elbows play a critical role in both residential and industrial installations, supporting efficient system layouts.

Tees

Tees enable branching within a pipeline, creating multiple flow paths from a single source. This fitting features a T-shaped design, allowing for the connection of three pipes. Tees are essential in distribution networks, such as water supply and irrigation systems, where fluid must reach several destinations. Manufacturers design tees to handle equal or varying pressures across all branches, ensuring balanced distribution.

Unions

Unions provide a convenient way to disconnect and reconnect sections of UPVC piping without cutting or removing fittings. This feature simplifies maintenance, repairs, and system modifications. Unions consist of three parts: two end pieces and a central nut that secures the connection. The design allows for repeated assembly and disassembly while maintaining a reliable seal. Unions are especially valuable in systems that require frequent inspection or cleaning.

Adapters

Adapters connect pipes of different diameters or transition between UPVC and other materials. These fittings support system flexibility and compatibility with various piping standards. Manufacturers test adapters for dimensional accuracy, tensile strength, and pressure resistance. The following table summarizes key certification standards and factory testing procedures for adapter fittings:

| Certification Standards | Description |

|---|---|

| BS EN ISO 1452-2, BS EN ISO 1452-3 | European standards for PVC-U pressure pipes and fittings |

| ASTM D 2466, ASTM D 2467 | American standards for PVC-U pipe fittings (SCH40 and SCH80) |

| AS/NZS1477 | Australian/New Zealand standard for PVC-U pipes and fittings |

| BS4346 | British standard for PVC-U pressure pipe and fittings |

| JIS Standards | Japanese Industrial Standards for PVC-U pressure fittings |

| EN1329, EN1401, ISO3633 | Standards for drainage systems |

| ASTM D2665, AS/NZS1260 | Standards for DWV (Drain, Waste, Vent) systems |

| Factory Testing Procedures | Purpose/Verification |

|---|---|

| Dimensional checks | Ensures proper network adaptability |

| Visual inspection | Detects surface defects |

| Tensile strength test | Verifies structural integrity |

| Pressure testing (water/air) | Confirms resistance to operational pressures |

| Impact resistance test | Assesses durability against shocks |

| Chemical resistance test | Ensures resistance to degradation |

| UV resistance test | Validates outdoor suitability |

| Hydrostatic pressure test | Tests resistance to internal water pressure |

| Flammability test | Checks fire safety compliance |

| Heat deflection temperature test | Determines maximum operating temperature |

| Flow rate testing | Ensures minimal flow restriction |

Adapters play a vital role in expanding or upgrading existing networks, making them a key upvc fitting for system adaptability.

Reducers

Reducers connect pipes of different diameters, allowing for smooth transitions in flow capacity. Engineers use stress analysis and optimization design to improve the structural integrity of reducers. By assessing stress distribution, they can select materials and reinforce designs to handle applied loads efficiently. This process reduces the risk of failure and extends the service life of the fitting. Reducers help maintain system pressure and prevent turbulence at diameter changes.

End Caps

End caps seal the open ends of UPVC pipes, preventing fluid escape and contamination. These fittings are essential during system testing, maintenance, or when future expansion is anticipated. End caps must withstand internal pressure and resist impact or environmental exposure. Their simple design allows for quick installation and removal as needed.

Valves

Valves regulate fluid flow within UPVC piping systems. Common types include ball and gate valves, each offering precise control over pressure and volume. Industry standards specify pressure ratings up to 6000 psi and temperature ranges from -65°F to 450°F. Manufacturers use high-quality PVC for valve bodies, while seals and O-rings are made from EPDM or PTFE to ensure chemical resistance and leak prevention. Advanced manufacturing and testing guarantee stable product quality and long service life, often exceeding 25 years. Valves protect systems from water hammer effects and maintain consistent pressure, making them indispensable in irrigation, industrial, and municipal applications.

Note: Plastic valves offer advantages over metal alternatives, such as lighter weight, superior corrosion resistance, and longer operational lifespan.

Flanges

Flanges provide a secure method for joining pipes and equipment, facilitating assembly, disassembly, and maintenance. These fittings use bolts and gaskets to create a tight seal, supporting high-pressure and high-temperature applications. Flanges are common in industrial settings where frequent access to the pipeline is necessary. Their robust construction ensures reliable performance under demanding conditions.

Crosses

Cross fittings connect four pipes at right angles, forming a plus-shaped intersection. These fittings are used in complex plumbing layouts where multiple branches converge. Crosses must distribute pressure evenly across all outlets to prevent leaks or structural failure. They are often found in large-scale water distribution or fire suppression systems.

Wyes

Wyes divert flow into two separate pipelines at a gentle angle, typically 45°. This design reduces turbulence and supports efficient drainage. Wyes are commonly used in sewer and stormwater systems to direct waste or runoff into secondary lines. Their smooth internal surfaces minimize blockages and maintain steady flow rates.

Summary:

The wide variety of upvc fitting types allows engineers and installers to design systems that meet specific operational, safety, and maintenance requirements. Industry reports emphasize the importance of selecting the right fitting for each application, considering factors such as material compatibility, pressure ratings, and adherence to standards.

