Why we choose pvc ball valve?

PVC ball valves are a top choice for fluid control. They offer a unique blend of durability, cost-effectiveness, and ease of use. These valves provide superior performance and reliability across various applications. Unlike metal valves, a pvc ball valve resists rust, chemical damage, and degradation, ensuring an extended lifespan. Their manufacturing is also cheaper, making them a budget-friendly option for diverse projects.

Key Takeaways

- PVC ball valves last a long time. They do not rust and resist many chemicals. This makes them good for different environments.

- PVC ball valves cost less to buy and install. They are light, so they are easy to put in place. They also need less fixing over time.

- PVC ball valves work well in many places, like water pipes. They are designed to not leak and work smoothly. But, do not use them for air under pressure.

The Unmatched Durability and Resistance of PVC Ball Valve

Exceptional Corrosion Resistance

PVC ball valves offer superior resistance to rust and corrosion due to their plastic composition. This makes them a suitable alternative to metal valves in many corrosive environments. They effectively resist a wide range of aggressive chemicals, ensuring system integrity and preventing premature failure. For instance, these valves demonstrate strong resistance to:

- Chlorine

- Hydrogen peroxide

- Most inorganic acids

- Alkalis

- Salts

This chemical inertness ensures the valves maintain their structural integrity and operational efficiency even when handling harsh substances. However, users must consider the operational limits. PVC ball valves typically have a maximum temperature rating of 60 °C (140 °F). They also operate effectively with a working pressure of 150 PSI (non-shock) at 73°F, making them reliable for various applications within these parameters.

Long Lifespan in Diverse Environments

The inherent durability of PVC contributes significantly to the long lifespan of these ball valves. PVC ball valves generally have a lifespan ranging from 10 to 20 years. However, the typical average lifespan observed for many of these valves is approximately 8 to 10 years. The actual duration of service is significantly influenced by factors such as material quality and proper usage. High-quality PVC ball valves, especially those manufactured from virgin materials and installed correctly, are expected to last between 10 to 20 years. In some cases, they can even match the entire operational life of the piping system they are integrated into. Key determinants of their longevity include the quality of materials used, the specific application, and the environmental conditions they operate in.

PVC ball valves are also known for their resistance to UV radiation, allowing them to endure years of use without degradation when exposed to sunlight. This UV resistance ensures the valves maintain their effectiveness in outdoor plumbing or irrigation systems. However, prolonged exposure to UV light can cause photodegradation in PVC, breaking down chemical bonds and leading to brittleness, discoloration, and cracking. This can result in leaks, reduced strength, and decreased flexibility. To protect PVC true union ball valves from UV light and extend their lifespan, the following methods are recommended:

- Use UV-Resistant PVC: Opt for PVC valves specifically designed with additives to block UV rays and prevent photodegradation.

- Install in a Shaded Area: Position the valve in a location protected from direct sunlight, such as under a tree or building, or use a shade structure/cover.

- Paint the Valve: Apply special UV-resistant paint designed for PVC to block UV rays.

- Use a UV-Resistant Coating: Apply clear, tinted, or reflective coatings to protect against UV light.

- Regular Maintenance: Perform routine checks for damage, replace worn parts, and clean the valve to prevent accumulation of contaminants.

Cost-Effectiveness and Simplified Installation of PVC Ball Valve

Affordable Initial Investment

PVC ball valves present a highly cost-effective solution for fluid control systems. Their initial purchase price offers significant savings compared to metal alternatives. This affordability allows projects to invest in high-quality components without exceeding budget constraints, even for large-scale systems. The table below illustrates the typical cost difference between PVC and metal three-way pneumatic ball valves of similar specifications.

| Feature | PVC 3-Way Pneumatic Ball Valve | Metal 3-Way Pneumatic Ball Valve |

|---|---|---|

| Cost | $300-800 per valve | $600-1,500 per valve |

| Cost Savings | 40-60% less than metal alternatives | N/A |

| Installation Costs | Favored due to 40-50% lighter weight | Higher due to heavier weight |

This substantial cost saving, often 40-60% less than metal valves, makes PVC a preferred choice. The low initial cost does not compromise performance. PVC ball valves frequently outperform metal valves in longevity and resistance to environmental factors.

