What is the difference between ball valve and union ball valve?

Ball valves and union ball valves serve crucial roles in fluid control systems. A standard ball valve provides on-off control, while a union ball valve includes a union fitting for easy disassembly. This feature simplifies maintenance and repairs, highlighting the distinct advantages of the union ball valve in various applications.

Key Takeaways

- Ball valves provide reliable on-off control for fluid flow, while union ball valves allow for easy disassembly, making maintenance simpler.

- Union ball valves reduce downtime during repairs due to their design, which enables quick access to internal components without cutting pipes.

- When choosing a valve, consider factors like design complexity, maintenance needs, and the specific application to ensure optimal performance.

Definition of Ball Valve

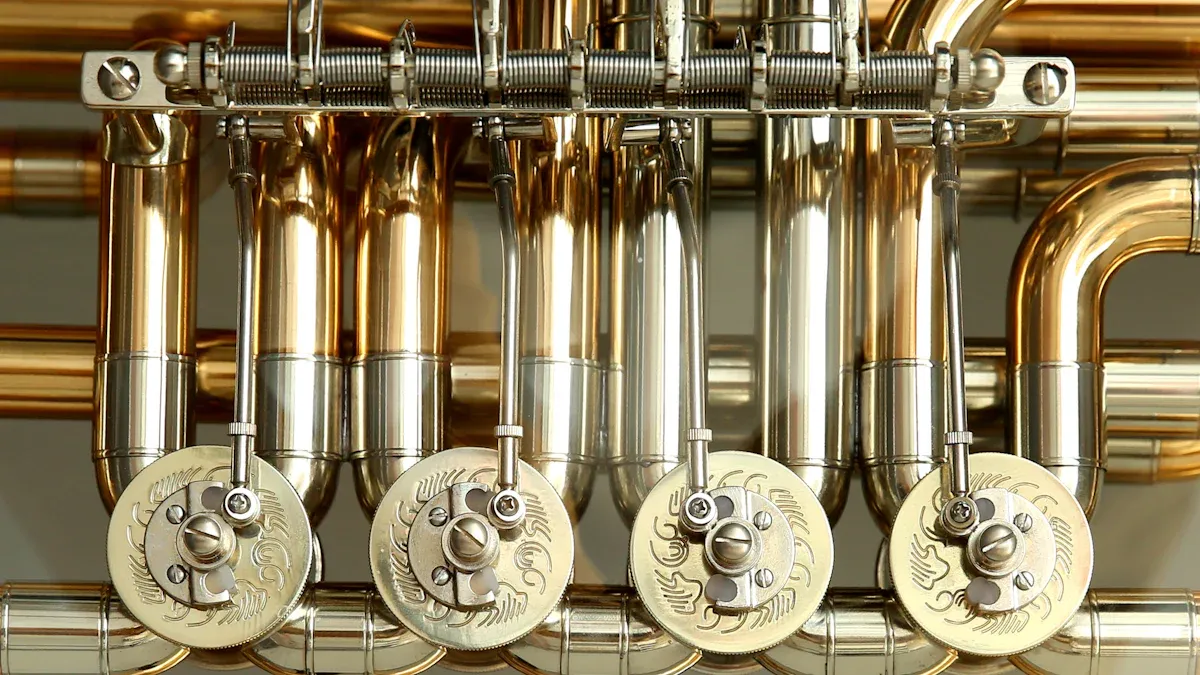

A ball valve is a type of quarter-turn valve that uses a spherical disc, known as a ball, to control the flow of fluid through it. The ball has a hole or port through its center, allowing fluid to pass when the valve is open. When the valve is closed, the ball rotates to block the flow. This design provides a reliable and efficient means of controlling fluid movement in various applications.

Key Components of a Ball Valve

The main components of a ball valve include:

| Component | Description |

|---|---|

| Valve Body | The main structural part that connects to the pipeline and withstands system pressure. |

| Ball | The core component controlling fluid flow, typically precision-machined and chrome-plated. |

| Seat | Forms the seal by contacting the ball, crucial for sealing performance. |

| Stem | Connects the actuator or handle to the ball, controlling its rotation. |

| Packing & Gasket | Prevents external leakage, with materials selected for compatibility with operating conditions. |

| Operating Device | Manual or automatic devices that allow for the opening and closing of the valve. |

Ball valves are commonly constructed from materials such as stainless steel, brass, PVC, bronze, and cast iron. Each material has unique characteristics that influence performance. For instance, stainless steel offers excellent corrosion resistance, making it ideal for food processing and chemical applications. Brass is cost-effective but less suitable for corrosive environments. PVC is lightweight and resistant to chemicals, though it cannot withstand high temperatures. Understanding these materials is crucial for selecting the right ball valve for specific applications.

