What is 3/4 pvc valve?

A 3/4 PVC valve serves as a crucial component in plumbing and irrigation systems. It effectively regulates water flow through 3/4 inch PVC pipes. This valve ensures efficient water management, making it essential for both residential and industrial applications. Understanding its role enhances overall system performance.

Key Takeaways

- A 3/4 PVC valve is essential for regulating water flow in plumbing and irrigation systems, ensuring efficient water management.

- Key features of a 3/4 PVC valve include leak resistance, corrosion resistance, and ease of installation, which enhance its reliability and performance.

- Regular maintenance, including inspections and cleaning, is crucial for extending the lifespan and ensuring the optimal operation of a 3/4 PVC valve.

Construction of a 3/4 PVC Valve

Materials Used

A 3/4 PVC valve primarily consists of several materials, each selected for its unique properties. The most common material is PVC (polyvinyl chloride), known for its lightweight and durable characteristics. Other materials include Buna N, Santoprene, and PTFE, which enhance the valve’s performance in various applications. The following table summarizes the properties of these materials:

| Material | Maximum Operating Pressure | Maximum Operating Temperature |

|---|---|---|

| PVC | 125 psi | 140°F |

| Buna N | N/A | N/A |

| Santoprene | N/A | N/A |

| PTFE | N/A | N/A |

Design Features

The design of a 3/4 PVC valve significantly contributes to its performance and reliability. Key features include leak resistance, corrosion resistance, and ease of installation. The following table outlines how these features enhance the valve’s functionality:

| Feature | Contribution to Performance and Reliability |

|---|---|

| Leak Resistance | Precision-engineered seals and smooth internal surfaces prevent fluid leakage, even under high pressure. |

| Corrosion Resistance | PVC valves maintain structural integrity in aggressive chemical environments, preventing leaks and failures. |

| Ease of Installation | Features like socket or solvent ends simplify the installation process, saving time and effort. |

These materials and design features work together to ensure that the 3/4 PVC valve operates efficiently in various plumbing and irrigation systems.

Functionality of a 3/4 PVC Valve

How It Operates

A 3/4 PVC valve operates by controlling the flow of water through a plumbing system. When the valve is opened, water flows freely through the pipe. Conversely, when closed, the valve restricts or stops the flow entirely. This operation is crucial for managing water supply in various applications, from irrigation systems to household plumbing.

The valve’s design allows for smooth operation, minimizing turbulence and pressure loss. The internal components, such as the ball or gate, move in response to user input, either manually or automatically. This responsiveness ensures that users can quickly adjust water flow as needed.

The typical working pressure for a 3/4 PVC valve is around 150 PSI, with a maximum temperature tolerance of 140 degrees Fahrenheit. These specifications make it suitable for a wide range of applications, ensuring reliable performance under varying conditions.

| Specification | Value |

|---|---|

| Working Pressure | 150 PSI |

| Maximum Temperature | 140 degrees F |

Types of Mechanisms

3/4 PVC valves utilize various mechanisms to control water flow. The most common types include:

- Ball Valves: These valves feature a spherical disc that rotates to open or close the flow. They provide excellent sealing capabilities and are ideal for applications requiring quick shut-off.

- Gate Valves: Gate valves use a sliding gate to control flow. They are best suited for applications where the valve remains either fully open or fully closed, as they do not regulate flow well in intermediate positions.

- Check Valves: These valves allow fluid to flow in one direction only, preventing backflow. They are essential in systems where reverse flow could cause damage or contamination.

- Globe Valves: Globe valves have a spherical body and are designed for regulating flow. They offer good throttling capabilities but may create more pressure drop compared to other types.

The choice of mechanism depends on the specific requirements of the plumbing system. Each type offers unique advantages, making it essential to select the right valve for optimal performance.

