The Definitive 2026 Guide to PPR PVC and CPVC Pipe Fittings

Selecting the optimal pipe fitting is crucial for any water supply or irrigation project. The global pipe fittings market demonstrates significant scale, reaching an estimated USD 16.39 billion in 2024. This market continues its expansion, with projections indicating a robust 6.7% compound annual growth rate for pipes and pipe/hose fittings between 2024 and 2025. Professionals frequently evaluate options like PPR Pipe Fittings, PVC Pipe Fittings, and CPVC Pipe Fittings for diverse applications. Choosing the correct material ensures system integrity and longevity.

Key Takeaways

- PPR pipes are best for hot water and heating systems. They are also good for the environment.

- PVC pipes work well for cold water and drainage. They are also a low-cost choice.

- CPVC pipes can handle very hot water and strong chemicals. They are good for tough jobs.

- Choose the right pipe based on water temperature and what chemicals are in the water. This helps your system last longer.

- All three pipe types are easy to install. They are also lighter than metal pipes.

Understanding PPR Pipe Fittings for Water Systems

What are PPR Pipe Fittings Made Of?

PPR pipe fittings are a popular choice for modern plumbing systems. PPR stands for Random Copolymer Polypropylene, a type of plastic widely utilized in plumbing. The core material of PPR pipe fittings is polypropylene (PP-R), a random copolymer polypropylene produced via the gas phase method. Its structure features ethylene (PE) molecules randomly integrated within the polypropylene (PP) molecules. PPR pipe fittings derive their corrosion resistance from this specific chemical makeup, which includes a blend of propylene and ethylene.

Key Advantages of PPR Pipe Fittings

PPR pipe fittings offer several significant benefits, particularly in water systems. They possess low thermal conductivity, which translates into excellent thermal insulation properties. This characteristic helps maintain water temperature effectively.

| Property | PPR Pipe Fittings |

|---|---|

| Thermal Insulation | Low thermal conductivity |

This low thermal conductivity reduces energy loss in hot water systems, making them more energy-efficient. Less energy is needed to maintain the desired temperature. PPR fittings also prevent condensation in cold water systems, reducing the risk of mold and water damage. They perform well in demanding heating applications due to their ability to handle high temperatures.

Disadvantages of Using PPR Pipe Fittings

Despite their many advantages, PPR pipe fittings have certain limitations. One significant concern involves their sensitivity to UV radiation. Prolonged exposure to sunlight’s UV radiation can degrade PPR pipe material, impacting its durability and performance. This necessitates using pipes with UV stabilizers, protective coatings, or installation in shaded areas. Extended exposure to direct sunlight and UV radiation weakens the plastic, making it prone to cracking or discoloration over time.

Another disadvantage relates to extreme temperatures. While PPR pipes have a wide temperature range, extreme cold can lead to water freezing inside, potentially causing pipe damage. In hot climates, direct sunlight can cause overheating and deformation. Although PPR fittings are designed for a wide temperature range, extreme heat (exceeding 95°C) can cause deformation or weakening. Proper insulation is recommended to manage temperature stability in such environments.

Where are PPR Pipe Fittings Best Used?

PPR pipe fittings are an optimal choice for high-pressure and demanding applications. Their collective characteristics ensure both efficiency and durability across various systems. PPR pipes are highly valued for their ability to withstand high temperatures and pressures. This makes them ideal for residential, commercial, and industrial uses.

PPR pipe fittings find extensive use in several critical areas:

- Potable Water Supply Systems:

- Residential Buildings: PPR fittings provide efficient water distribution. They create seamless, leak-free joints. This ensures long-lasting plumbing.

- Commercial Establishments: PPR offers sustainable, eco-friendly plumbing solutions. These systems comply with water quality regulations for safe drinking water.

- HVAC Systems:

- Underfloor Heating Systems: PPR ensures even heat distribution. Seamless joints maintain system integrity. They also resist temperature fluctuations effectively.

