What Role Do Advanced Molds Play in Flawless Plastic Pipe Fitting OEM?

Advanced molds are fundamental to achieving flawless plastic pipe fitting OEM. They serve as the primary determinant of precision, quality, and efficiency in manufacturing. The design and execution of these molds directly influence the final product’s integrity. For instance, creating Custom plastic pipe fittings OEM relies heavily on superior mold engineering. This ensures consistent dimensions and optimal performance, especially for specialized items like HDPE same floor Drainage fittings. Advanced mold technology forms the bedrock of high-quality production.

Key Takeaways

- Advanced molds make plastic pipe fittings very precise. They ensure the parts fit well and work correctly.

- These molds help make strong and lasting pipe fittings. They add special features to make them robust.

- Advanced molds make factories work faster and waste less material. This helps make many good parts quickly.

- Molds help pipe fittings meet important safety rules. This ensures the parts are safe and reliable for a long time.

Precision Engineering in Advanced Molds for Custom Plastic Pipe Fittings OEM

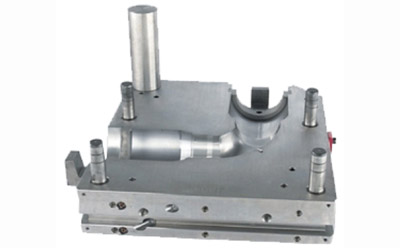

Advanced molds represent the cornerstone of precision engineering in the manufacturing of plastic pipe fittings. Their design and construction directly dictate the quality and performance of the final product. Achieving flawless results requires meticulous attention to detail throughout the mold-making process.

Ensuring Dimensional Accuracy and Consistency

Dimensional accuracy is paramount for plastic pipe fittings, ensuring proper fit and function within complex systems. Advanced molds meticulously control part dimensions, preventing common issues like flash, warpage, and inconsistent wall thickness. Material-related factors, such as lower-viscosity materials like PBT or PA66, can seep into small mold gaps, creating flash. Improper material handling, including insufficient drying, also increases defect likelihood. Mold-related factors, such as poor alignment and worn parting lines, lead to material leakage. Inadequate venting causes gas buildup, increasing back pressure and forcing material into unintended gaps. Process-related factors, like high injection pressure and holding force, result in overpacking and flash, while insufficient clamping force allows mold separation.

Advanced molds mitigate these challenges through precise construction and maintenance. They feature tight tolerances, typically within ±0.01 mm, and consistent parallelism of mold plates, which prevents gaps. Optimizing mold closure involves high-precision mold bases and balanced clamping to prevent uneven closing. Accurate component fit, achieved through polishing and fitting techniques, along with reinforced guide pins and bushings, ensures complete contact and repeatable alignment. Regular inspection and maintenance prevent wear; technicians routinely check parting lines, cavities, and mold surface finish for wear or dents. Preventive maintenance includes lubricating moving parts and repairing parting lines to restore sealing precision. Implementing proper venting avoids gas traps. Strategically placed vents, 0.02 mm to 0.05 mm thick, at flow path ends and areas prone to air entrapment, prevent pressure buildup. Continuous vent cleaning and the use of vacuum venting systems for complex parts actively remove trapped air.

Optimizing holding time and pressure also plays a critical role. Excessive holding pressure causes overpacking, forcing material into mold gaps and creating flash. Prolonged holding time increases the chance of material seeping through mold gaps and may cause part deformation. Conversely, insufficient holding pressure results in incomplete cavity filling. Advanced molding processes utilize gradual pressure reduction, often a two-stage holding phase, and calibrate holding time based on part thickness and material shrinkage. This maintains consistent holding pressure throughout the molding cycle, ensuring dimensional stability for Custom plastic pipe fittings OEM.

Optimizing Material Flow and Distribution

Optimizing material flow and distribution within the mold cavity is crucial for producing high-performance plastic pipe fittings. Engineers utilize advanced simulation software to visualize the injection process before mold production. This identifies weak points, pressure imbalances, or cooling issues. Mold flow analysis predicts plastic behavior under heat and pressure, enabling adjustments that increase mold life and part quality. Key simulation software includes SimForm, Moldflow (by Autodesk), and MoldEx3D. The HxGN Mould and Die Suite, which provides integrated workflows for moldmaking, also supports this optimization with tools like VISI, WORNC, NCSIMUL, and datanomix.