Operational Principles

Ball valves operate on a simple principle. When the handle is turned, the ball rotates within the valve body. This rotation either aligns the port with the flow path, allowing fluid to pass, or turns the ball to block the flow entirely. The design ensures minimal pressure drop and allows for quick shut-off, making ball valves a popular choice in various industries.

Definition of Union Ball Valve

A union ball valve is a specialized type of ball valve that incorporates a union fitting, allowing for easy disassembly and reassembly. This design feature significantly enhances maintenance efficiency and simplifies installation processes. Unlike standard ball valves, which often require cutting pipes for replacement, union ball valves utilize union nuts that facilitate quick removal.

Unique Structural Features

The structural differences between a union ball valve and a standard ball valve are notable. The following table outlines these differences:

| Feature | Union Ball Valve | Standard Ball Valve |

|---|---|---|

| Installation | Uses union nuts for easy removal | Permanently installed, solvent-welded |

| Maintenance | Easily removable for service without cutting pipe | Requires cutting pipe for replacement |

| Design Purpose | Designed for future serviceability | Suitable for simple, non-critical lines |

The union mechanism in a union ball valve allows for straightforward maintenance tasks. Technicians can shut off the flow and unscrew the union nuts to remove components easily. This feature streamlines the process of valve replacement, making it efficient and less time-consuming.

Benefits of the Union Mechanism

The union mechanism provides several advantages:

- Easy Disassembly: The design allows for quick access to internal components without the need for specialized tools.

- Quick Access: Maintenance personnel can perform repairs or replacements swiftly, minimizing downtime.

- Efficient Maintenance: The straightforward nature of the union ball valve simplifies routine checks and servicing.

Key Differences Between Ball Valve and Union Ball Valve

Ball valves and union ball valves differ significantly in their design and functionality. Understanding these differences helps in selecting the right valve for specific applications.

- Operational Mechanism:

- Ball valves allow free movement of the ball, enabling quick flow control.

- In contrast, union ball valves secure the ball with a pin, which enhances stability during operation.

- Friction Levels:

- Standard ball valves experience higher friction due to their design.

- Union ball valves, however, reduce friction, promoting smoother operation.

- Maintenance and Removal:

- Removing a standard ball valve from a system requires disassembly, which can be time-consuming.

- Union ball valves simplify this process, allowing for easy removal without extensive disassembly.

- Pressure Handling:

- Both types handle standard pressure, but union ball valves excel in high-velocity systems. Their robust construction supports greater pressure variations.

The following table summarizes some of the key differences:

| Feature | Ball Valve | Union Ball Valve |

|---|---|---|

| Ball Movement | Free movement | Secured by a pin |

| Friction | Higher friction | Less friction due to design |

| Removal from System | Requires disassembly | Easily removable without disassembly |

| Pressure Handling | Standard pressure | Suitable for high velocity systems |

In terms of temperature ratings, both types perform similarly at lower temperatures. However, as temperatures rise, the integrity of standard ball valves may compromise significantly, while union ball valves maintain better performance under stress.

Overall, the union ball valve offers advantages in maintenance and operational efficiency, making it a preferred choice in many applications.

Advantages of Ball Valves

Ball valves offer numerous advantages that make them a preferred choice in fluid control systems. Their design and functionality contribute to efficiency and reliability in various applications. Here are some key benefits:

- Quick Operation: Ball valves feature a quarter-turn mechanism, allowing for rapid opening and closing. This capability is essential for immediate flow control in critical situations.

- Low Flow Resistance: Their streamlined design minimizes flow resistance. This characteristic ensures smooth fluid passage while maintaining system pressure.

- Durability and Lifespan: Constructed from robust materials, ball valves are built to withstand harsh conditions. They require minimal maintenance, contributing to their long lifespan.

