How long will a PVC ball valve last?

A PVC ball valve typically lasts between 10 to 20 years, and sometimes even longer. However, the average lifespan for many ball valves is approximately 8 to 10 years. Several critical factors determine the actual lifespan of a PVC ball valve. Understanding these factors is key to maximizing its durability.

Key Takeaways

- PVC ball valves last 10 to 20 years, but many last 8 to 10 years. Good material and proper use help them last longer.

- Heat, pressure, and chemicals can make PVC ball valves wear out faster. Too much sun also harms them.

- Pick the right valve, install it well, and check it often. This helps your PVC ball valve work for many years.

Factors Affecting PVC Ball Valve Lifespan

Several factors significantly influence the lifespan of a PVC ball valve. Understanding these elements helps users make informed decisions for selection, installation, and maintenance, ultimately extending the valve’s operational life.

Material Quality and Manufacturing of PVC Ball Valve

The inherent quality of the PVC material and the manufacturing processes directly determine a valve’s durability. Advanced material engineering and reinforcement techniques enhance the durability of PVC ball valves. Manufacturers modify PVC with materials like glass fibers or mineral fillers. These reinforcements improve tensile and flexural strength by evenly distributing stress across the valve body. This reduces the likelihood of cracking or deformation under load. The reinforced polymer also provides excellent dimensional stability, ensuring the valve maintains its sealing efficiency over extended periods. These processes lead to a significant increase in impact strength, especially in challenging conditions such as low temperatures or fluctuating pressures.

Superior material quality is often indicated by adherence to industry standards and certifications. For example, NSF/ANSI/CAN 61-G certification confirms valves are safe for drinking water applications with minimal health effects. This certification is nationally recognized for all components contacting drinking water. Other important certifications include ISO 9001:2015, ISO, ASTM, BS 3505, BS 4346, ASTM D1785 SCH40/SCH80, DIN, GB, DWV, ASTM D2665, ASTM D2241, ASTM D2729, ASTM F441/F441M, ISO 1452 Series standards, EN ISO 1452, DIN 8061/8062, GB/T 10002 Series standards, AS/NZS 1477, JIS K6741, CSA B137.3, NSF/ANSI 14, and TIS 17-2532/1131-2535. These certifications assure users of the valve’s quality and performance.

