What are common problems with PVC ball valves?

PVC ball valves often experience various issues. These include material degradation, operational failures, and problems related to installation. Such difficulties frequently cause leaks, diminish functionality, or lead to complete valve failure. Understanding these common challenges is crucial for effective system maintenance.

Key Takeaways

- PVC ball valves face problems from sunlight, chemicals, and extreme temperatures. These issues make the valves weak or cause them to break.

- Parts inside the valve, like seals and the stem, can wear out or break. This happens from frequent use, wrong installation, or dirt getting stuck inside.

- Installing PVC ball valves correctly is important. Too much force or not enough support can cause leaks and damage the valve over time.

Material Degradation and Environmental Factors Affecting PVC Ball Valves

UV Exposure and Brittleness in PVC Ball Valves

PVC materials degrade when exposed to ultraviolet (UV) light. Extended exposure to ultra-violet light causes oxidation, leading to discoloration and embrittlement. This process makes the material brittle and prone to failure. Valves connected to a UV sterilizer often experience stress cracking due to increased exposure. Such degradation compromises the structural integrity of the valve, reducing its lifespan and reliability.

Chemical Incompatibility with PVC Ball Valves

Certain chemicals react negatively with PVC, leading to material breakdown. Moderately polar solvents, such as tetrahydrofuran, can corrode PVC. Solvents that soften CPVC, including ethers, ketones, alcohols, esters, and aromatics, can lead to structural damage. Furthermore, concentrated organic solvents, for instance, acetone and toluene, are known to weaken PVC. Exposure to these substances causes softening, cracking, or complete failure of the valve.

Temperature Extremes and PVC Ball Valves

Temperature significantly affects PVC performance. The maximum temperature for PVC ball valves is 140°F (60°C). Most PVC ball valves can handle hot water up to 140°F (60°C) at full pressure rating. For continuous service, manufacturers typically rate these valves up to 140°F (60°C). Some manufacturers specify ranges from 120°F to 150°F for maximum continuous service. Typical maximum temperatures fall between 120-140°F. Most PVC valves are rated at 73°F and require derating above 100°F. High temperatures cause the material to soften and lose pressure resistance. Conversely, very low temperatures make PVC brittle, increasing the risk of cracking and leaks.

Operational and Mechanical Failures of PVC Ball Valves

Operational and mechanical issues frequently compromise the performance of PVC ball valves. These problems often stem from internal component wear, material fatigue, or external forces during use. Understanding these failure modes helps in selecting and maintaining valves effectively.

Seal and O-Ring Wear in PVC Ball Valves

Seals and O-rings are critical components in PVC ball valves; they prevent leaks and ensure proper flow control. Common materials for these seals include EPDM, FPM (Viton), and PTFE. However, these components experience wear over time, leading to operational failures. Frequent operation causes wear on internal parts like the ball and seals. High-frequency usage accelerates this wear, leading to premature failure of sealing surfaces. Improper installation also contributes significantly to premature wear. Misaligned ball valves create uneven pressure on seals. Over-torquing during installation compresses seals beyond their limits, reducing elasticity and causing leaks.

High temperatures also degrade sealing materials. Continuous operation at elevated temperatures causes O-rings, PTFE gaskets, and other elastomers to lose elasticity, become brittle, or even melt. This results in leaks. Chemical exposure further exacerbates wear. Certain chemicals, such as solvents, aromatics, chlorinated organic compounds, sodium hydroxide, and potassium hydroxide, are incompatible with PVC. These substances cause rapid degradation, leading to softening, cracking, or complete valve failure. Abrasive media, containing suspended solids or particles like sand, also wear down the valve’s seals and ball, causing premature failure. Worn or damaged seals, gaskets, or O-rings deteriorate over time, leading to leakage or a failure to seal properly.

Stem Breakage or Stripping in PVC Ball Valves

The valve stem connects the handle to the ball, allowing users to open or close the valve. Several issues can lead to stem failure. Deformation of the valve stem can cause the ball to rotate inflexibly. External impact, incorrect installation, or prolonged application of excessive torque often cause such deformation. Packing failure also contributes to stem-related problems. The packing material seals the stem, but it degrades over time due to high temperature, pressure, or chemical exposure. High temperatures dry out the packing, causing it to lose elasticity. Chemicals break down its structure. Improper installation or maintenance, such as insufficient compression, also creates gaps and leakage.

