Unlock Higher Profits in 2026 Source PPR Pipes Directly from a Ningbo Manufacturer

Maximize profit margins by sourcing PPR Pipes directly. Choosing the right PPR pipe supplier offers a strategic advantage. Direct sourcing is your key to profitability in 2026. The global PPR pipe market shows significant growth.

| Metric | Value |

|---|---|

| Market Size (2026) | US$ 10378.93 Million |

| Market Size (2035) | US$ 21983.52 Million |

| CAGR (2026-2035) | 8.7% |

This growth highlights the immense opportunity. A direct PPR pipe supplier Ningbo empowers businesses. They secure better deals and control quality. This includes a wide range of products, even a CPVC FITTING.

Key Takeaways

- Direct sourcing PPR pipes from a manufacturer saves money. It removes extra costs from trading companies.

- Manufacturers offer better quality control. They manage production from start to finish.

- Ningbo is a good place to find PPR pipe manufacturers. It has strong factories and good technology.

- Check for factory photos and certifications. This helps you find a real manufacturer, not a trading company.

- Direct partnerships help businesses grow. They lead to new ideas and faster problem solving.

Manufacturer vs. Trading Company: Understanding the Core Differences

Businesses often face a critical choice when sourcing PPR pipes: partner with a manufacturer or a trading company. Understanding their fundamental differences empowers better decision-making and directly impacts profitability.

Defining a PPR Pipe Manufacturer

A PPR pipe manufacturer directly produces the pipes and fittings. They own the factories, machinery, and production lines. Manufacturers invest heavily in research and development, ensuring product innovation and consistent quality. For example, a leading manufacturer like Donsen, established in 1996, possesses over two decades of experience. They specialize in plastic pipelines for water supply and irrigation systems. Their product range includes PP-R pipes and fittings, C-PVC pipes and fittings, PE pipes and fittings, and various plastic valves. They utilize imported high-quality raw materials and advanced production lines, such as fiberglass and PPR brass composite lines. This direct control over the entire production process guarantees adherence to strict quality standards and allows for comprehensive product system development.

Understanding a PPR Pipe Trading Company

A PPR pipe trading company acts as an intermediary. They do not own manufacturing facilities. Instead, trading companies source products from various manufacturers and then resell them to buyers. Their primary role involves facilitating transactions, managing logistics, and often consolidating orders from multiple suppliers. They typically focus on sales and distribution, offering a broader range of products from different factories. However, they lack direct control over the manufacturing process or the raw materials used.

Key Operational Distinctions

The operational differences between these two entities significantly affect a buyer’s experience and bottom line.

- Production Control: Manufacturers maintain complete control over production, from raw material selection to final product inspection. Trading companies rely on their suppliers’ quality control.

- Pricing Structure: Manufacturers offer direct factory pricing, eliminating intermediary markups. Trading companies add their profit margin, increasing the final cost.

- Product Expertise: Manufacturers possess deep technical knowledge about their products and production processes. Trading companies often have general product knowledge across various suppliers.

- Customization: Manufacturers can readily accommodate specific customization requests for products. Trading companies have limited ability to influence product specifications.

- Certifications: Manufacturers directly hold international certifications like CE, NSF, SABS, GOST, WRAS, and SKZ, validating their product quality. Trading companies typically rely on their suppliers’ certifications.

Choosing a direct manufacturer provides unparalleled advantages in quality, cost, and long-term partnership.

The Profit Advantage of Direct Sourcing from a PPR Pipe Supplier Ningbo

Businesses gain significant advantages when they choose to source PPR pipes directly from a manufacturer. This strategic decision directly impacts their bottom line and operational efficiency.

Significant Cost Savings

Direct sourcing from a PPR pipe manufacturer eliminates the intermediary markups that trading companies add. Trading companies purchase products from manufacturers and then resell them, adding their own profit margin to the cost. By bypassing this extra layer, businesses secure products at factory-direct prices. This direct transaction significantly reduces the overall procurement cost for PPR pipes and fittings. These savings directly translate into higher profit margins for the buyer, making their products more competitive in the market.