Lightweight and Easy to Install

The inherent material properties of PVC contribute to the lightweight nature of these valves, simplifying installation processes. Plastic valves, including those made from PVC, are considerably lighter than their metal counterparts. This characteristic makes them easier to handle and install.

| Valve Type | Size | Approximate Weight (pounds) |

|---|---|---|

| Plastic Valve | 1/2-inch | 0.1 – 0.2 |

| Stainless Steel Valve | 1-inch | 1 – 2 |

| Cast Iron Valve | 2-inch | 5 – 10 |

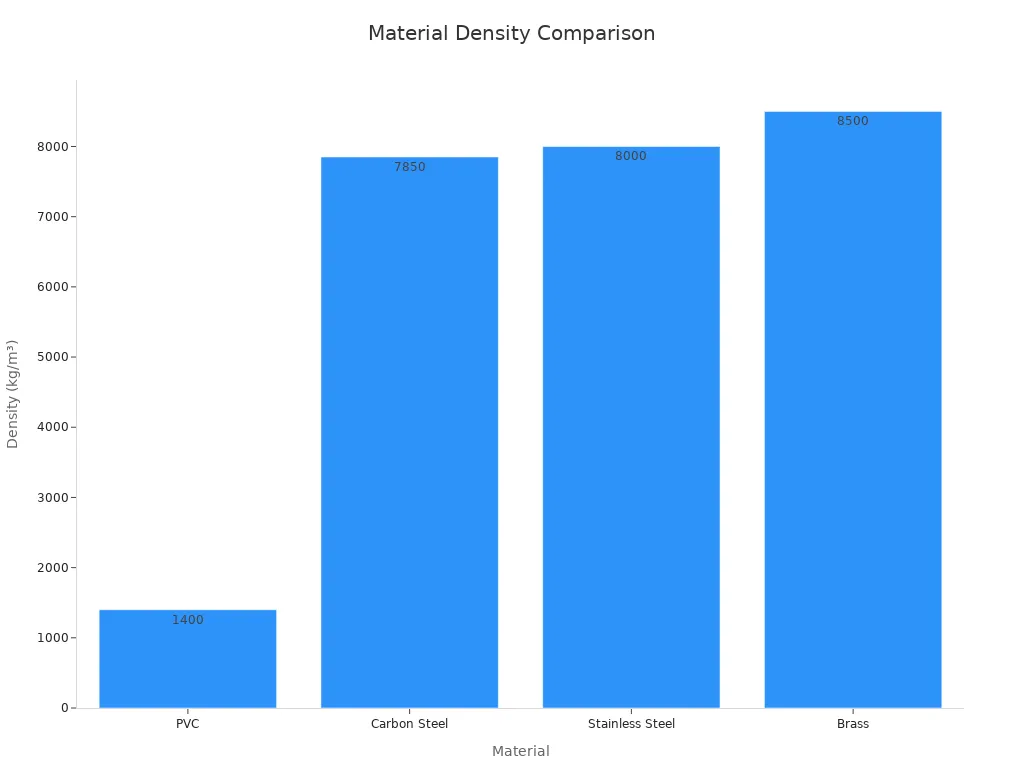

The weight of a ball valve directly correlates with the density of its material. PVC possesses a much lower density compared to metals like carbon steel, stainless steel, or brass. This density difference directly translates into lighter valves.

| Material | Density (kg/m³) |

|---|---|

| PVC | 1,400 |

| Carbon Steel | 7,850 |

| Stainless Steel | 8,000 |

| Brass | 8,500 |

Lighter valves reduce labor requirements and installation costs. They also simplify transportation and handling on job sites. While PVC valves are less suitable for high-pressure or high-temperature applications, their ease of installation provides a significant advantage in many standard fluid control systems.

Reduced Maintenance Requirements

PVC ball valves offer significant long-term cost savings through reduced maintenance and extended operational life. Their corrosion-resistant nature eliminates the need for regular treatments or repairs common with metal valves. This characteristic contributes to a longer lifespan, reducing the frequency of replacements and minimizing disruptions to the fluid supply system.

The smooth, non-reactive surface of PVC ball valves resists scaling and the buildup of minerals and sediments. This contrasts with metal valves, which often accumulate such deposits. Resistance to buildup reduces the need for frequent cleaning and maintenance. It also ensures optimal flow rates and prevents issues that could lead to higher pressure and reduced operational efficiency.

PVC ball valves typically have an estimated service life of 20–25 years when operating within rated conditions. Factors such as pressure cycling, chemical exposure, UV protection, and installation quality influence actual longevity. While the valve body can last for decades, valve seats and seals might require replacement sooner in high-frequency or aggressive applications.

Regular maintenance helps prevent common failure modes and extends the valve’s service life. Continuous use and constant rotation cause wear and tear. Valves can also leak after periods of inactivity. Corrosion of various valve parts also occurs. Understanding these potential failure methods is crucial for proper troubleshooting and preventing system shutdowns.