Applications of UPVC Fitting

Residential Plumbing

UPVC fittings play a vital role in modern residential plumbing systems. Homeowners and builders prefer these fittings for their corrosion resistance, high pressure tolerance, and long service life. Plastic pipes and fittings, including UPVC and CPVC, outperform metal alternatives in durability and environmental impact. Case studies show that plastic piping systems reduce lifecycle costs by up to 63% and lower CO₂ emissions by approximately 42%. Lightweight construction and easy installation help address skilled labor shortages in the plumbing industry. Market research highlights growing demand for UPVC pipes, driven by investments in water supply and infrastructure. These factors make UPVC fittings a reliable choice for both hot and cold water applications in homes.

- Corrosion resistance ensures clean water delivery.

- Long lifespan reduces maintenance and replacement needs.

- Lightweight design simplifies installation.

Commercial Plumbing

Commercial buildings require plumbing systems that handle high usage and strict performance standards. UPVC fittings meet these demands through advanced designs and robust materials. True Union PVC fittings allow easy installation and maintenance, reducing downtime and operational costs. Noise-reducing UPVC fittings, featuring thicker walls and specialized mounting systems, help create quieter environments in offices and hotels. These products comply with international acoustic standards, ensuring comfort for building occupants. The wide range of available sizes and accessories supports diverse commercial applications.

- Corrosion and chemical resistance extend system life.

- Smooth inner surfaces reduce clogs and maintenance.

- Specialized couplings and clamps minimize noise and vibration.

Industrial Systems

Industrial facilities depend on reliable piping for water treatment, chemical processing, and fluid transport. UPVC valves and fittings offer corrosion resistance and chemical compatibility, making them suitable for harsh environments. Their cost-effectiveness and low maintenance requirements lead to long-term savings. The global UPVC injector market continues to grow, reflecting increased adoption in industrial applications. Manufacturers focus on quality and innovation, ensuring that each upvc fitting meets strict performance benchmarks.

- Streamlined design improves energy efficiency.

- Easy installation supports operational efficiency.

- High durability withstands demanding industrial conditions.

Irrigation and Agriculture

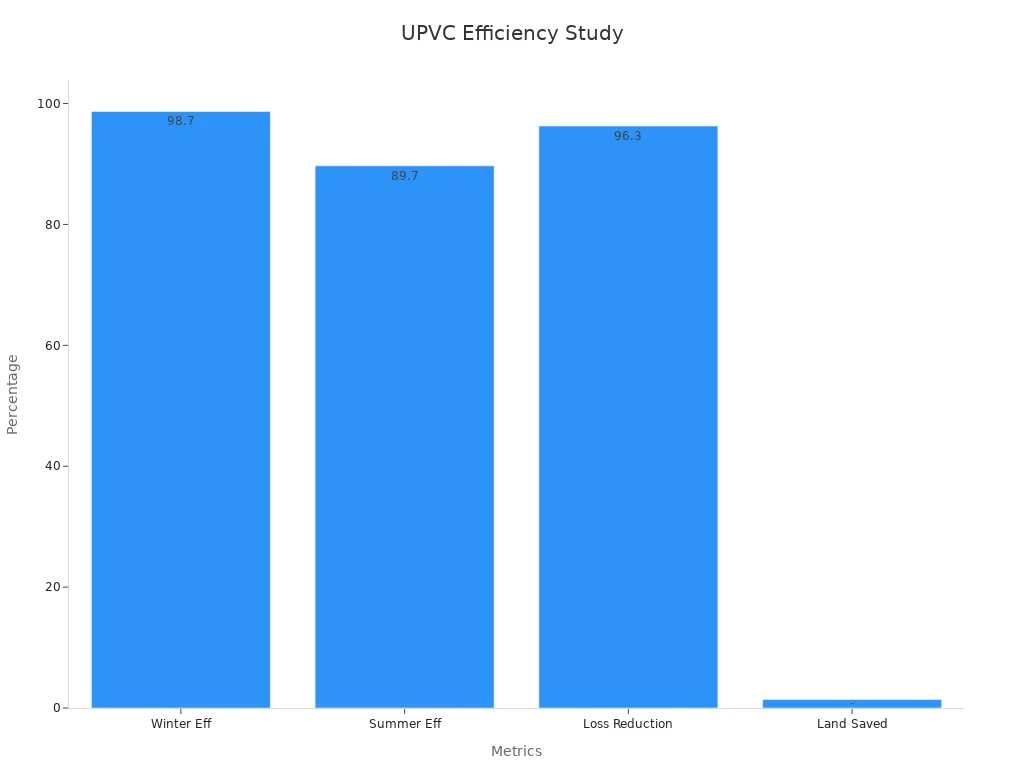

UPVC fittings have transformed irrigation and agricultural water management. Field studies in Egypt demonstrate that UPVC buried pipes achieve the highest water conveyance efficiency, reaching 98.7% in winter and 89.7% in summer. These systems reduce water losses by up to 96.3% and decrease irrigation time by 50-60%. Farmers benefit from increased land availability and higher profits under crop cultivation. The following chart illustrates the efficiency and land-saving advantages of UPVC irrigation systems:

- High conveyance efficiency conserves water resources.