Operating Conditions for PVC Ball Valve

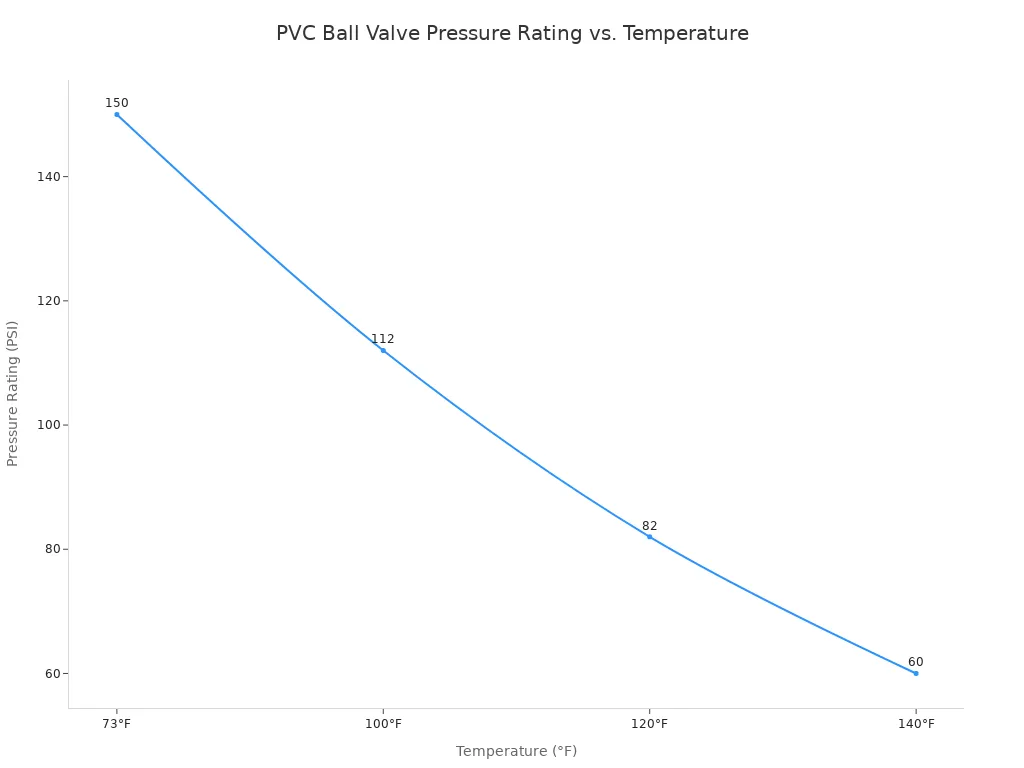

The environmental and operational conditions a PVC ball valve experiences play a crucial role in its longevity. Temperature and pressure are primary considerations. Standard PVC ball valves typically have a maximum pressure rating of 150 PSI at 73°F (23°C), known as the Cold Working Pressure (CWP). The maximum recommended operating temperature for PVC is 140°F (60°C). However, the pressure rating significantly decreases as the operating temperature increases. For instance, at 140°F (60°C), the pressure rating can reduce by 60% to approximately 60 PSI.

| Temperature | Typical Pressure Rating (e.g., for 2″ valve) | Material State |

|---|---|---|

| 73°F (23°C) | 100% (e.g., 150 PSI) | Strong and rigid |

| 100°F (38°C) | 75% (e.g., 112 PSI) | Slightly softened |

| 120°F (49°C) | 55% (e.g., 82 PSI) | Noticeably less rigid |

| 140°F (60°C) | 40% (e.g., 60 PSI) | Maximum recommended temp; significant de-rating |

Continuous operation at high temperatures causes several forms of degradation. Excessive heat can discolor the valve’s outer body or internal components, often appearing darker or more brittle. Overheating causes sealing materials (O-rings, PTFE gaskets, elastomers) to lose elasticity, become brittle, or melt, leading to leaks. Internal components like the valve ball, stem, or actuator housing can warp or crack due to overheating. Frequent temperature extremes cause material expansion and contraction, leading to permanent structural damage and material fatigue. This also decreases the elastic modulus of PVC, impairing sealing properties, and reduces strength and stiffness, affecting pressure resistance. High temperatures can also accelerate the aging or degradation of PVC when exposed to certain chemicals.

Sudden pressure surges, such as water hammer, also impact valve integrity. High-pressure water stresses the valve body, seals, and connections, potentially leading to leaks or even valve failure. Lower temperatures make PVC more brittle, reducing its capacity to absorb shocks. This increases the likelihood of the valve cracking when subjected to sudden impacts or pressure surges. Conversely, higher temperatures soften PVC, compromising its structural integrity and shock-absorbing capabilities. Pressure testing assesses a PVC union ball valve’s shock resistance by simulating rapid pressure changes. Observing the valve’s ability to withstand these sudden pressure spikes without leaking or failing indicates its shock resistance.

Chemical Exposure and Fluid Compatibility for PVC Ball Valve

The type of fluid flowing through the system significantly affects the valve’s lifespan. PVC exhibits chemical inertness, meaning it does not react with the majority of acids, such as hydrochloric and sulfuric acids, or bases. This characteristic ensures PVC ball valves maintain leak-free performance in many chemical applications. However, certain chemicals are incompatible with PVC materials. These include:

- Solvents

- Aromatics

- Chlorinated organic compounds

- Sodium hydroxide (caustic solutions)

- Potassium hydroxide (caustic solutions)

Exposure to these incompatible substances causes rapid degradation, leading to softening, cracking, or complete failure of the valve. Fluid pH levels also influence chemical resistance. An acid with a pH of 2 is significantly more corrosive than a mild acid with a pH of 5, specifically 1,000 times more corrosive. For highly corrosive pH levels (0, 1, 2, and 12, 13, 14), PTFE devices are generally recommended. For mild pH levels (5, 6, 8, 9), polypropylene or PVC devices can be utilized.

