What is the difference between pvc ball valve and cpvc ball valve?

CPVC ball valves withstand significantly higher temperatures than PVC ball valves. This fundamental difference dictates their suitability for various fluid handling systems. Engineers select the appropriate valve based on the specific thermal demands of an application. A cpvc ball valve offers enhanced heat resistance. A pvc ball valve remains ideal for general cold-water uses.

Key Takeaways

- PVC ball valves work best for cold water and cost less. They cannot handle hot water or strong chemicals.

- CPVC ball valves handle hot water and many chemicals better. They cost more than PVC valves.

- Choose the right valve based on water temperature and chemicals. This helps your system work well and last longer.

Temperature Tolerance: PVC Ball Valve vs. CPVC Ball Valve

Temperature tolerance stands as a primary differentiator between PVC and CPVC ball valves. This characteristic directly influences their suitability for various fluid transport applications. Understanding these limits helps engineers select the correct valve for system longevity and performance.

PVC Ball Valve Temperature Limits

PVC ball valves perform optimally in cold water applications. Generally, the upper limit for PVC pipe is 60 degrees Celsius (140 degrees Fahrenheit). Beyond this temperature, PVC material begins to lose its structural integrity. For instance, the Smith-Cooper International 9122 series pvc ball valve has a maximum operating temperature of 110 degrees Fahrenheit.

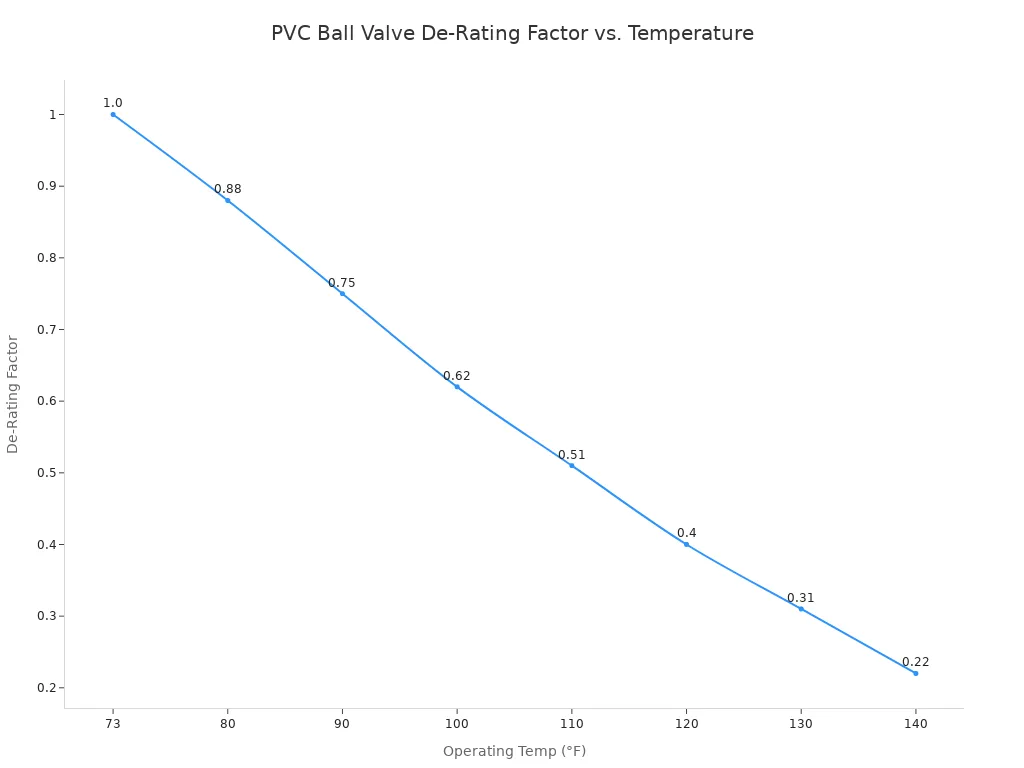

As temperatures increase, the pressure PVC can withstand significantly decreases. This phenomenon is known as de-rating. The optimal temperature for PVC fittings, including Schedule 40 and 80, is 73 degrees Fahrenheit. At this temperature, the material maintains its full pressure rating. However, as the temperature rises, the de-rating factor reduces the allowable pressure.

| Operating Temp (°F) | De-Rating Factor |

|---|---|

| 73 | 1.00 |

| 80 | 0.88 |

| 90 | 0.75 |

| 100 | 0.62 |

| 110 | 0.51 |

| 120 | 0.40 |

| 130 | 0.31 |

| 140 | 0.22 |

The chart below visually represents this de-rating effect.