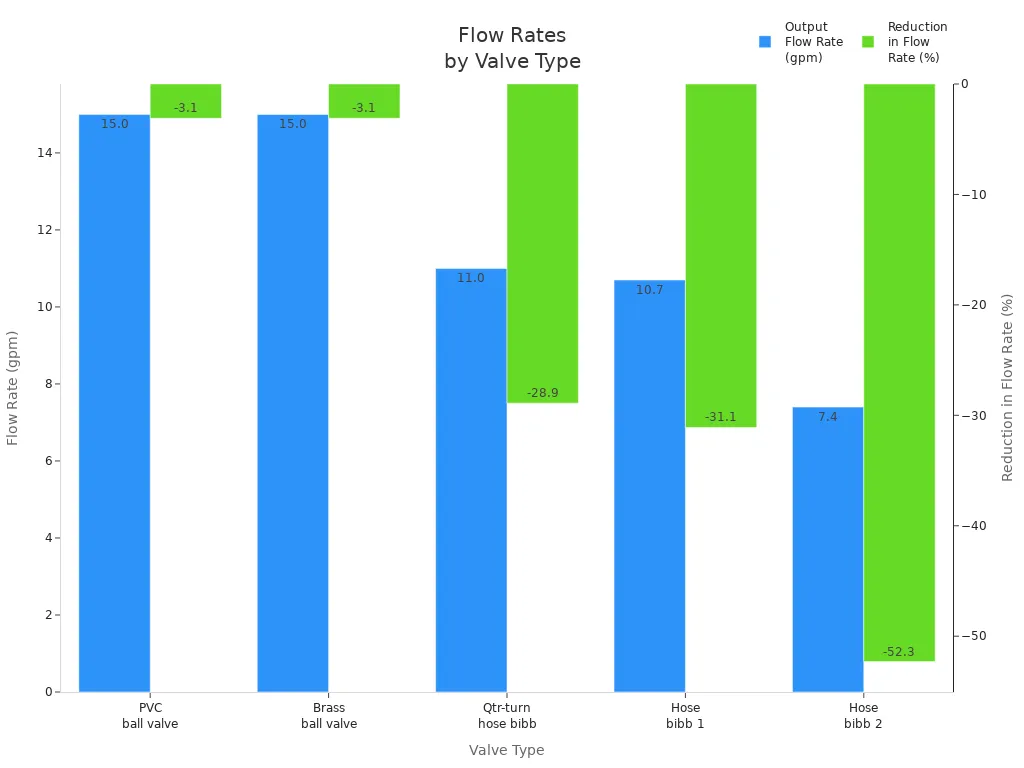

The chart above illustrates how flow rates through 3/4 PVC valves compare to other common valve sizes. Understanding these differences helps users make informed decisions when selecting valves for their systems.

Applications of a 3/4 PVC Valve

Residential Uses

In residential settings, 3/4 PVC valves play a vital role in various applications. Homeowners rely on these valves for efficient water management and system reliability. The following table outlines some common residential applications along with their benefits:

| Application | Benefits |

|---|---|

| Water main shut-offs | Quick-turn operation for emergency shut-off |

| Hot water heater connections | Reliable and durable for high-temperature use |

| Outdoor spigots | Easy access for garden and outdoor water use |

These applications highlight how a 3/4 PVC valve enhances convenience and safety in home plumbing systems. For instance, the quick-turn operation of a valve at the water main allows homeowners to swiftly shut off water during emergencies, preventing potential damage.

Industrial Uses

In industrial environments, 3/4 PVC valves contribute significantly to operational efficiency and safety. Industries utilize these valves in various systems, including irrigation, chemical processing, and water treatment. The use of 3/4 PVC valves in irrigation systems is particularly noteworthy. They facilitate efficient water distribution, which is essential for water conservation. Smaller pipe sizes can provide sufficient water flow for residential systems while minimizing water wastage through optimized system design.

Drip irrigation systems, which employ a network of valves and pipes, exemplify this efficiency. They deliver water directly to plant root zones, ensuring that only necessary areas receive irrigation. This targeted approach significantly reduces water usage, contributing to overall water conservation efforts in agricultural practices.