Conformal cooling techniques, involving channels that follow the contour of the mold cavity, provide uniform cooling. This prevents warping and improves surface finish, leading to shorter cycle times, improved part quality, and longer mold life. Optimized material distribution, particularly influencing wall thickness, uniformity, and glass fiber orientation, directly impacts the pressure resistance performance of pipe fittings. Thicker and more uniform wall thickness, resulting from better material distribution, enhances the ability to resist water pressure surges and improves overall pressure resistance. Improved orientation of glass fibers within the melt, achieved through optimized processing methods, increases circumferential strength. This contributes to better pressure resistance by forming a tight, three-dimensional cross structure that disperses external forces effectively. Precise control of injection speed and pressure leads to superior mechanical properties and fittings free from internal defects like air entrapment or premature solidification. Careful control of material flowability ensures dimensional accuracy, crucial for compatibility and long-term performance.

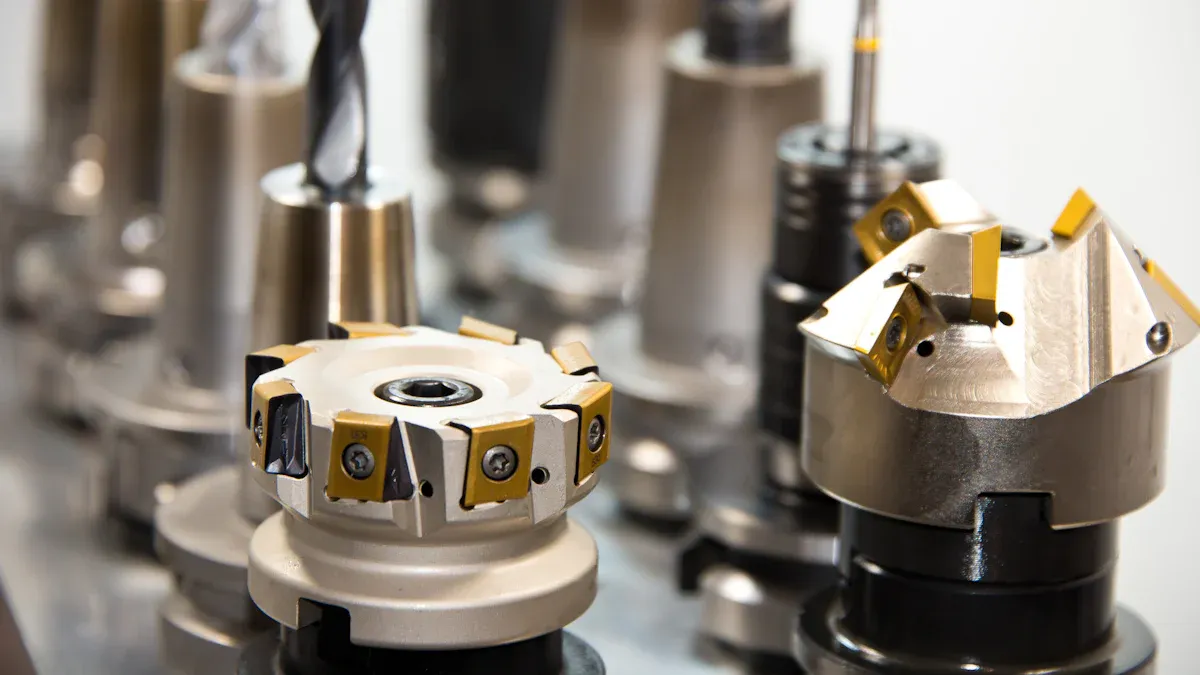

Advanced Machining and Finishing Techniques

The surface quality and durability of advanced molds significantly impact the final plastic pipe fitting. Advanced machining and finishing techniques are essential for achieving superior mold surfaces. Polishing reduces surface roughness, which improves molten plastic flow for uniform distribution and better filling, resulting in fewer voids or defects. It also facilitates easy release of molded parts by reducing friction. A high-quality mirror polish is particularly useful for achieving high-gloss finishes on the pipe fittings.

Various coatings and treatments further enhance mold performance and longevity. Chrome plating offers excellent corrosion resistance against moisture, chemicals, and oxidation. It also enhances wear resistance against high pressures and friction during injection molding, extending mold lifespan. Chrome plating improves release properties due to its smooth, non-sticky surface. Nitriding, a thermochemical treatment, diffuses nitrogen into the surface, forming a hard nitride layer. This significantly improves hardness, wear resistance, and fatigue strength. Nitriding provides good corrosion resistance and improves dimensional stability by minimizing distortion during treatment. PVD (Physical Vapor Deposition) coatings, such as Titanium Nitride (TiN), deposit a thin film that offers excellent hardness, wear resistance, and a low friction coefficient. PVD coatings reduce adhesion between plastic and mold, improving the release of pipe fittings and contributing to consistent part quality.