This chart clearly illustrates how PVC’s pressure capacity diminishes with increasing temperature.

CPVC Ball Valve Temperature Capabilities

CPVC ball valves offer superior temperature capabilities compared to their PVC counterparts. This makes them suitable for hot water and higher-temperature industrial processes. CPVC handles hot water up to 93 degrees Celsius (200 degrees Fahrenheit). This represents a significant advantage over PVC’s 60 degrees Celsius (140 degrees Fahrenheit) limit.

The main difference in temperature tolerance becomes evident when comparing their performance across various temperature ranges.

| Temperature | PVC Performance | CPVC Performance |

|---|---|---|

| Below 60°C (140°F) | Excellent | Excellent |

| 60-82°C (140-180°F) | Begins softening | Stable |

| Above 93°C (200°F) | Fails completely | Maximum rating |

This table highlights CPVC’s stability in temperature ranges where PVC begins to soften or completely fails. CPVC’s enhanced heat resistance allows its use in applications like residential hot water lines and certain chemical processing systems.

Chemical Resistance: PVC Ball Valve vs. CPVC Ball Valve

Chemical resistance is another critical factor distinguishing PVC and CPVC ball valves. This property determines their suitability for transporting various fluids, especially in industrial and chemical processing environments. Engineers must carefully assess the chemical composition of the fluid to prevent material degradation and system failure.

PVC Ball Valve Chemical Compatibility

PVC ball valves demonstrate good resistance to many common chemicals, making them suitable for a wide range of applications. However, specific substances can cause significant degradation. Solvents, aromatics, and chlorinated organic compounds are known to attack PVC material. Additionally, strong caustic solutions like sodium hydroxide and potassium hydroxide can degrade PVC over time.

Beyond chemical exposure, ultraviolet (UV) radiation, primarily from sunlight, also degrades PVC ball valve materials. This photodegradation breaks down the plastic’s molecular structure. It leads to oxidation, discoloration, and embrittlement, compromising the valve’s integrity and lifespan. Therefore, outdoor applications often require UV-stabilized PVC or alternative materials.

CPVC Ball Valve Chemical Durability

CPVC ball valves offer superior chemical durability compared to their PVC counterparts. The additional chlorination process enhances CPVC’s molecular structure, providing greater resistance to a broader range of aggressive chemicals. This makes CPVC a preferred choice for applications involving more corrosive fluids.

UPVC (Unplasticized Polyvinyl Chloride) is a rigid, unplasticized version of PVC. It is stronger and more durable than regular PVC. Unlike PVC, manufacturers do not soften UPVC with plasticizers. This makes it stiffer and more resistant to chemical exposure. UPVC has a dense molecular structure. This structure provides excellent resistance to corrosion, abrasion, and chemical attacks. It is ideal for applications involving aggressive fluids like acids and alkalis. UPVC ball valves are resistant to many acids, including hydrochloric acid, sulfuric acid, and nitric acid. They also remain resistant to alkaline substances such as sodium hydroxide and potassium hydroxide. This enhanced resistance allows CPVC ball valves to perform reliably in demanding chemical processing and industrial settings where PVC would quickly fail.

Material Composition and Properties

Understanding the fundamental material composition of PVC and CPVC reveals why they possess different performance characteristics. The molecular structure dictates their suitability for various applications.