- Radiator Installations: PPR offers corrosion resistance for longevity. It also contributes to energy efficiency in these systems.

- Sanitary Plumbing Systems:

- Wastewater Conveyance: PPR features corrosion resistance. It provides leak-free connections for reliable wastewater transport.

- Laboratories and Healthcare Facilities: PPR demonstrates chemical stability. It helps maintain high hygiene standards in sensitive environments.

PPR pipes offer excellent chemical resistance against water contaminants. They provide superior thermal insulation, which reduces heat loss and condensation. This makes them environmentally sustainable. The fusion welding technique creates reliable, leak-proof joints. This reduces maintenance needs. PPR is a preferred choice in modern plumbing due to these combined benefits.

Exploring PVC Pipe Fittings for Diverse Applications

What are PVC Pipe Fittings Made Of?

PVC pipe fittings are a common choice for many plumbing and irrigation needs. Polyvinyl chloride (PVC) forms the basis of these fittings. Manufacturers create PVC from vinyl chloride monomer. This process forms a polymer backbone similar to polyethylene. However, a chlorine atom replaces a hydrogen atom in PVC. This results in a material that is approximately 55% chlorine by mass. Raw PVC is difficult to process and lacks heat stability. Therefore, PVC pipe fittings include a complex mix of additives that enhance performance. These additives include fillers, stabilizers, lubricants, and processing aids. Plasticizers, UV stabilizers, impact modifiers (like ABS, CPE, EVA, MBS), reinforcing agents, and flame retardants are also part of the composition. CPVC is a variation of PVC. It has an increased chlorine content. This creates a distinct polymer with different properties.

Key Advantages of PVC Pipe Fittings

PVC pipe fittings offer numerous benefits. They are ideal for demanding uses like drainage systems, electrical conduits, and fencing due to their robustness and longevity. Municipal water systems and public buildings benefit from their cost-effectiveness and durability. PVC is significantly more affordable per foot than alternatives. These alternatives include ductile iron, steel, or concrete. Its inherent resistance to corrosion and chemical degradation eliminates the need for expensive coatings often required for metal pipes, further reducing costs. PVC pipes are also lightweight. This simplifies transport, handling, and installation. This results in faster installation times, lower labor costs, and reduced reliance on heavy machinery. Basic tools are sufficient for cutting and connecting PVC. This enhances efficiency and lowers overall project expenses. PVC pipes offer exceptional durability. They have a lifespan of 50 to 100 years. They resist corrosion and chemicals, unlike metal pipes. Their strong joints minimize leaks, reducing costly repairs and water loss. This translates to significant long-term maintenance savings. The smooth interior surface of PVC pipes reduces friction. This allows for more efficient water flow. This results in lower energy consumption for pumping systems and reduced operational costs for water distribution, improving efficiency in irrigation and drainage projects.

Disadvantages of Using PVC Pipe Fittings

Despite their many advantages, PVC pipe fittings have some limitations. They are not suitable for hot water applications. High temperatures can cause PVC to soften and deform, limiting their use to cold water systems. PVC can also become brittle in very cold temperatures. This makes them susceptible to cracking if subjected to impact or stress. While generally resistant to many chemicals, certain strong solvents and acids can degrade PVC. Users must check chemical compatibility for specific industrial applications. Prolonged exposure to direct sunlight and UV radiation can also degrade standard PVC. This leads to discoloration and reduced strength. Proper UV stabilization or protection is necessary for outdoor installations.

Where are PVC Pipe Fittings Best Used?

PVC pipe fittings demonstrate exceptional versatility across numerous applications. Their robust nature and chemical resistance make them ideal for a wide range of projects. These fittings are a staple in commercial and industrial plumbing systems. They efficiently join pipes, ensuring secure and leak-free connections. Installers use them to alter the flow path or change the size of pipes, providing flexibility in system design. PVC pipe fittings are also essential for maintaining sealed systems, securing liquids or gases under pressure.