Enhancing Performance and Durability in Custom Plastic Pipe Fittings OEM

Advanced molds significantly elevate the performance and durability of plastic pipe fittings. They achieve this by meticulously controlling surface quality, internal structure, and overall strength. This precision ensures the fittings meet rigorous demands in various applications.

Achieving Superior Surface Finish and Internal Geometry

Advanced molds are critical for achieving a superior surface finish and precise internal geometry in plastic pipe fittings. Precision molds feature smooth cavity surfaces. These smooth surfaces minimize defects such as roughness, weld lines, or uneven textures on the pipe fittings. A smoother inner surface reduces friction losses, which is crucial for efficient fluid transport. High-quality surface finishes prevent the accumulation of deposits, thereby avoiding blockages and maintaining system efficiency. Advanced engineering in mold design includes precision multi-cavity molds. Manufacturers utilize CNC-machined cores to ensure a smooth surface finish. These CNC-machined cores achieve a tight tolerance of ±0.01mm, directly contributing to the superior surface quality.

Precise internal geometry control in plastic pipe fittings offers significant benefits for fluid dynamics and pressure resistance. For example, sanitary wyes feature internal geometry designed to prevent solids accumulation and promote self-cleaning. This design is critical for consistent flow in gravity-fed drainage systems. Long-radius elbows offer gentler curves to minimize pressure drop. This leads to reduced energy consumption and extended system life due to smoother flow, especially in high-velocity or pump-discharge applications. Sanitary tees incorporate specialized internal geometry to promote smooth flow transitions, minimize turbulence, and eliminate dead zones where debris could accumulate. This ensures consistent flow characteristics and high hygiene standards. Precise internal geometry control in PVC pipe fittings distributes stress evenly. It prevents localized weak points and maintains consistent material density. This engineering ensures internal pressure remains within the material’s long-term strength limits. Consistent manufacturing quality, including precise control of wall thickness and smooth internal surfaces achieved through advanced molding techniques, reduces internal stress. This contributes to stable performance under continuous pressure, thereby enhancing pressure resistance over time.

Strengthening Structural Integrity and Longevity

Advanced mold designs significantly enhance the structural integrity and long-term durability of plastic pipe fittings. Integrating efficient cooling systems reduces cycle times and improves part quality. Draft angles of 1-2 degrees ensure smooth ejection of parts. Uniform wall thickness is crucial to avoid warping and achieve consistent quality. Strategically placed vent holes allow air to escape and prevent defects. Rib designs should maintain a maximum thickness of 75% compared to adjacent walls to prevent issues. Incorporating proper radii enhances both aesthetics and structural integrity of molded parts.

Other mold design features also contribute to robust fittings. Draft angles facilitate part removal, with a minimum of 0.5° recommended for textured surfaces. Wall thickness should be uniform to prevent warping, which directly contributes to structural integrity. Ribs and bosses provide structural support, with a maximum thickness of 60% of adjacent walls to avoid defects. Radii aid in stress distribution, with a minimum of 0.5mm for internal corners to prevent stress concentrations. Cooling system design is crucial for consistent cycle times and part quality. This involves uniform channel distance, balanced flow, and strategic baffle placement. These elements collectively ensure the production of durable and reliable Custom plastic pipe fittings OEM.

Incorporating Reinforcement Features for Robustness

Advanced molds allow for the precise incorporation of reinforcement features, significantly increasing the robustness of plastic pipe fittings. Ribs and gussets are common reinforcement features. These structural elements are strategically placed within the mold design. They provide additional strength and rigidity to critical areas of the fitting. The thickness range for these reinforcement features typically falls between 0.5 mm to 3 mm. This precise control over their dimensions ensures optimal structural support without introducing material inconsistencies or sink marks. By integrating these features, molds produce fittings that withstand higher pressures, greater mechanical stress, and prolonged use in demanding environments.

Driving Manufacturing Efficiency and Reducing Defects for Custom Plastic Pipe Fittings OEM

Advanced molds are pivotal for enhancing manufacturing efficiency and reducing defects in plastic pipe fitting production. They streamline processes and ensure high-quality output.