Understanding PVC Ball Valve Material

Polyvinyl Chloride, or PVC, is a widely used plastic polymer. Its composition significantly influences its properties. Approximately 57% of PVC’s mass consists of chlorine. This high chlorine content gives the polymer distinct properties compared to structurally related materials like polyethylene. For instance, PVC’s density, at 1.4 g/cm³, is higher than polyethylene’s (0.88–0.96 g/cm³) due to these chloride groups. In the PVC backbone structure, a chlorine atom replaces a hydrogen atom. This larger chlorine atom significantly affects the backbone’s stiffness. The presence of this halogen atom (chlorine) on the backbone also provides unique chemical resistance properties to a pvc ball valve. Molecular weight is a critical element directly related to the molecular structure; it impacts mechanical properties and processing behavior.

The Chlorination Process of CPVC Ball Valve

CPVC, or Chlorinated Polyvinyl Chloride, undergoes an additional chlorination process after PVC is manufactured. This process introduces more chlorine atoms into the PVC polymer chain. The increased chlorine content, typically ranging from 63% to 69%, further modifies the material’s molecular structure. This modification enhances CPVC’s ability to withstand higher temperatures and resist a broader spectrum of chemicals. The additional chlorine atoms create a more tightly packed and stable molecular structure. This increased stability directly translates to improved thermal and chemical durability. Modifications like controlling the position of the chlorine atom or increasing chlorine content, as in CPVC, significantly alter the material’s properties, making it suitable for more demanding environments.

Pressure Ratings and Performance

Pressure ratings are crucial for selecting the correct ball valve. They dictate the maximum internal pressure a valve can safely withstand during operation. Both PVC and CPVC ball valves have distinct pressure performance characteristics.

PVC Ball Valve Pressure Capabilities

PVC ball valves are suitable for various low-pressure applications. A standard Schedule 40 pvc ball valve typically handles a maximum of 150 PSI (Pounds per Square Inch) at 73°F (23°C). This pressure rating represents its maximum safe working pressure at room temperature. However, temperature significantly impacts PVC’s pressure capabilities. As the fluid temperature increases, the material softens, and its ability to withstand pressure decreases.

The table below illustrates how the maximum pressure rating for a 150 PSI valve changes with water temperature:

| Water Temperature | Max Pressure (for a 150 PSI Valve) |

|---|---|

| 73°F (23°C) | 150 PSI |

| 100°F (38°C) | 93 PSI |

| 120°F (49°C) | 60 PSI |

| 140°F (60°C) | 33 PSI |

This reduction in pressure capacity at higher temperatures makes PVC unsuitable for hot water or high-pressure systems.

CPVC Ball Valve Pressure Performance

CPVC ball valves offer superior pressure performance, especially at elevated temperatures. The enhanced molecular structure of CPVC allows it to maintain higher pressure ratings across a broader temperature range. While CPVC valves also experience some de-rating with increasing temperature, their pressure retention is significantly better than PVC. For example, a CPVC valve rated for 100 PSI at 73°F might still handle 50 PSI at 180°F. This characteristic makes CPVC ball valves ideal for industrial processes and hot water distribution systems where consistent pressure performance at higher temperatures is essential. Engineers often specify CPVC for applications demanding both heat and pressure resistance.

Cost Implications of PVC Ball Valve and CPVC Ball Valve

Cost often plays a significant role in material selection for fluid handling systems. Engineers must balance initial investment with long-term performance and maintenance. PVC and CPVC ball valves present different financial considerations.

PVC Ball Valve Pricing Factors

PVC ball valves are generally more affordable, making them a popular choice for budget-conscious projects. Advancements in polymer technology and automated production processes have significantly reduced manufacturing costs for these valves. These innovations led to a 15-20% reduction in production expenses over the last five years. This cost-cutting directly contributes to the lower manufacturing cost of a pvc ball valve. The inherent affordability of these valves, with prices typically ranging from $0.10 to $8.00 per piece, allows businesses to optimize their budgeting effectively. This competitive pricing makes PVC ball valves a cost-efficient choice for various applications, especially those with less demanding environmental conditions.

CPVC Ball Valve Cost Considerations

CPVC ball valves typically carry a higher price tag than their PVC counterparts. The additional chlorination process required to produce CPVC material contributes to this increased cost. This process enhances the material’s thermal and chemical resistance, but it also adds to manufacturing expenses. Therefore, the initial investment for CPVC systems is usually greater. However, the enhanced durability and performance of CPVC in high-temperature or chemically aggressive environments can lead to long-term savings. These savings come from reduced maintenance, fewer replacements, and improved system reliability. Project managers weigh the higher upfront cost against the extended lifespan and superior performance in demanding applications.