Their utility extends significantly into residential plumbing. Homeowners often use them for redirecting plumbing around corners or connecting fixtures. In irrigation systems, PVC pipe fittings are indispensable. They help reduce water lines for specific irrigation needs, ensuring efficient water distribution. Utility applications also widely employ these fittings for various purposes, including water supply lines.

Here are some common applications where PVC pipe fittings excel:

- Commercial and Industrial Plumbing: They form the backbone of large-scale water and waste management systems.

- Pipe Connections: They provide reliable joints for diverse piping networks.

- Flow Path Modification: They allow for changes in direction or diameter within a pipeline.

- Pressure Systems: They secure liquids or gases under pressure effectively.

- Residential Plumbing: They facilitate household water supply and drainage.

- Irrigation Systems: They manage water flow for agricultural and landscaping needs.

- General Utility: They serve various other infrastructure requirements.

The adaptability and cost-effectiveness of PVC pipe fittings make them a preferred choice for many engineers and contractors. They offer a dependable solution for both simple and complex piping demands.

Delving into CPVC Pipe Fittings for High-Temperature Needs

What are CPVC Pipe Fittings Made Of?

CPVC pipe fittings originate from chlorinated polyvinyl chloride. This material differentiates itself from standard PVC through a specific manufacturing process. During production, a process called “free radical halogenation” introduces additional chlorine atoms into the molecular structure. This increases the chlorine content and alters the arrangement of atoms on the carbon backbone. CPVC is produced by chlorinating PVC resin. This chlorination process specifically alters the molecular structure of the material. This leads to its distinct properties compared to standard PVC.

| Feature | PVC | CPVC |

|---|---|---|

| Chlorine Atom Occupancy | 25% of carbon backbone bonding sites | Approximately 40% of carbon backbone bonding sites |

| Chlorine Content | 56.7 mass percent | Typically 63 to 69 mass percent (can be as high as 74 mass percent) |

| Molecular Structure | Carbon backbone with hydrogen and chlorine | Carbon backbone with a higher proportion of chlorine atoms, providing protection to the carbon chain |

Key Advantages of CPVC Pipe Fittings

CPVC pipe fittings offer significant advantages, especially in high-temperature industrial environments. They maintain exceptional mechanical strength even at elevated operating temperatures. For instance, Corzan CPVC’s pressure rating is 25% higher than other CPVC materials at 180°F (82°C). It can sustain pressure-bearing capabilities for 50 years or more.

- High-Temperature Tolerance: CPVC pipes can endure temperatures up to 200°F (93°C). This makes them suitable for transporting hot industrial fluids and steam. This prevents warping, cracking, or degradation in demanding industrial processes. These processes include chemical processing, food production, and power generation.

- Superior Chemical Resistance: CPVC pipes resist a wide array of acids, alkalis, and other chemicals. These chemicals are frequently encountered in industrial processes. This prevents corrosion, leaks, and system failures often seen with metal pipes. It ensures integrity in industries like pharmaceuticals, chemical processing, and manufacturing.

- Additional Safety: CPVC has lower thermal conductivity. This reduces heat loss and keeps the pipe surface temperature lower. It minimizes the risk of burns to personnel.

- Low Flame and Smoke Characteristics: CPVC has a high flash ignition temperature of 900°F (482°C). It also has an exceptionally high limiting oxygen index (LOI) of 60. This means it does not easily sustain combustion, enhancing safety in industrial plants.

Disadvantages of Using CPVC Pipe Fittings

Despite its benefits, CPVC pipe fittings have certain limitations. CPVC pipes are known to become brittle over time. This is particularly true in cold environments. This increased brittleness makes them more vulnerable to cracking when subjected to physical stress or impact. This characteristic is a significant concern in regions with low temperatures. It also applies where pipes might experience mechanical stress. ASTM F441 CPVC pipes can become brittle over time, especially under stress or extreme temperatures. This increases their susceptibility to cracking and failure. This issue is particularly exacerbated in colder climates. Pipes can freeze and break easily in these conditions. For instance, a CPVC pipe exposed to freezing temperatures may shatter if water expands inside. This leads to costly repairs and water damage.