Uncompromised Quality Control

Manufacturers maintain complete control over the production process, ensuring consistent quality. They oversee every stage, from selecting raw materials to final product inspection. This direct oversight guarantees adherence to strict quality standards. For instance, manufacturers like Donsen use imported high-quality raw materials and advanced production lines. They also hold international certifications such as CE, NSF, SABS, GOST, WRAS, and SKZ. These certifications validate their product quality and compliance with global standards. Direct manufacturers generally offer superior quality control, more customization options, and greater transparency regarding raw material sourcing. This is often evidenced by in-house production facilities, machinery ownership, and dedicated engineering teams. Buyers can trust the quality of products when they come directly from the source.

Enhanced Communication and Transparency

Direct communication with a manufacturer streamlines the entire sourcing process. Buyers interact directly with the production team and technical experts. This direct line of communication leads to faster problem resolution and clearer understanding of product specifications. Communication efficiency and technical support are crucial factors that significantly influence the overall partnership experience when sourcing PPR pipes.

Manufacturers often provide quicker response times compared to trading companies. The fastest response times (typically ≤2 hours) are strongly associated with suppliers that have dedicated export departments and multilingual support teams. These teams are critical for minimizing delays in negotiations and order fulfillment.

Consider the average response times from various suppliers:

| Supplier Name | Avg. Response Time |

|---|---|

| Shanghai Zhongsu Pipe Co., Ltd. | ≤2h |

| Shanghai Ruihe Enterprise Group | ≤2h |

| Zhejiang Universal Fenghe Plastic | ≤1h |

| Zhejiang Xinniu Pipe Co., Ltd. | ≤8h |

| Weifang Palconn Plastics | ≤9h |

| Zhuji Fengfan Piping Co., Ltd. (A) | ≤1h |

| Shandong Amazon Pipe Co., Ltd. | ≤2h |

| Zhuji Fengfan Piping Co., Ltd. (B) | ≤2h |

| Zhuji Fengfan Piping Co., Ltd. (C) | ≤2h |

| Shanghai Pilsa Pipe Industry | ≤2h |

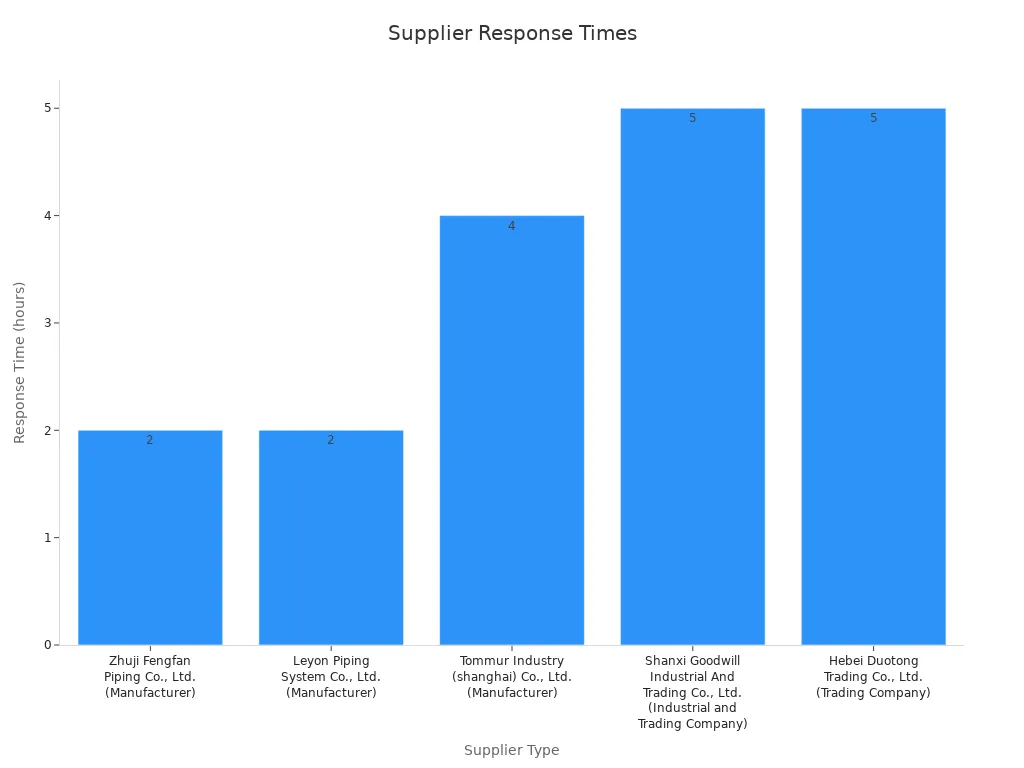

This chart further illustrates the difference in response times between manufacturers and trading companies:

Direct manufacturers like Zhuji Fengfan Piping Co., Ltd. and Leyon Piping System Co., Ltd. consistently show faster response times. This transparency extends to raw material sourcing and production schedules, giving buyers a complete picture of their order’s journey. Partnering with a direct PPR pipe supplier Ningbo ensures clear, efficient, and reliable communication.

Greater Customization Opportunities

Direct sourcing from a manufacturer unlocks significant customization opportunities. Trading companies often offer standard products. They have limited ability to alter specifications. Manufacturers, however, control the entire production line. This allows them to tailor products to specific project needs. Businesses gain a competitive edge with these custom solutions.