- Reliable Sealing: Ball valves provide a dependable barrier against leakage. This feature is crucial when handling hazardous fluids, ensuring safety and compliance.

- Versatility: These valves are suitable for a wide range of applications, from residential plumbing to industrial processes. Their adaptability makes them a valuable asset in various settings.

- Easy Maintenance: The simple design of ball valves allows for straightforward maintenance procedures. Technicians can perform routine checks with minimal disruption to the system.

- Cost Effectiveness: Although ball valves may have a higher initial cost, their durability and low maintenance needs lead to long-term savings. This aspect makes them a wise investment for many operations.

- Compatibility with Automation: Ball valves can easily integrate with automated control systems. This compatibility enhances operational efficiency and allows for precise flow regulation.

Advantages of Union Ball Valves

Union ball valves offer several advantages that enhance their functionality in fluid control systems. Their unique design simplifies installation and maintenance, making them a preferred choice for many applications. Here are some key benefits:

- Easy Installation and Maintenance: The union design facilitates straightforward removal, inspection, and replacement. This feature significantly reduces the time and effort required for maintenance tasks.

- Low Maintenance Requirements: Once installed, these valves require minimal upkeep. Their robust construction ensures longevity and reliability, which is crucial in demanding environments.

In addition to these benefits, union ball valves provide operational flexibility in piping systems. The following table outlines some of their key features:

| Feature | Description |

|---|---|

| Modular Construction | Allows users to select from various end connections to fit different piping standards. |

| Easy Maintenance | Users can upgrade or change parts without needing to replace the entire valve. |

| Quick Disassembly and Reassembly | The true union design facilitates fast maintenance and operational adjustments. |

| High Flow Rate Performance | Maintains reliable performance in high-pressure or high-flow applications. |

These advantages make union ball valves an excellent choice for both residential and industrial applications. Their design not only enhances efficiency but also ensures that technicians can perform necessary maintenance quickly and effectively.

Disadvantages of Ball Valves

While ball valves offer numerous advantages, they also present certain disadvantages that users should consider. Understanding these drawbacks can help in making informed decisions regarding valve selection.

- Cavitation Risks in High-Pressure Systems: Ball valves can experience cavitation due to rapid pressure changes. This phenomenon leads to bubble formation and collapse, which erodes valve components and compromises performance.

- High Torque Requirements for Large Diameters: Larger ball valves require significantly more torque to operate. Factors such as size, pressure rating, and media properties influence this requirement. Manual operation becomes impractical, necessitating the use of actuators, which can increase costs.

The following table summarizes these disadvantages:

| Disadvantage | Description |

|---|---|

| Cavitation Risks in High-Pressure Systems | Cavitation can occur due to rapid pressure changes, leading to bubble formation and collapse, which erodes valve components and compromises performance. |

| High Torque Requirements for Large Diameters | Larger ball valves require significantly more torque to operate, influenced by size, pressure rating, and media properties, making manual operation impractical and necessitating actuators, which add to costs. |

Additionally, ball valves may struggle under conditions involving high particulate matter or abrasive fluids. While soft sealing ball valves can tolerate minor solid particles better than metal-seated options, they are not recommended for highly abrasive services. Eccentric half-ball valves, designed to minimize contact with the seat, are ideal for handling abrasive slurries and reducing wear.

Disadvantages of Union Ball Valves

While union ball valves offer several advantages, they also come with notable disadvantages. Understanding these drawbacks is essential for making informed decisions in fluid control applications.

- Environmental Concerns: The use of PVC in union ball valves raises environmental issues. PVC contributes to pollution and degradation due to plastic waste. This factor can deter environmentally conscious users from selecting these valves.

- Chemical Compatibility Issues: Union ball valves made from PVC may not be compatible with all chemicals. This incompatibility can lead to degradation and premature valve failure in specific environments. Users must carefully assess the chemicals involved in their applications.

- Cost Considerations: Union ball valves generally have higher manufacturing costs compared to standard ball valves. For instance, a union ball valve can cost around $585.15, while a standard ball valve may only cost $28.24. This price difference can make union ball valves less suitable for budget-sensitive projects.

- Temperature and Pressure Limits: PVC union ball valves have lower temperature and pressure ratings than their metal counterparts. This limitation restricts their use in high-temperature applications, where metal valves would perform better.