Where are CPVC Pipe Fittings Best Used?

CPVC pipe fittings are a preferred choice for applications demanding high-temperature resistance and chemical stability. Their unique properties make them suitable for diverse environments, from residential plumbing to complex industrial systems.

CPVC excels in hot and cold water plumbing distribution. Installers use CPVC for internal plumbing and terrace pipelines in homes, specifically for bathrooms, kitchens, and utility areas. This includes residential hot and cold water plumbing, encompassing kitchens, bathrooms, water heaters, and service lines. CPVC also handles hot water supply in larger facilities like hotels, hospitals, and commercial complexes.

Beyond residential and commercial buildings, CPVC pipe fittings find extensive use in specialized systems. They are crucial for fire protection systems in various dwelling types and occupancies, adhering to standards like NFPA 13D, 13R, and 13. Engineers also specify CPVC for reclaimed water piping, often identified by its purple color. Chilled water piping and hydronic piping and distribution systems, such as those for radiators and fan coils, also benefit from CPVC’s capabilities.

Industrial applications frequently rely on CPVC due to its robust nature. It offers resistance to chemical exposure and extreme conditions. This includes process lines, water treatment systems, and solar heating networks. Chemical processing plants, laboratories, and manufacturing facilities utilize CPVC, especially when handling corrosive substances and high-temperature liquids. CPVC’s ability to withstand harsh industrial environments makes it a reliable solution for critical infrastructure.

CPVC pipe fittings provide a dependable solution for systems requiring durability under thermal and chemical stress. Their versatility ensures efficient and safe fluid conveyance across many sectors.

Direct Comparison: PPR vs. PVC vs. CPVC Pipe Fittings

Professionals often compare PPR, PVC, and CPVC pipe fittings when selecting materials for plumbing and fluid conveyance systems. Each material offers distinct advantages and limitations. Understanding these differences helps engineers and project managers make informed decisions. This section provides a direct comparison of their performance across critical parameters.

Which Pipe Fitting Handles Temperature Best?

Temperature tolerance represents a crucial factor in pipe fitting selection. Each material performs differently under varying thermal conditions.

PPR pipe has a maximum allowable operating temperature of 70°C. PPR fittings can withstand continuous temperatures up to 95°C. This makes them suitable for many hot water applications.

PVC pipe is suitable for temperatures under 140° Fahrenheit (60°C). This limits its use primarily to cold water systems. High temperatures cause PVC to soften and deform.

CPVC pipe demonstrates superior high-temperature performance. It can handle temperatures under 200° Fahrenheit (93°C). CPVC has a maximum service temperature of approximately 93°C. This enhanced thermal resistance makes CPVC ideal for hot water distribution and industrial processes.

| Pipe Material | Maximum Operating Temperature |

|---|---|

| PPR | 70°C (158°F) |

| PVC | 60°C (140°F) |

| CPVC | 93°C (200°F) |

CPVC clearly offers the best performance in high-temperature environments. PPR provides a strong alternative for many hot water needs, while PVC remains restricted to cold water applications.

How Do Pressure Ratings Compare?

Pressure ratings are vital for ensuring system integrity and preventing failures. Each pipe material exhibits different pressure-bearing capabilities, often influenced by temperature.