Manufacturers can adjust various product attributes. They offer flexibility in:

- Length

- Pressure rating

- Color coding

This means a business can order PPR pipes cut to precise lengths. This reduces waste and installation time on site. They can also specify different pressure ratings. This ensures the pipes meet the exact demands of a particular application. Color coding helps with easy identification of different pipe systems. For example, a specific color might indicate hot water lines. Another color could denote cold water lines. This level of detail is crucial for complex plumbing or irrigation projects.

A direct PPR pipe supplier Ningbo works closely with clients. They understand unique requirements. This collaboration leads to products perfectly suited for specific markets or projects. This direct relationship fosters innovation. It allows for the development of new solutions. This is a key advantage over relying on a trading company. Trading companies simply resell existing products. They cannot offer this level of tailored service. Choosing a direct manufacturer ensures products align perfectly with project specifications. This maximizes efficiency and client satisfaction.

Why Ningbo Excels as a PPR Pipe Manufacturing Hub

Ningbo stands out as a premier location for PPR pipe manufacturing. This city offers unique advantages that benefit international buyers. Its strategic position and industrial strength make it an ideal sourcing destination.

Ningbo’s Robust Manufacturing Ecosystem

Ningbo boasts a powerful manufacturing ecosystem. This environment strongly supports PPR pipe production. The region is a hub for precision engineering. It also leads in plastic processing equipment. Top-tier engineers are attracted to this area. Manufacturers here adhere to strict international standards. These include ISO 9001 and CE certification. These certifications are crucial for ensuring the quality and reliability of PPR pipes. For example, Ningbo Amico Plastic Industry Inc. specializes in pipes and fittings, including PP-R pipes. This company has an annual productivity exceeding 10,000 tons. It holds ISO9001 and ISO14001 certifications. Its PP-R pipes are recognized as a ‘Chinese best seller brand’. Ningbo Sunplast Pipe Co. Ltd. is another key player. It offers various PPR pipe products and services globally.

Access to Advanced Production Technologies

Manufacturers in Ningbo consistently access advanced production technologies. The city’s focus on innovation drives this. Companies invest in state-of-the-art machinery. They also adopt modern manufacturing processes. This commitment to technology ensures high-quality and efficient production. It allows for the creation of durable and reliable PPR pipes. This technological edge helps manufacturers meet diverse market demands.