Stem damage itself is another common failure mechanism. Excessive force or torque during operation can bend or break the stem. A damaged stem cannot maintain a proper seal with the packing, resulting in leakage. Scratches or scores on the stem also compromise the packing’s sealing ability.

Ball Seizing or Sticking in PVC Ball Valves

The ball inside the valve can seize or stick, preventing proper operation. Several factors contribute to this problem. Misalignment or wear of internal components often causes seizing. Frequent operation, improper installation, or manufacturing defects lead to misalignment, accelerating wear and impairing rotation or sealing. Environmental conditions also play a role. Exposure to extreme temperatures, such as freezing that causes condensation to freeze, or high heat that warps components, increases the risk of sticking. Direct sunlight or corrosive chemicals also weaken materials. Low-quality materials are more prone to corrosion, wear, or failure under pressure.

Overuse or incorrect use of the valve beyond its intended application causes damage and premature wear. Corrosion and rust build-up on metal components, due to moisture and air, especially in outdoor or humid conditions, cause moving parts to bind. Hard water deposits and mineral accumulation, such as calcium and magnesium, form scale deposits that restrict the ball’s rotation. Debris or sediment, like sand or small rocks from the water line, can get stuck in the valve. A lack of regular valve maintenance, including neglecting cleaning, lubrication, and inspection, allows dirt, debris, and friction to build up. Seals and gaskets also degrade without proper care. New valve stiffness, where factory-fresh PTFE seats are tight against the ball, can also cause initial sticking. Infrequent use, leaving the valve open or closed for years, causes the seals to stick.

Handle Breakage on PVC Ball Valves

The handle is the primary interface for operating a ball valve, and its failure renders the valve inoperable. Handles on older, more common styles of PVC ball valves are particularly prone to cracking easily. This frequent failure often occurs at the handle itself. Manufacturers commonly use molded blue ABS for handles. Stainless steel is another material used for handles, offering greater durability. However, even with robust materials, excessive force or material fatigue can lead to breakage, especially if the valve ball is seized or stiff.

Installation and Application-Related Issues with PVC Ball Valves

Installation and application-related issues significantly impact the performance and longevity of ball valves. Incorrect installation practices or using valves outside their intended application parameters often lead to premature failure, leaks, and operational inefficiencies.

Over-tightening During Installation of PVC Ball Valves

Applying excessive force during installation presents a common problem for PVC ball valves. Over-tightening connections, for example, can cause cracks in the PVC material. This damage may not appear immediately but leads to long-term operational issues. Excessive force can also distort the valve body, compromising its structural integrity. These installation errors accelerate aging and affect the valve’s overall lifespan.

Improper Support and Stress on PVC Ball Valves

Inadequate support during installation causes significant stress on ball valves. A poorly supported valve can shift over time. This shifting, combined with vibration and pressure fluctuations, often results in leaks. Improper installation practices place additional stress on valve components, accelerating wear and potentially causing permanent damage. Leaks frequently appear near connection points. A poorly installed valve might feel loose or unstable, lacking the necessary support to maintain stability under pressure.

For thermoplastic valves, including PVC, failing to adequately support the piping system can lead to sagging. This sagging places excessive strain on the valve, especially during thermal expansion and contraction cycles. Proper bracing and support are crucial, particularly for larger or heavier piping systems. This prevents bending or twisting forces on the valve during operation, which could otherwise lead to premature wear or failure. Inadequate support can also lead to stress cracking in PVC fittings. Regular verification of pipe supports is recommended as part of preventive maintenance. This ensures they remain secure and properly spaced.