Recommended maintenance practices include:

- Regular Inspection: Routinely check for visible signs of wear, leaks, or damage. This includes cracks or deformities in the valve body or handle and deterioration of O-rings and seals. Inspect connections for leaks.

- Cleaning: Regularly clean the valve to prevent accumulation of dirt, debris, or chemical residues. Use a soft cloth with warm, soapy water for the exterior. If possible, disassemble the valve to clean internal components.

- Lubrication: Apply silicone-based lubricant to the handle and shaft to ensure smooth operation. Avoid petroleum-based products.

- Leak Checks: Regularly inspect for leaks around the valve body, handle, and connections. Conduct pressure tests if feasible to identify drops in pressure.

- Replacing Worn Parts: Replace O-rings and seals when inspections reveal signs of wear. This involves shutting off water, disassembling the valve, and installing new compatible components.

- Seasonal Maintenance: Perform specific checks based on climate. In cold regions, inspect for brittleness before winter. In warm climates, consider UV-resistant coatings for sun-exposed valves.

- Handling Pressure Changes: Monitor system pressure levels during maintenance to prevent valve failures due to high-pressure spikes.

Proper installation, regular inspections, correct lubrication, and timely replacement of worn parts are essential for preventing issues like inability to shut off, partial closing, sticking, or leakage. Regular cleaning also prevents sediment and dirt buildup. These proactive measures ensure the long-term reliability and cost-effectiveness of PVC ball valves.

Versatility and Reliable Performance of PVC Ball Valve

Wide Range of Applications

PVC ball valves demonstrate remarkable versatility across numerous industries. They are frequently utilized in various fluid handling systems. These applications include:

- Water pipelines

- Gas pipelines

- Oil and gas industry

- Industrial pipes

PVC, a flexible plastic with a smooth surface, facilitates the movement of valve components. This material is valued for its adaptability. Standard PVC ball valves are typically rated for a maximum pressure of 150 PSI at 73°F (23°C). This rating decreases as the operating temperature increases. The pressure rating can be cut in half at 140°F (60°C). Larger diameter valves also tend to have lower pressure ratings than smaller ones due to increased surface area.

| Temperature | Pressure Rating (relative to 150 PSI) | Material State |

|---|---|---|

| 73°F (23°C) | 100% (e.g., 150 PSI) | Strong and rigid |

| 100°F (38°C) | 75% (e.g., 112 PSI) | Slightly softened |

| 120°F (49°C) | 55% (e.g., 82 PSI) | Noticeably less rigid |

| 140°F (60°C) | 40% (e.g., 60 PSI) | Maximum recommended temp; significant de-rating |

Users must note that standard PVC ball valves should never be used for compressed air or any other gas. The maximum recommended air pressure for PVC is zero. Pressurized gas in PVC can lead to shattering and dangerous projectiles if the material fails.

Smooth Operation and Leak-Proof Design

PVC ball valves offer smooth operation and a reliable leak-proof design. Several design features contribute to this performance:

- Valve Body: The main structural framework, made from durable PVC, houses all internal components. Its smooth interior minimizes friction losses. This contributes to efficient fluid movement and ensures pressure stability.

- Floating Ball: A spherical ball with a precisely machined through-hole controls flow. It rotates to open or close the flow path. The ‘floating’ design allows it to press firmly against the downstream seat. This creates a tight, leak-preventing shut-off.

- Valve Seats: Typically made of PTFE or other low-friction polymers, these seats seal around the ball. They allow it to move freely while maintaining leak-proof performance. They resist wear and reduce operating torque, enabling smooth opening and closing.

- Stem and O-Rings: The stem connects the handle to the ball, transferring rotational motion. O-rings around the stem provide a secondary sealing mechanism. This prevents fluid escape and enhances leak-resistance and reliability.

- Handle and Locking Mechanism: The external handle allows for simple, quick operation, often requiring only a quarter turn. Ergonomic designs improve grip and reduce torque. Locking mechanisms prevent accidental operation, ensuring clear and safe use.

- End Connections: Various types (threaded, socket, union) integrate the valve into the piping system. Proper design ensures secure installation, minimizes vibration, and supports long-term sealing stability.

PVC ball valve designs mitigate common leak risks. These risks include faulty components, improper installation, wear and tear, sediment accumulation, and environmental factors. The robust design and material properties of PVC help prevent issues like cracked seats, damaged balls, or compromised stem seals.

PVC ball valves stand out as an ideal solution for efficient and reliable fluid management. Their unique combination of durability, affordability, and ease of use makes them a preferred choice across diverse applications. For your next project, consider the proven benefits of a pvc ball valve.