Competitive Pricing from Ningbo Manufacturers

Ningbo manufacturers offer highly competitive pricing for PPR pipes. The city’s status as a major port plays a significant role. This logistical advantage benefits companies in Zhejiang and Shanghai. They enjoy competitive freight rates. They also receive reliable documentation support. This reduces overall shipping costs. These savings are passed on to buyers. This makes a PPR pipe supplier Ningbo an economically attractive choice. Businesses can achieve greater profitability by sourcing directly from this region.

Identifying a Genuine PPR Pipe Supplier Ningbo

Securing a reliable PPR pipe supplier Ningbo requires careful discernment. Buyers must distinguish between genuine manufacturers and trading companies. This distinction is crucial for long-term success and product quality.

Red Flags for Trading Companies

Several indicators suggest a supplier might be a trading company rather than a direct manufacturer. A lack of factory photos or videos is a significant red flag. Genuine manufacturers readily provide extensive visual documentation of their production facilities and machinery. Trading companies often lack these or show generic images. Another sign is a limited product range. Manufacturers typically specialize in specific products or materials. A supplier offering an extremely broad catalog across unrelated industries is more likely a trading company. Inconsistent branding or packaging also points to a trading company. Manufacturers maintain consistent branding. Trading companies might supply products with varying branding from different sources. Furthermore, trading companies often lack R&D or technical support. Direct manufacturers invest in research and development and offer in-depth technical support. Trading companies have limited technical knowledge. They also might have unusually high Minimum Order Quantities (MOQ) for smaller orders. This happens because they consolidate orders from various smaller manufacturers. Finally, trading companies are often reluctant to arrange factory visits. A direct manufacturer welcomes factory visits to showcase operations and quality control.

Verifying Manufacturing Capabilities

Buyers must verify a supplier’s manufacturing capabilities. Request specific documentation and certifications. This includes material certifications against standards like ASME B31.3, ISO 10380, or applicable national standards. Manufacturers should provide documentation explicitly stating approvals for specific applications. Test reports are also essential. Look for manufacturer technical specifications detailing approved applications. Product markings and material certifications referencing relevant standards, such as water-specific standards for PPR, confirm compliance. Additionally, request detailed documentation regarding chemical resistance and thermal properties. This documentation confirms compliance with industry standards.

The Importance of Factory Audits

Conducting a factory audit is a critical step. It ensures the supplier meets quality and production standards.

Tip: A thorough factory audit includes several key areas.

- Raw Material Inspection: Test each batch of PPR resin and additives for physical and chemical properties. This includes melt flow rate, density, and thermal stability.

- In-line Quality Checks: Continuously monitor diameter, wall thickness, and surface finish during extrusion. Inspect dimensions and appearance during injection molding.

- Final Product Testing: Conduct hydrostatic pressure tests, impact resistance tests, and long-term aging tests.

- International Certifications: Verify certifications like NSF, KTW, and WRAS. These require adherence to strict guidelines for material safety and product performance.

Audits also involve pressure and hydrostatic testing. This identifies leaks or weaknesses under high internal pressures. Thermal stability and heat aging tests evaluate material stability at elevated temperatures. Impact and mechanical strength testing assess toughness and flexibility. Chemical resistance testing ensures fittings remain unaffected by corrosion. Fusion and joint integrity tests confirm leak-proof connections. Manufacturers should also implement batch traceability and Statistical Quality Control (SQC). This maintains consistency and allows quick identification of defective products. Compliance with international standards like ISO 15874 and DIN 8078 is vital. Many manufacturers use automated and Non-Destructive Testing (NDT) technologies. This includes ultrasonic testing for internal inconsistencies.

Long-Term Benefits of Partnering with a Direct PPR Pipe Supplier Ningbo

Building Strategic Partnerships

Partnering directly with a manufacturer fosters strong, lasting relationships. Businesses develop trust and mutual understanding. This direct connection goes beyond simple transactions. It creates a foundation for sustained growth and collaboration. A direct PPR pipe supplier Ningbo becomes a reliable ally. They understand specific business needs and market demands. This deep understanding allows for tailored solutions and consistent support. These strategic alliances provide stability and predictability in the supply chain.