- Maintenance and Longevity: Regular maintenance is necessary for PVC union ball valves, especially in environments with fluctuating temperatures. Over time, exposure to UV light can cause these valves to become brittle or deteriorate, impacting their longevity.

The following table summarizes these disadvantages:

| Disadvantage | Description |

|---|---|

| Environmental Concerns | PVC contributes to pollution and degradation due to plastic waste. |

| Chemical Compatibility Issues | PVC may not be compatible with all chemicals, leading to degradation and premature valve failure. |

| Cost Considerations | Union ball valves typically have higher manufacturing costs, making them less suitable for budget-sensitive projects. |

| Temperature and Pressure Limits | PVC valves have lower temperature and pressure ratings than metal valves, limiting their use in high-temperature applications. |

| Maintenance and Longevity | Regular maintenance is required, as PVC valves can become brittle or deteriorate from UV exposure over time. |

Understanding these disadvantages helps users weigh the benefits against the potential drawbacks when selecting a union ball valve for their specific needs.

Typical Applications of Ball Valves

Ball valves find extensive use across various industries due to their reliability and efficiency. Their design allows for quick operation and minimal flow resistance, making them suitable for numerous applications. Here are some typical uses:

- Gas Applications: Ball valves are essential in piping systems for combustible fluids. They effectively control the flow of hydrocarbons, liquefied petroleum gas (LPG), and natural gases.

- Heating Systems: These valves play a crucial role in boilers and furnaces, where they regulate gas flow to ensure safe and efficient operation.

- Water Heating: In residential and commercial settings, ball valves are commonly found in water heaters. They help manage water flow, contributing to energy efficiency and safety.

- Industrial Processes: Many manufacturing processes utilize ball valves for controlling the flow of liquids and gases. Their durability makes them ideal for harsh environments.

Tip: When selecting a ball valve for specific applications, consider factors such as pressure ratings, temperature limits, and the type of fluid being handled. This ensures optimal performance and longevity.

Typical Applications of Union Ball Valves

Union ball valves find extensive use in various sectors due to their ease of maintenance and reliable performance. Their unique design allows for quick disassembly, making them ideal for applications where regular maintenance is necessary. Here are some common areas where union ball valves excel:

| Application Area | Description |

|---|---|

| Residential Plumbing | These valves serve as main water shutoffs and branch shutoffs during leaks. They are also used in devices like taps and showers. |

| Refrigeration Systems | Union ball valves function as shut-off valves in HVAC systems and air conditioners. They handle high-pressure refrigerants effectively. |

| Oil and Gas Industries | In production facilities and fuel gas systems, these valves control flow. They are designed for high-pressure applications, ensuring safety and efficiency. |

In chemical processing plants, union ball valves enhance maintenance efficiency through several key practices:

- Regular inspections help identify early signs of wear and damage, which is crucial for maintaining valve functionality.

- Cleaning of PVC ball valves prevents dirt and debris accumulation, ensuring optimal performance and reducing maintenance needs.

- Maintaining records of all maintenance activities aids in tracking valve conditions and supports compliance with safety regulations.

These features make union ball valves a preferred choice in both residential and industrial applications, ensuring reliable operation and ease of maintenance.

Choosing between a ball valve and a union ball valve requires careful consideration of several factors. Key aspects include valve design, servicing needs, and compatibility with the media used.

- Considerations:

- Valve design

- Operation type

- Body material

- Seal materials

- Specific application requirements

| Consideration | Standard Ball Valve | Union Ball Valve |

|---|---|---|

| Design | Basic design, typically less complex | More complex, allows for easy servicing |

| Servicing | May require complete removal for repair | Easy to service without removing the valve |

| Application | Suitable for many general applications | Ideal for applications needing frequent maintenance |

While union ball valves may have a higher initial cost, they often lead to lower long-term maintenance expenses due to their modular design. This design allows for individual component replacement, reducing downtime and enhancing cost-effectiveness in systems requiring frequent servicing.

FAQ

What is the primary function of a ball valve?

Ball valves control fluid flow by rotating a spherical disc to open or close the passage.

How does a union ball valve differ from a standard ball valve?

A union ball valve features a union fitting, allowing for easy disassembly without cutting pipes.

Are ball valves suitable for high-pressure applications?

Yes, ball valves can handle high-pressure applications, but union ball valves excel in high-velocity systems.