UV Exposure and Environmental Factors for PVC Ball Valve

Ultraviolet (UV) radiation, primarily from sunlight, degrades PVC ball valve materials. UV rays cause photodegradation by breaking down the plastic’s molecular structure. This process leads to the oxidation of the material, degrading its molecular structure. The extent of this degradation, which can manifest as discoloration and embrittlement over several years, depends on the intensity and duration of UV exposure. CPVC plastic valves, similar to PVC, are vulnerable to UV degradation when exposed to sunlight for extended periods. This process results in visible and functional issues such as surface discoloration, cracking, and a reduction in tensile strength.

Visible signs of UV damage on an exposed PVC ball valve include:

- Chalking on the surface

- Yellowing on the surface

- Visible cracks, particularly around connection points

Initially, UV degradation manifests as a color change. More significantly, the plastic loses its flexibility and becomes brittle, leading to structural damage such as a handle snapping off or the valve body cracking under normal pressure.

Frequency of Use for PVC Ball Valve

The frequency of opening and closing cycles significantly impacts the lifespan of a ball valve. A valve used in an application close to its pressure/temperature rating and cycled infrequently may last for years. However, the same valve in the same application may require frequent replacement if it is cycled often. Each operation causes wear on internal components, such as the ball and seals. High-frequency usage accelerates this wear, leading to premature failure of the sealing surfaces or mechanical parts. PVC ball valves are valued for their light weight and cost-effectiveness, commonly employed in water and chemical processing. Factors such as the frequency of open/close operation can indicate that a ball valve needs replacement.

Installation Quality for PVC Ball Valve

Proper installation is paramount for the long-term performance of any valve. Improper pipe alignment introduces stress into the system, accelerating wear and potentially causing failure. This misalignment can also create gaps, leading to leaks over time. Large, flangeless valves, including ball valves, are particularly susceptible to piping stresses. These stresses can deform the valve body, hindering proper operation or preventing full contact between the obturator and seating surface. While catastrophic failure is rare, piping loads can impede valve function or lead to internal leakage. Correct installation ensures the valve operates under optimal conditions, free from undue external forces.

Recognizing a Failing PVC Ball Valve

Leaks Around the PVC Ball Valve

Leaks often signal a failing valve. Worn or damaged stem O-rings or seals lose elasticity from regular use, extreme temperatures, or chemical corrosion. High-pressure systems or frequent valve actuation increase wear on these seals. Improper installation, such as incorrect alignment or overtightening, creates uneven pressure on seals. This damages the valve body or causes the valve to shift, leading to leaks at connection points. Sudden pressure increases can force seals to compress beyond capacity, causing deformation. Drastic temperature changes cause materials to expand or contract, weakening seals.

Difficulty Operating the PVC Ball Valve

A PVC ball valve can become stiff or difficult to turn. Debris buildup, corrosion, or wear on the stem or seats contribute to this issue. Dirt or debris accumulates within the valve mechanism. Buildup from water or irrigation systems forms deposits over time. Incorrect sizing or subpar installation can cause internal components to warp or misalign. New valves might feel stiff because factory-fresh PTFE seats are tight against the ball. Mineral buildup from hard water or debris like sand also causes stiffness. Infrequent use allows seals to stick and dry out.

Reduced Flow or Incomplete Closure of PVC Ball Valve

Reduced flow or incomplete closure indicates internal problems. Corrosion on the stem or ball hinders smooth operation. Debris or particles trapped inside the valve prevent smooth rotation. Misaligned ball valves significantly restrict flow or cause complete blockages. Leaks at valve joints and seals result from improper alignment. This places uneven pressure on seals, leading to premature wear. Wear or damage to the valve seat, often from sand or rust, compromises the seal. Deformation of the ball from operating beyond temperature limits prevents proper alignment. Deterioration of seal rings also leads to a loss of elasticity and sealing ability.