Faster Problem Resolution

Direct communication with a manufacturer significantly speeds up problem resolution. When issues arise, buyers speak directly to the source. This eliminates delays caused by intermediaries. Manufacturers possess the technical expertise to quickly diagnose and solve problems. They can implement solutions efficiently. This direct line ensures that production adjustments or quality concerns receive immediate attention. Quick resolution minimizes disruptions and maintains project timelines. It also builds confidence in the supplier’s commitment to customer satisfaction.

Innovation and Product Development Collaboration

Direct partnerships open doors for significant innovation and product development. Manufacturers actively pursue product innovation and differentiation. They develop eco-friendly, smart, and customizable piping solutions. This meets evolving customer demands and regulatory standards. Collaborating directly allows businesses to integrate smart solutions. They can embed sensors and IoT-enabled features into piping systems. This enhances monitoring, maintenance, and lifecycle management. It creates value-added offerings.

Manufacturers also focus on product differentiation through sustainability. They develop biodegradable or bio-based PPR pipes. This aligns with global sustainability trends and regulatory shifts. It offers a competitive advantage. Leading equipment manufacturers and technology providers drive continuous enhancements. They prioritize research and development investments. They also forge strategic partnerships with materials suppliers. This co-develops specialized polymer blends. These optimize melt flow characteristics and joint strength. This delivers differentiated performance for specific application segments. Collaborative ecosystems between pipe producers, raw material suppliers, and machinery vendors foster co-development efforts. This accelerates time to market for new product variants.

When a Trading Company Might Be Considered for PPR Pipes

Direct sourcing from a manufacturer offers many benefits. However, specific situations make a trading company a practical choice for PPR pipes. Businesses should understand these scenarios. They can then make informed decisions.

Niche Sourcing Requirements

Sometimes, a project requires very specific or unusual PPR pipe products. A single manufacturer might not produce all these items. Trading companies often have extensive networks. They can source diverse products from various factories. This makes them useful for niche requirements. They can find specialized fittings or unique pipe dimensions. This saves buyers time and effort. Buyers avoid contacting multiple manufacturers themselves.

Small Order Volumes

Startups or businesses testing new markets often need smaller quantities of PPR pipes. Large manufacturers typically have high Minimum Order Quantities (MOQ). This makes small orders difficult or expensive. Trading companies are more flexible with order sizes.

| Supplier Type | Typical MOQ (pieces) | Unit Price (example) | Notes |

|---|---|---|---|

| Large Manufacturers | 3,000–5,000 | $0.18 (for 5,000 pcs) | Lower unit price, higher MOQ |

| Trading Companies | As low as 1,000 | $0.25 (for 1,000 pcs) | Higher unit price, lower MOQ, suitable for startups/testing |

Trading companies are suitable for smaller orders. Their MOQs can be as low as 1,000 pieces. This benefits startups or businesses testing new markets. Large manufacturers typically require MOQs ranging from 3,000 to 5,000 pieces for standard items. Therefore, trading companies provide a viable option for smaller-scale procurement.

Consolidated Sourcing Needs

Some buyers need a wide range of products beyond just PPR pipes. They might require other plumbing materials or construction supplies. A trading company can consolidate these diverse sourcing needs. They manage multiple suppliers. This simplifies the procurement process for the buyer. Buyers receive a single invoice and shipment. This reduces administrative work. It also streamlines logistics. This approach is efficient for businesses with varied material requirements.

Maximizing Your 2026 Profit: The Strategic Choice for PPR Pipes

Businesses aiming for peak profitability in 2026 must make strategic choices. Sourcing PPR pipes directly from a manufacturer represents one of the most impactful decisions. This approach secures significant advantages over traditional methods. It positions companies for sustained success and market leadership.