For PPR pipe fittings, pressure ratings use the PN (Nominal Pressure) rating system. Manufacturers express this in bars (e.g., PN 10, PN 16, PN 20, PN 25). This rating signifies the maximum allowable continuous operating pressure at a reference temperature of 20°C (68°F). For example, a PN 20 fitting can withstand 20 bar at 20°C. However, the pressure-bearing capacity of PPR significantly decreases as the fluid temperature increases. PPR’s mechanical strength diminishes with higher temperatures. Manufacturers provide derating tables to specify reduced maximum working pressures at elevated temperatures. Considering this temperature-pressure relationship in system design is crucial to prevent failure, especially in hot water applications. When selecting a PN rating, factors such as maximum operating pressure, peak fluid temperature, pressure surges, and desired service life must be considered. Engineers often apply a safety factor.

PVC pipe fittings generally offer good pressure resistance for cold water applications. Their pressure rating decreases significantly with increasing temperature, similar to PPR but with a lower overall temperature threshold. CPVC pipe fittings maintain higher pressure ratings at elevated temperatures compared to both PVC and PPR. This makes CPVC a robust choice for pressurized hot fluid systems.

Which Pipe Fitting Offers Superior Chemical Resistance?

Chemical resistance determines a pipe material’s suitability for transporting various fluids without degradation. Each material has specific strengths and weaknesses against different chemicals.

PPR pipe fittings demonstrate excellent resistance to a wide array of acids and bases. They can withstand dilute and moderately concentrated acids such as hydrochloric acid, sulfuric acid, and acetic acid. In laboratory settings, PPR pipes transporting acidic solutions remain unaffected over extended periods. PPR exhibits high resistance to common bases like sodium hydroxide and potassium hydroxide. In wastewater treatment plants, PPR pipes exposed to alkaline effluents maintain their integrity without significant degradation. PPR fittings are particularly resistant to both acidic and alkaline solutions. This makes them suitable for systems transporting fluids outside the neutral pH range. They show long-term resistance to low and medium concentrations of many common acids and bases, including hydrochloric acid and sodium hydroxide. These chemicals are critical in industrial and chemical processes. PPR pipe fittings can be safely used in pharmaceutical facilities to transport hydrochloric acid or sodium hydroxide solutions. Their resistance to these strong acids and bases ensures the integrity of the piping system, preventing leaks and potential hazards in such critical environments. It is important to note that resistance can vary based on concentration, temperature, and exposure duration. Manufacturers typically provide chemical resistance charts to assist engineers in selecting appropriate materials for specific chemical combinations.

PVC pipe fittings offer good resistance to many acids, alkalis, and salts. However, certain organic solvents and strong oxidizing agents can degrade PVC. CPVC generally provides broader chemical resistance than standard PVC, especially at higher temperatures. Its increased chlorine content enhances its ability to resist a wider range of corrosive chemicals.

What is the Lifespan and Durability of Each?

The lifespan and durability of pipe fittings are critical considerations for any plumbing project. Each material offers different long-term performance characteristics. PPR (Polypropylene Random Copolymer) pipe fittings are designed for long-term durability. They last for decades under normal conditions. Their resistance to corrosion, scaling, and chemical reactions makes them suitable for water supply and heating systems. In residential plumbing, PPR fittings can outperform traditional metal fittings. Under normal conditions, PPR pipes are designed to last for 50 to 100 years. This makes them a preferred choice for long-term plumbing. When installed correctly and used within recommended pressure and temperature limits, they can remain functional for several decades without major repairs. For instance, in domestic hot and cold water systems, PPR pipes typically have a lifespan of around 50 to 70 years. In industrial applications, while conditions are more demanding, their lifespan can still be long with proper care.

CPVC pipe fittings typically have a lifespan of 50 to 75 years under ideal conditions. In residential plumbing, where temperatures and pressures are moderate, they tend to achieve their longest lifespans. Industrial settings might see slightly shorter service times due to specific chemicals and mechanical stresses. However, CPVC remains a high-performing non-metallic piping material. CPVC pipes generally last for a minimum of 50 years under normal operating conditions. Proper installation and adherence to recommended operating temperatures and pressures contribute significantly to their longevity. CPVC’s resistance to corrosion and scaling helps maintain the integrity of the pipes over time. PVC pipe fittings also offer excellent durability, often lasting 50 years or more in appropriate applications, particularly for cold water and drainage systems. Their resistance to corrosion is a key factor in their long service life.