Visible Damage to the PVC Ball Valve

Visible damage provides clear signs of failure. A cracked valve body, common in plastic valves exposed to freezing temperatures, indicates failure. Such cracks lead to leaks and can cause complete valve failure under pressure. Discoloration like yellowing or chalking indicates PVC degradation. Yellowing results from surface aging due to UV exposure. Chalking occurs as the material degrades and fillers come to the surface. Severe UV exposure causes chain scission and material embrittlement, a significant form of PVC failure.

Extending Your PVC Ball Valve’s Lifespan

Selecting the Right PVC Ball Valve

Choosing the correct valve for a specific application significantly impacts its longevity. Engineers must consider several critical factors during the selection process. The valve’s published rating must sufficiently cover the maximum fluid temperature and pressure of the process. This includes evaluating the valve body, trim material, seal material, and end connections. Corrosion resistance is another vital aspect. Assess the corrosive effects of chemicals on PVC or CPVC to determine the most suitable valve. CPVC often offers greater corrosion resistance in certain applications. Improper selection can lead to contamination, leaks, and premature valve failure.

The material of seals and ends is also critical. Elastomeric seals provide effective sealing, while plastics like PFA and PTFE offer superior chemical resistance. Consider pressure/temperature ratings, industry standards, seal welding, and installation/maintenance costs for valve ends. Determine if the application requires manual or automatic actuation, and if the actuator will be hydraulic, electric, or pneumatic. Automated valves need sufficient force to overcome static friction and dynamic torque. Finally, select valves that are easy to maintain for application stability and reliability. Ball valves, for instance, resist jamming but are not ideal for precise flow adjustment.

| Component | Material/Type | Characteristics & Application |

|---|---|---|

| Body Material | PVC (Polyvinyl Chloride) | Ideal for water systems, resists acids, bases, salts; not for high temperatures; affordable and lightweight. |

| Seal Material | PTFE (Polytetrafluoroethylene) | Exceptional chemical resistance, high temperatures, high purity applications. |

| PA (Polyamide) | Good mechanical strength, wear resistance, moderate temperatures, cost-effective. | |

| EPDM (Ethylene Propylene Diene Monomer) | Excellent for water and steam, resistant to weathering, ozone, UV; not for oils/hydrocarbons. | |

| FKM (Fluoroelastomer) | Outstanding resistance to high temperatures and wide range of chemicals (oils, fuels); demanding applications. | |

| POM (Polyoxymethylene) | Good mechanical properties, chemical resistance, low friction, high dimensional stability. | |

| Connection Type | Standard/Threaded | Most common for various temperature and pressure applications. |

| Flanged | Used on larger pipes; requires consideration of pressure ratings and flange compression class. | |

| True Union | Easy dismantling for quick repair and maintenance; solvent socket connection. | |

| Compression Ring | For smaller-diameter pipes, allows disassembly/reassembly; tight seal by compressing a ring. | |

| Cutting Ring | Secure, leak-proof seal by cutting into the pipe; common in high-pressure hydraulic systems. | |

| Hose Pillar | For flexible hose attachments; barbed end for low-pressure applications. | |

| Glued Sleeve | Permanent, leak-proof connection for plastic pipes using adhesive. | |

| Welded Sleeve | Permanent, robust connection by welding; for high-pressure/high-temperature industrial settings. |

Key considerations for selection include:

- Operating Pressure and Temperature: The valve’s rating must exceed the maximum system pressure and temperature.

- Media Compatibility: Choose materials compatible with the process fluid to prevent corrosion or degradation.

- Flow Control Requirements: For throttling, consider V-port or trunnion-mounted valves with appropriate actuators.

- Pipeline Size and Layout: Account for full versus reduced bore, port configuration, and available installation space.