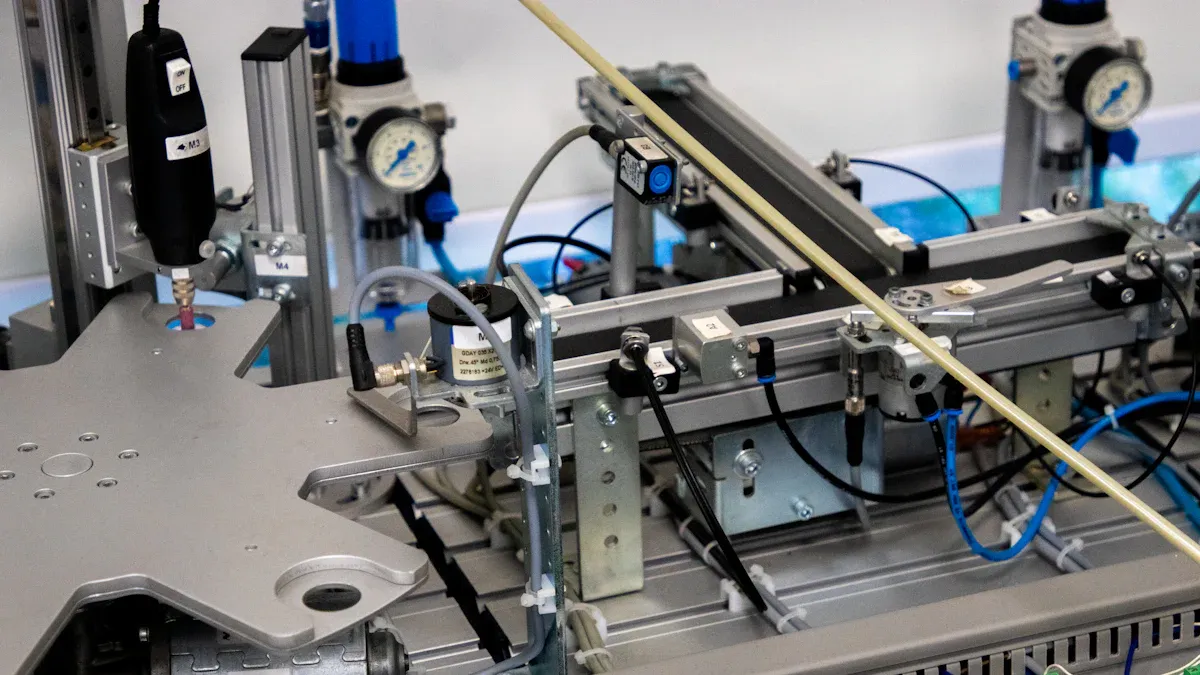

Accelerating Cycle Times and Production Rates

Advanced molds significantly boost manufacturing efficiency. They accelerate cycle times and production rates for Custom plastic pipe fittings OEM. Conformal cooling channels, integrated into tool steel, reduce cycle times. They also minimize warpage. This technology ensures superior flatness for critical components. This is crucial for robust designs and meeting stringent requirements. Hot-runner systems, especially in multi-cavity molds, enhance cycle efficiency. They eliminate cold runners. They reduce material waste by up to 30%. Hot runners maintain molten material flow directly to each gate. Cooling channels within the mold regulate temperature for even part solidification. Hot runner molds offer a shorter cycle compared to cold runner molds. They also have almost no material waste. These systems provide fast cycle times. They improve consistency and quality of molded parts. They reduce material waste compared to cold runners. Hot runners are ideal for large-size fabrication. They require lower injection pressure. They offer more process control and fine-tuning in manufacturing.

Minimizing Material Waste and Post-Processing

Advanced molds also minimize material waste and post-processing needs. Hot-runner systems directly contribute to this. They eliminate the need for a runner system that would otherwise become waste. This significantly reduces material consumption. It also removes the step of separating runners from parts. This saves labor and time. The precision of advanced molds reduces defects. This means fewer rejected parts. It also means less need for secondary finishing operations. This streamlines the production process.