Which Pipe Fitting is Most Cost-Effective?

Cost-effectiveness involves more than just the initial purchase price of the pipe fittings. It includes installation costs, maintenance, and potential replacement expenses over the system’s lifespan. PVC pipe fittings generally have the lowest upfront material cost. This makes them an attractive option for budget-conscious projects, especially for cold water supply and drainage. However, their limitations in high-temperature applications mean they are not suitable for all uses.

PPR pipe fittings often have a higher initial material cost compared to PVC. However, their long lifespan and minimal maintenance requirements can lead to lower overall lifecycle costs. PPR’s excellent thermal insulation properties also contribute to energy savings in hot water systems. CPVC pipe fittings typically fall in the middle to higher range for material costs. Their superior temperature and chemical resistance justify this price point for specific applications. While more expensive than PVC, CPVC offers a cost-effective solution for systems requiring robust performance in demanding environments. The long-term durability of both PPR and CPVC often outweighs the initial material cost difference when considering total cost of ownership.

How Easy is Each Pipe Fitting to Install?

Installation ease significantly impacts project timelines and labor costs. Each pipe fitting material has distinct installation methods. PPR fittings offer significant advantages in installation ease. They utilize heat fusion welding for leak-proof joints. This method is faster and safer than traditional methods like soldering or threading. This process, along with the lightweight nature of PPR, simplifies transportation and handling. The reduced installation time directly translates to lower labor costs compared to labor-intensive traditional fittings that often require skilled technicians. PPR pipe installation labor costs are often 15-25% lower than CPVC due to faster jointing and prefabrication capabilities. While PPR components may cost 20-30% more than CPVC, the reduced labor expenses can offset this, especially on larger projects where specialized welding equipment investment quickly pays off.

PVC and CPVC pipe fittings typically use solvent cement for joining. This method is relatively straightforward and does not require specialized heating equipment like PPR. Installers apply a primer and then solvent cement to the pipe and fitting, creating a strong chemical bond. This process is quick and efficient for many applications. CPVC’s simplicity and lower upfront material cost make it practical for small repairs. However, its initial savings can be negated if early replacement or significant repairs are needed. While solvent welding is generally easy, proper technique is crucial to ensure leak-free connections. The lightweight nature of all three materials simplifies handling and reduces the need for heavy machinery during installation.

What is the Environmental Impact of Each Pipe Fitting?

The environmental impact of pipe fittings extends beyond their initial production. It encompasses raw material extraction, manufacturing processes, energy consumption during use, and end-of-life disposal or recycling. Understanding these factors helps in making environmentally conscious choices for plumbing and fluid conveyance systems.

CPVC pipe fittings raise environmental concerns due to the chlorine used in their manufacturing process. The production of CPVC involves extracting raw materials. This includes chlorine from salt through energy-intensive electrolysis and ethylene from fossil fuels. These processes contribute to greenhouse gas emissions. The chlorination process converts PVC to CPVC. This requires careful handling of chlorine gas to prevent leakage. Such leakage can harm the environment and human health. During use, CPVC offers environmental benefits. Its insulation properties contribute to energy efficiency in heating and cooling systems. This reduces heat loss or gain and lowers the carbon footprint. CPVC’s chemical resistance also prevents leaks of hazardous substances. This safeguards against environmental contamination. At the end of its life, CPVC can be recycled, though the process is complex. Disposal options include landfilling, where it remains stable but consumes space. Incineration is another option, but it necessitates careful control to manage emissions of chlorine-containing compounds.

PVC pipe fittings also present environmental concerns due to chlorine use in their production. However, PVC is recyclable in some regions. This offers a potential pathway for reducing its environmental footprint.