To prevent these issues, installers must ensure proper alignment of CPVC ball valves with the piping system. This prevents stress on the valve seat and stem, which can lead to leakage, reduced flow control, or valve failure. Always ensure the valve is correctly positioned and pipes are aligned and supported before tightening fittings. Use correct tools and techniques for a secure and leak-free connection. Cut pipes to required lengths using a fine-toothed saw or pipe cutter, ensuring smooth, burr-free edges to avoid damaging the valve seal. Deburr and chamfer pipe edges to remove sharp areas and prevent damage during installation, ensuring a tighter fit. Use appropriate CPVC primer and solvent cement, applying primer to both pipe and valve connection surfaces, then applying cement and inserting the pipe into the valve socket with a slight twist for a secure bond. Depressurize the piping system before installation to avoid accidental release of fluids or gases. Perform a pressure test after installation to check for leaks, inspecting all connections and the valve. Install the valve in an accessible location, ensuring the handle has enough space to turn freely. Avoid misalignment during installation to prevent unnecessary stress on the valve and extend its service life. Test the system under pressure before full operation to confirm correct installation and leak-free performance. Do not expose PVC to temperatures beyond its design limits, as excessive heat can weaken the valve. In colder climates, insulate to prevent freezing water from cracking the valve body.

Pressure Limitations of PVC Ball Valves

PVC and CPVC valves generally have lower pressure ratings compared to metallic valves. Manufacturers typically use them in lower-pressure, non-corrosive applications. Understanding these limitations is critical for safe and effective operation.

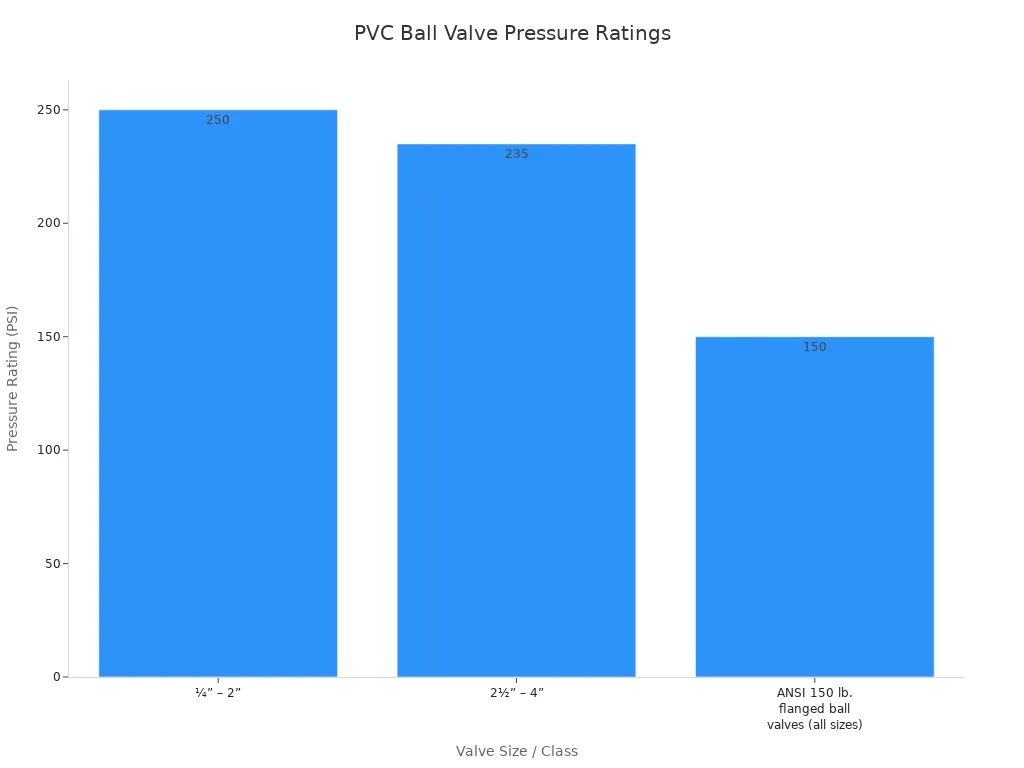

Here are typical pressure ratings for various PVC ball valve sizes at 70°F:

| Valve Size | Pressure Rating @ 70°F |

|---|---|

| ½” – 2” | 200 PSI |

| 2½” – 4” | 150 PSI |

For non-shock applications, some valves offer higher ratings:

| Valve Size | Pressure Rating @ 70°F (non-shock) |

|---|---|

| ¼” – 2” | 250 PSI |

| 2½” – 4” | 235 PSI |

| ANSI 150 lb. flanged ball valves (all sizes) | 150 PSI |

Operating PVC ball valves above their rated pressure limits poses significant risks. The most dangerous failure mode is catastrophic brittle failure. This occurs suddenly with little to no warning. It results in explosive fragmentation, sending sharp plastic shrapnel in all directions, and instantaneously releasing the full volume of compressed air. Even below thermal limits, PVC accumulates damage from pressure cycling, system vibration, chemical exposure (e.g., compressor oils), and UV degradation. These factors accelerate microscopic crack formation, reducing the valve’s effective pressure rating over time. Before catastrophic failure, PVC valves often show progressive deformation. This leads to seat leakage, system inefficiency, increased actuation torque, difficult operation, internal component binding, and system contamination as the valve material degrades.

The type of fluid also affects failure modes. Water is non-compressible. If a PVC pipe holding water cracks, the pressure drops instantly, resulting in a simple leak or split. The energy dissipates quickly and safely. However, gas is highly compressible and stores significant potential energy. If a PVC pipe holding compressed air fails, all that stored energy is released at once, causing a violent explosion. The pipe shatters rather than just cracking, leading to catastrophic failure. It is extremely dangerous to use standard PVC ball valves or pipes for compressed air or any other gas. The maximum recommended air pressure for PVC is zero. Pressurized gas stores tremendous energy. If the PVC fails, it can shatter into sharp, dangerous projectiles, leading to an explosion rather than just a leak.

Debris and Clogging in PVC Ball Valves

Debris and foreign particles commonly cause clogging and operational problems in ball valves. These include:

- Dirt buildup within the valve

- Debris buildup within the valve

- Buildup from water systems

- Buildup from irrigation systems

Such accumulations obstruct the ball’s movement, prevent proper sealing, and reduce flow efficiency.

Several preventative measures can minimize debris accumulation. Regular cleaning helps maintain functionality by removing dirt, debris, or chemical residues that can affect performance. This involves shutting off fluid flow, relieving pressure, and wiping the exterior with a soft cloth and warm, soapy water. For stubborn residues, a mild detergent can be used. If disassembly is possible, internal components should be cleaned with a soft cloth or brush to remove deposits obstructing the ball’s movement. Clean valves last longer by preventing debris buildup that negatively impacts performance. Use cleaning agents compatible with valve materials; alcohol- or water-based cleaners are ideal for non-metal parts. Clean at least annually, or more frequently in dirty or dusty environments.

Proper installation is fundamental for successful maintenance. Ensure valves fit correctly without misalignment or tension. Follow manufacturer guidelines for fittings and adhesive, ensuring connections are tight but not overtightened to prevent damage. Correctly installed ball valves are less likely to require repairs or replacement. Ensure the installing engineer has relevant experience and knowledge.

Lubrication is crucial for smooth operation. Apply a silicone-based lubricant or similar product designed for plastic applications to the handle and shaft where it connects to the valve body. Avoid petroleum-based lubricants, which can degrade PVC. Apply sparingly to prevent excess buildup that attracts dirt and debris. Lubrication ensures smooth operation, prevents abrasion, and enhances seal effectiveness. Use synthetic, water-insoluble, oil-based lubricants, avoiding clay- or solid-based types that can build up. Select a lubricant compatible with valve materials and system media.

Recognizing common problems with PVC ball valves, including material degradation, operational failures, and installation issues, is essential for effective selection. Proper installation and ongoing maintenance are crucial. These actions mitigate problems and ensure reliable performance and longevity of PVC ball valves. Proactively addressing challenges prevents leaks, operational disruptions, and premature replacement.

FAQ

Why do PVC ball valves become brittle?

UV light exposure causes PVC to oxidize, leading to discoloration and brittleness. Extreme cold temperatures also make the material brittle, increasing the risk of cracking.

What causes PVC ball valve leaks?

Leaks often result from worn seals or O-rings. Improper installation, such as over-tightening or inadequate support, also creates stress points that lead to leaks.

Can PVC ball valves handle hot water?

PVC ball valves typically handle hot water up to 140°F (60°C). Exceeding this temperature softens the material, reducing its pressure resistance and potentially causing failure.