Direct Sourcing for Optimal ROI

Direct sourcing directly impacts a company’s return on investment (ROI). Eliminating intermediaries means businesses pay factory-direct prices. This immediately boosts profit margins on every unit sold. Beyond cost savings, direct sourcing ensures superior product quality. Manufacturers control every step of production. They use high-grade raw materials and advanced technology. This results in durable, reliable PPR pipes. High-quality products reduce warranty claims and enhance customer satisfaction. This builds brand reputation and fosters repeat business. Furthermore, direct communication with manufacturers allows for precise customization. Businesses receive products tailored to their exact specifications. This reduces waste and optimizes project efficiency. All these factors contribute to a significantly higher ROI.

Avoiding Common Sourcing Pitfalls

Navigating the PPR pipe market requires vigilance. Several common pitfalls can undermine profitability and project success. Businesses must recognize and avoid these traps.

- Prioritizing Price Over Quality: Many businesses make the mistake of choosing the cheapest PPR pipes. This decision often leads to severe consequences. Cheap pipes can burst, contaminate water, and require constant repairs. The initial savings quickly disappear with costly re-plumbing. A quality PPR system, though more expensive upfront, lasts over 50 years. A cheaper alternative might fail in 5-7 years, leading to re-plumbing costs that far exceed any initial savings. Businesses should invest in certified brands. They must prioritize long-term quality and reliability.

- Mixing Incompatible Materials: Using different materials together can cause serious problems. For example, connecting copper to galvanized steel leads to corrosion. Using PVC cement on PPR pipes results in improper bonding. Mixing PPR brands can also cause issues due to different expansion rates. Businesses should use dielectric unions for dissimilar metals. They must match materials to proper joining methods. Sticking to one PPR brand per project ensures compatibility and system integrity.

- Under-Sizing Pipes: Incorrectly sized pipes lead to poor performance. This results in low water pressure and the inability to run multiple fixtures simultaneously. It also increases the workload on pumps and necessitates expensive re-piping. Professional pipe sizing calculations are essential. These calculations consider the number of fixtures, simultaneous use patterns, pipe length, elevation changes, and available pressure. For instance, a single bathroom typically needs 20mm pipes. A whole house with 2-3 bathrooms requires 25mm pipes. Large houses often need 32mm pipes.

- Inconsistency in Unbranded Batches: Buyers sometimes receive unbranded fittings that vary in quality. These might include off-white fittings that crack during fusion or adapters with stripped threads. Some fittings may even lack size markings. Businesses must inspect every shipment thoroughly. They should test samples before full-scale installation. Requesting batch-specific certification documents and pre-shipment samples for bulk orders helps verify color, weight, and markings.

- Lack of Traceability and Quality Assurance: Fittings sold without pressure ratings, material specifications, or manufacturer contact information pose a significant risk. Unusually low prices often indicate recycled content. Businesses should source from reputable suppliers and authorized distributors. They must verify certification marks like ISO and DIN. Inspecting the surface finish for defects is crucial. Buyers should avoid off-color or cloudy fittings. When using online marketplaces, filter for suppliers with verified credentials and third-party inspection records.

Future-Proofing Your Supply Chain

A direct partnership with a PPR pipe supplier Ningbo builds a resilient supply chain. This strategy prepares businesses for future market fluctuations and disruptions. Direct relationships foster trust and collaboration. Manufacturers can adapt more quickly to changing demands or new product specifications. This agility is crucial in a dynamic global market. Businesses gain direct access to innovation and product development. They can influence future product designs and integrate new technologies. This ensures their offerings remain competitive and relevant. A future-proof supply chain minimizes risks, maximizes efficiency, and secures long-term growth. It transforms a simple transaction into a strategic asset.

Direct sourcing PPR pipes maximizes profits. Businesses achieve significant cost savings and ensure superior quality. This strategic approach builds a resilient supply chain for 2026 and beyond. It secures a competitive edge. Your next step involves partnering with a leading PPR pipe supplier Ningbo. They offer advanced technology and competitive pricing. This decision drives long-term success. rocket emoji

FAQ

Why should businesses choose Ningbo for PPR pipe sourcing?

Ningbo offers a robust manufacturing ecosystem and access to advanced production technologies. Its strategic port location provides competitive pricing and efficient logistics. This combination ensures high-quality products and cost savings for businesses.