Typical Applications for Each Ball Valve Type

Common Uses for PVC Ball Valve

PVC ball valves serve numerous applications where cold water and cost efficiency are primary considerations. They are a common fixture in residential plumbing for cold water lines and non-potable cold water applications. Installers frequently utilize them in irrigation systems, swimming pool plumbing, and drainage lines. A pvc ball valve effectively manages the flow of cold water in these settings. They also appear in various utility and agricultural systems where fluid temperatures consistently remain below 140°F (60°C). Their straightforward installation, lightweight nature, and resistance to corrosion in cold environments make them a practical and economical solution for many general-purpose fluid control needs, including light industrial processes and recreational water features.

Ideal Applications for CPVC Ball Valve

CPVC ball valves excel in more demanding environments, particularly those involving higher temperatures and aggressive chemicals. Their enhanced chemical resistance makes them indispensable for chemical processing pipelines, where they safely handle a wide array of corrosive substances. They also find widespread use in pharmaceutical applications, where material purity, chemical compatibility, and sterilization processes are critical. Furthermore, CPVC ball valves are the preferred choice for hot water applications, including residential and commercial hot water distribution systems. They reliably handle temperatures up to 90°C (194°F). This superior temperature tolerance and chemical durability allow CPVC valves to perform effectively where PVC would quickly degrade, ensuring system integrity, operational safety, and long-term reliability in critical infrastructure.

Installation and System Compatibility

Proper installation ensures the longevity and performance of any fluid handling system. Both PVC and CPVC ball valves require specific joining techniques and careful consideration of material compatibility.

Joining PVC Ball Valve Systems

Installers primarily use solvent welding to join PVC ball valve systems. This method creates a permanent, leak-proof bond. First, apply PVC primer to the outside of the pipe and inside of the valve sockets. This softens the PVC for better bonding. Next, apply solvent cement evenly to both primed surfaces. Quickly insert the pipe into the valve socket, twisting slightly to spread the cement. Hold the connection firmly for 15–30 seconds to set it. Wipe away any excess cement with a rag. Threaded connections also exist, allowing for disassembly, but they require Teflon tape or paste for proper sealing. Overtightening can crack the plastic fitting. A pvc ball valve system relies on these precise methods for secure connections.

Connecting CPVC Ball Valve Systems

CPVC ball valve systems utilize similar solvent welding techniques as PVC, but they require CPVC-specific primer and cement. The CPVC solvent cement is formulated to withstand higher temperatures and chemical exposures, matching the material’s enhanced properties. Installers follow a similar process: clean, prime, cement, and join. This ensures a robust, leak-free connection capable of handling the more demanding conditions for which CPVC is designed.

Material Compatibility with Other Components

System designers must consider material compatibility when integrating PVC or CPVC valves with other components. PVC systems are incompatible with certain substances. These include some solvents, aromatics, and chlorinated organic compounds. Temperatures exceeding 140°F (60°C) also cause degradation. High-pressure systems exceeding 150 PSI and concentrated organic solvents like acetone or toluene are also unsuitable for PVC. CPVC offers broader compatibility due to its enhanced chemical resistance. However, always verify compatibility with specific chemicals and operating conditions to prevent system failure.

CPVC ball valves excel in hot water and aggressive chemical applications, offering superior performance. A pvc ball valve provides a cost-effective solution for general cold water and drainage systems. Project requirements ultimately dictate the appropriate ball valve selection, balancing performance needs with budgetary considerations for optimal system design.

FAQ

Can I use a PVC ball valve for hot water?

No, PVC ball valves are not suitable for hot water. They begin to soften and lose structural integrity above 140°F (60°C). Use CPVC for hot water applications.

Which valve offers better chemical resistance?

CPVC ball valves offer superior chemical resistance. The additional chlorination process enhances their durability against a broader range of aggressive chemicals compared to PVC.

Is CPVC more expensive than PVC?

Yes, CPVC ball valves typically cost more than PVC ball valves. The specialized manufacturing process for CPVC contributes to its higher price point.