Ensuring Consistent Part Ejection and Quality Control

Consistent part ejection is vital for maintaining quality and preventing damage. Advanced molds employ various ejection mechanisms. Air ejection uses compressed air. It pushes the part away. This method suits smaller, simpler parts. However, it can damage delicate features of larger or complex parts. Ejector pins push the part out after cooling. They are effective for most geometries. Yet, they leave witness marks. These marks may require additional finishing. This can impact part integrity or aesthetics. The stripper plate mechanism slides or lifts the part off the core. It uses mechanical force and precision. This minimizes direct contact. It reduces the risk of damage or deformation. Stripper plates provide excellent surface finish. They eliminate ejector pin marks. They are versatile for various part sizes and shapes. This includes delicate or precision parts. They improve efficiency with controlled, automated stripping. This ensures consistent quality control for every fitting.

Guaranteeing Long-Term Reliability and Compliance in Custom Plastic Pipe Fittings OEM

Advanced molds are essential for ensuring the long-term reliability and compliance of plastic pipe fittings. They build products that perform consistently and meet strict industry requirements.

Sustained Performance Under Diverse Conditions

Advanced molds ensure plastic pipe fittings perform reliably under various conditions. They achieve precision and consistency in manufacturing. This ensures tight tolerances for proper fit and function. Advanced manufacturing technologies, including CAD and CNC machining, enable precise mold design and accurate machining of mold components. This maintains tight tolerances. Real-time process monitoring minimizes variability. It ensures consistent product quality. For fluid systems with constant pressure, part characteristics like wall thickness and reinforcement features are critical. Molders prioritize designing parts to ensure structural integrity. They minimize stress concentrations. This enhances performance under operating conditions.

Resistance to Environmental Stressors

Advanced molds facilitate the creation of pipe fittings resistant to environmental stressors. CPVC piping material is engineered for enhanced UV resistance. It incorporates advanced materials like carbon black and titanium dioxide. These additives act as UV stabilizers. They absorb and dissipate harmful UV radiation. This ensures the material’s essential properties remain intact. HDPE pipe fittings are also engineered with strong UV resistance. They incorporate carbon black or other UV stabilizers during production. These stabilizers absorb harmful UV rays. They prevent penetration of the polymer structure. This extends service life. Plasma treatment and protective coatings further enhance resistance. Plasma treatment modifies the UPVC surface. It increases antioxidant and anti-UV properties. Coating treatments create a physical barrier. This shields the material from sunlight, oxygen, and moisture.

Adherence to Industry Standards and Certifications

Advanced molds play a crucial role in adhering to industry standards and certifications. They produce high-quality components that meet industry standards. High precision ensures accurate and reliable fittings. Durable materials provide consistent performance over time. Efficient production reduces cycle times and increases output. This helps meet relevant standards and regulations. Compliance with standards like ASTM, ISO, and local building codes is crucial. Regulatory bodies often require testing for pressure resistance, chemical compatibility, and safety. Advanced molds, through their precision and consistency, help produce parts that consistently meet dimensional and quality requirements mandated by regulatory bodies. This includes standards like ISO 9001 for quality management systems and NSF/ANSI for public health and safety.

Advanced molds are indispensable for meeting and exceeding industry standards in plastic pipe fitting OEM. Advanced molding techniques enhance product precision and quality, achieving tighter tolerances and better surface finishes. This ensures consistent production for large quantities. Investing in advanced mold technology offers crucial competitive advantages. It reduces labor costs and increases efficiency. This allows manufacturers to produce unique shapes for specific applications. Advanced molds are central to the success and innovation of Custom plastic pipe fittings OEM. They promise improved performance, greater durability, and ease of installation.

FAQ

What defines an “advanced mold” in plastic pipe fitting OEM?

Advanced molds incorporate precision engineering, simulation software, and specialized materials. They feature conformal cooling, hot-runner systems, and advanced machining. These elements ensure superior dimensional accuracy, material flow, and surface finish for pipe fittings.

How do advanced molds contribute to the durability of plastic pipe fittings?

Advanced molds strengthen structural integrity. They achieve this through uniform wall thickness, optimized material distribution, and integrated reinforcement features like ribs and gussets. This design ensures fittings withstand high pressures and environmental stressors.

What role do advanced molds play in reducing manufacturing defects?

Advanced molds minimize defects by optimizing material flow and distribution. They ensure consistent part ejection and precise temperature control. This reduces issues like flash, warpage, and internal voids, leading to higher quality products.

How do advanced molds help meet industry standards and certifications?

Advanced molds produce components with high precision and consistency. This ensures fittings meet strict dimensional and performance requirements. They facilitate compliance with standards like ASTM, ISO, and NSF/ANSI, crucial for regulatory approval.