Advantages of a 3/4 PVC Valve

Cost-Effectiveness

One of the primary advantages of a 3/4 PVC valve is its cost-effectiveness. Compared to similar-sized valves made from other materials, PVC valves offer significant savings. For instance, a 3/4 PVC valve typically costs around $3.37, while metal and specialized plastic valves do not have a standard price available. This affordability makes PVC valves an attractive option for both residential and industrial applications.

| Valve Material | Size | Price |

|---|---|---|

| PVC | 3/4″ | $3.37 |

| Metal | 3/4″ | N/A |

| Specialized Plastic | 3/4″ | N/A |

Durability and Resistance

Durability is another key benefit of 3/4 PVC valves. These valves exhibit high resistance to chemical corrosion, making them suitable for various applications. PVC valves can withstand exposure to a wide range of chemicals, including acids, bases, and aggressive solvents. This resistance is crucial in industries such as chemical processing and water treatment.

- Plastic ball valves offer superior resistance to:

- Acids

- Bases

- Salts

- Aggressive solvents

Additionally, PVC valves maintain their integrity in harsh environments, unlike stainless steel valves, which may deteriorate when exposed to specific chemicals. This durability ensures long-term reliability and reduces the need for frequent replacements.

| Valve Material | Chemical Resistance | Applications |

|---|---|---|

| PVC | Highly resistant to chemical corrosion | Corrosive material control |

| Stainless Steel | Deteriorates with specific chemicals | Non-corrosive fluid management |

Maintenance Tips for 3/4 PVC Valves

Regular Inspection

Regular inspection of 3/4 PVC valves is essential for maintaining optimal performance. Users should check for common issues that may arise over time. These include:

- Mineral buildup or scaling

- Corrosion or chemical damage

- Loose connections

- Worn-out or damaged seals

Identifying these problems early can prevent more significant issues down the line. A thorough inspection should occur at least once a year, or more frequently in harsh environments.

Tip: Always ensure the system is depressurized before inspecting the valve to avoid accidents.

Cleaning and Repairs

Cleaning a 3/4 PVC valve involves removing any debris or buildup that may hinder its operation. Users should flush the valve with clean water and inspect the internal components for any signs of wear.

Repairing a valve typically involves a systematic approach. First, diagnose the issue. Next, disassemble the valve, replace or repair any damaged components, and then reassemble the valve to restore its functionality.

| Failure Mode | Description | Prevention Method |

|---|---|---|

| Reverse Flow | Water flows back from the outlet to the inlet, indicating a failure. | Regular maintenance and checks to ensure proper valve function. |

| Debris in Pipeline | Debris buildup can cause the valve to be stuck open or closed. | Regular cleaning and maintenance to prevent debris accumulation. |

| Water Hammer | Sudden changes in fluid flow can cause pressure surges damaging the valve. | Install water hammer arrestors and ensure proper system design to minimize surges. |

| Failing Seat Seal | Degradation of seals leads to fluid seepage and valve failure. | Regular inspection and replacement of seals as needed. |

| Inconsistent Fluid Flow | Disruptions in flow indicate a potential valve failure. | Monitor fluid flow and perform regular maintenance to ensure consistent operation. |

By following these maintenance tips, users can extend the life of their 3/4 PVC valves and ensure reliable operation.

A 3/4 PVC valve is vital in plumbing systems, offering reliable performance and ease of maintenance. Users benefit from understanding its construction and functionality. Key features include good sealing performance, corrosion resistance, and easy installation. These factors contribute to informed purchasing decisions, ensuring optimal fluid control in various applications.

| Feature | Description |

|---|---|

| Material | PVC |

| Size | 3/4″ |

| End connections | Solvent weld end connections, FMPT |

| Valve Type | Ball Valve |

| Certifications | NSF61 & NSF372 |

| Working Pressure | 150 PSI |

| Maximum Temperature | 140 degrees F |

FAQ

What is the lifespan of a 3/4 PVC valve?

A 3/4 PVC valve typically lasts 10 to 20 years, depending on usage and environmental conditions.

Can I use a 3/4 PVC valve for hot water applications?

Yes, a 3/4 PVC valve can handle hot water applications up to 140 degrees Fahrenheit.

How do I know if my 3/4 PVC valve needs replacement?

Signs include leaks, difficulty opening or closing, and visible wear on seals or components. Regular inspections help identify these issues early.