- Reduced installation time and maintenance costs.

- Supports sustainable agriculture and increased crop yields.

Selecting the Right UPVC Fitting

Pipe Size and Pressure Requirements

Selecting the correct pipe size and pressure rating is essential for system safety and efficiency. Engineers use water flow charts, such as those from FlexPVC, to match pipe diameter with flow rate and velocity. These charts help maintain flow within safe ranges, preventing noise and hydraulic shock. The Engineering Toolbox provides pressure rating charts based on ASTM standards like D2241 and D2665. These resources guide users to choose UPVC fittings that meet both mechanical and operational demands. Proper sizing ensures the system avoids damage and delivers reliable performance.

Matching Fittings to Application

Different applications require specific fitting properties. The table below compares UPVC, PVC, and CPVC to help users select the right material for each scenario:

| Aspect | UPVC | PVC | CPVC |

|---|---|---|---|

| Physical Properties | High rigidity, strength, durability | Greater flexibility, affordability | Enhanced heat resistance, chemical tolerance |

| Chemical Resistance | Excellent | Moderate | Superior |

| Typical Applications | High-pressure, underground, industrial | Irrigation, drainage, residential | Hot water, industrial piping |

| Installation Requirements | Professional handling | Solvent welding | Special cement |

| Cost Considerations | Higher initial, long-term savings | Budget-friendly | Higher, long-term savings |

| Environmental Impact | No plasticizers, eco-friendly | Moderate impact | Lower carbon footprint |

UPVC pipes excel in high-pressure and industrial settings due to their strength and corrosion resistance. Users should consider the environment, budget, and long-term needs when choosing a fitting.

Quality and Certification

Quality assurance ensures the reliability of every upvc fitting. Manufacturers use visual inspections and automated systems to detect surface defects. Mechanical tests check tensile strength, impact resistance, and flexural strength. Chemical resistance testing confirms durability against acids and alkalis. Hydraulic tests simulate real-world pressures to verify leak resistance. UV stability assessments guarantee performance outdoors. Compliance with standards like ASTM, ANSI, ASME, and ISO confirms safety and reliability. Regular maintenance and inspection further extend the lifespan of UPVC systems.

Tip: Always check for certification marks and test results before purchasing UPVC fittings to ensure long-term safety and performance.

Installation Tips for UPVC Fitting

Tools and Materials Needed

Proper installation of UPVC fittings requires a few essential tools and materials. Installers should gather the following items before starting the process:

- Pipe cutter or fine-toothed saw for clean, straight cuts

- Deburring tool or file to smooth pipe edges

- Clean cloth for removing dust and debris

- PVC primer to prepare bonding surfaces

- UPVC cement for secure joints

- Measuring tape and marker for accurate cuts

- Optional: Strap wrench for tightening compression fittings

Installers may also use UPVC compression fittings with EPDM seals. These fittings require only a square cut and hand tightening, making the process efficient and reducing the need for adhesives or curing time.

Step-by-Step Installation

A systematic approach ensures a leak-free and durable connection. The following steps outline the standard procedure:

- Measure and mark the pipe to the required length.

- Cut the pipe squarely using a pipe cutter or saw.

- Deburr and clean both the pipe ends and the interior of the fitting.

- Apply PVC primer to all bonding surfaces.

- Spread UPVC cement evenly on the primed areas.

- Insert the pipe into the fitting, twist slightly, and hold for 10–15 seconds.

- Allow the joint to cure for at least 15 minutes before handling. For maximum strength, wait 24 hours before pressurizing the system.

Tip: For compression fittings, insert the pipe and hand-tighten the nut. No adhesive or curing is needed.

Common Mistakes to Avoid

Installers sometimes overlook key details that affect system performance. Common mistakes include:

- Failing to cut pipes squarely, which can cause leaks

- Skipping the cleaning or priming step, leading to weak bonds

- Using too much or too little cement

- Not allowing enough curing time before pressurizing

- Over-tightening compression fittings, which may damage seals

Careful attention to each step ensures every upvc fitting delivers reliable, long-lasting service.

| Aspect | Highlights |

|---|---|

| Key Benefits | Chemical resistance, corrosion immunity, long service life, lightweight, heat resistance |

| Applications | Residential, industrial, irrigation, HVAC, and more |

Selecting the right upvc fitting ensures leak-free, durable plumbing. Leading manufacturers focus on quality and innovation, supporting reliable, sustainable systems for every environment.

FAQ

What is the maximum temperature UPVC fittings can handle?

UPVC fittings withstand temperatures up to 60°C (140°F). They maintain structural integrity and performance within this range.

Are UPVC fittings safe for drinking water systems?

Manufacturers use non-toxic, lead-free materials. UPVC fittings meet international standards for potable water applications.

How long do UPVC pipe fittings typically last?

UPVC fittings often last over 30 years. Their resistance to corrosion and chemicals ensures long-term reliability in most environments.

Tip: Regular inspection extends the service life of any piping system.