- Automation Needs: Decide if the valve requires remote operation or integration into a control system.

- Maintenance and Lifespan: Opt for valves that are easy to maintain and have readily available spare parts.

Proper Installation of PVC Ball Valve

Correct installation is fundamental to a valve’s long-term performance. Following best practices ensures a stress-free setup. First, gather all necessary tools and materials, including the correct size PVC ball valve, pipes, fittings, primer, and cement. Plan the valve’s location, measure accurately, and mark cutting points. Always turn off the main water supply and wear safety gear. Next, make straight, clean cuts on the PVC pipe and remove any burrs to ensure smooth connections.

Perform a dry fit by assembling the valve and fittings without glue first. This confirms proper alignment and fit, ensuring the handle is accessible. For threaded valves, use plumber’s tape. Then, clean pipe ends and valve sockets. Apply PVC primer to both the outside of the pipe and inside of the valve sockets to soften the PVC for better bonding. Afterward, apply solvent cement evenly to both primed surfaces. Quickly insert the pipe into the valve socket with a slight twist and hold firmly for 15-30 seconds. Wipe away any excess cement. Allow the joint to cure for at least 2 hours, or as per product instructions, before testing. Finally, slowly turn the water supply back on and inspect all connections for leaks. Address any leaks promptly. Avoid common mistakes such as skipping primer, incorrect alignment, or rushing the curing time, as premature pressure can weaken joints.

Protecting PVC Ball Valve from UV Radiation

Ultraviolet (UV) radiation significantly degrades PVC materials over time. Protecting the valve from direct sunlight exposure is crucial for extending its lifespan. Installers can use UV-resistant coatings on the valve’s exterior. These coatings create a protective barrier against harmful UV rays. Alternatively, UV-resistant covers can shield the valve from direct sunlight. These covers physically block the radiation, preventing photodegradation and maintaining the material’s structural integrity.

Regular Inspection and Maintenance of PVC Ball Valve

Consistent inspection and maintenance routines are vital for maximizing a valve’s operational life. Proper installation ensures the valve operates correctly from the start, reducing the likelihood of early failure. Regular cleanings prevent debris buildup that can negatively impact performance and material integrity. For non-metal parts like PVC, alcohol- or water-based cleaners are recommended. Valve lubrication maintains smooth operation, prevents abrasion, and enhances seal effectiveness. It is crucial to use lubricants compatible with the valve materials. Routine inspections identify potential issues such as loose hardware, mineral buildup, corrosion, and leaks. They also ensure proper valve function. Annual inspections are ideal, with more frequent checks for high-pressure or high-cycle applications.

Avoiding Over-Torquing the PVC Ball Valve

Over-torquing refers to applying excessive force when tightening a valve or its connections. This practice can severely damage a PVC ball valve. Excessive tightening can crack the valve body, especially around threaded connections, or deform internal components. It also compresses seals beyond their intended limits, leading to premature wear, reduced elasticity, and eventual leaks. Over-torquing can strip threads, making future maintenance or replacement difficult. Always follow manufacturer specifications for torque settings. Use appropriate tools and apply only the necessary force to achieve a secure, leak-free connection.

A combination of factors influences a PVC ball valve’s longevity. These include material quality, operating conditions, and installation. Proper selection, careful installation, and consistent maintenance are crucial for extending its operational life. By diligently following these best practices, your PVC ball valve can perform reliably and efficiently for many years.

FAQ

How often should one inspect a PVC ball valve?

Inspect PVC ball valves annually. For high-pressure or high-cycle applications, more frequent checks are necessary to ensure optimal performance and prevent early failure.

Can PVC ball valves handle hot water?

PVC ball valves handle temperatures up to 140°F (60°C). However, their pressure rating significantly decreases at higher temperatures, impacting performance.

What are the visible signs of UV damage on a PVC ball valve?

Visible signs of UV damage include chalking, yellowing, and cracks on the valve’s surface. These indicate material degradation and embrittlement.