PPR pipe fittings are generally considered more eco-friendly. They are 100% recyclable. Their production and disposal have a lower environmental impact.

| Pipe Type | Environmental Concerns (Manufacturing & Disposal) |

|---|---|

| CPVC | Concerns due to chlorine use in manufacturing process. |

| PVC | Concerns due to chlorine use in production; recyclable in some regions. |

| PPR | Considered more eco-friendly; 100% recyclable with lower environmental impact during production and disposal. |

PPR pipes are made from recyclable thermoplastic material. This minimizes their environmental impact compared to non-recyclable alternatives. Their production involves processes with lower greenhouse gas emissions. Manufacturing PPR pipes requires fewer natural resources compared to traditional materials like metal or PVC. This contributes to resource conservation. PPR pipes offer an extended service life. They are corrosion-resistant. This reduces the need for frequent replacements. It also lessens the environmental impact of disposing of worn-out pipes. Low maintenance also means fewer materials are used over time.

- Eco-Friendly Composition: PPR pipes are made from recyclable thermoplastic material. This minimizes environmental impact compared to non-recyclable alternatives. Their production involves processes with lower greenhouse gas emissions.

- Reduced Resource Consumption: Manufacturing PPR pipes requires fewer natural resources compared to traditional materials like metal or PVC. This contributes to resource conservation.

- Longevity and Low Maintenance: PPR pipes offer an extended service life. They are corrosion-resistant. This reduces the need for frequent replacements. It also lessens the environmental impact of disposing of worn-out pipes. Low maintenance also means fewer materials are used over time.

Choosing the Right Pipe Fitting for Your Project

Selecting the appropriate pipe fitting material is a critical decision for any plumbing or fluid conveyance project. This choice directly impacts system performance, longevity, and overall cost-effectiveness. Project managers and engineers must carefully evaluate the specific requirements of each application to ensure optimal material selection.

Best for Potable Water Systems?

For potable water systems, material safety and compliance with health standards are paramount. The chosen pipe fittings must not leach harmful substances into the drinking water. CPVC (Chlorinated Polyvinyl Chloride) is an advanced form of PVC, enhanced with chlorine for improved temperature resistance and chemical durability. It is widely used in residential and industrial plumbing for safely handling both hot and cold potable water. Manufacturers design CPVC formulations specifically to withstand water temperatures up to 200ºF.

NSF-certified CPVC fittings are particularly suitable for potable water systems, including residential hot and cold water distribution. NSF certification involves rigorous testing for material safety, structural integrity, and performance, especially concerning contact with drinking water. Relevant standards include NSF/ANSI 14 for plastic piping components, NSF/ANSI/CAN 61 to prevent contaminant contribution to drinking water, and NSF/ANSI 372 for lead content compliance. CPVC compounds certified by NSF/ANSI comply with regulations for potable water materials, covering chemical contaminant health requirements, long-term physical strength, and performance. These products are also subject to unannounced inspections and annual testing, ensuring consistent quality and safety. PPR also serves as an excellent choice for potable water systems due to its inert nature and resistance to scaling, which maintains water quality.

Best for Hot Water Applications?

Hot water applications demand pipe fittings capable of withstanding continuous elevated temperatures without degradation or loss of structural integrity. PEX (cross-linked polyethylene) systems are designed to work effectively with hot water recirculation. This ensures immediate hot water availability and reduces water waste. PEX offers significant flexibility, allowing routing in continuous loops. This minimizes the need for numerous fittings and simplifies installation. Unlike metal pipes, PEX does not corrode or build up scale, leading to cleaner water flow and reduced maintenance.

PEX also demonstrates excellent thermal efficiency. It has lower thermal conductivity than metal pipes, which helps maintain consistent water temperature from the heater to fixtures, reducing energy waste. PEX pipes can last up to 50 years under normal operating conditions, offering long-term durability. PEX is rated for use at temperatures up to 180°F (82°C), making it highly suitable for home hot water distribution. CPVC also excels in hot water applications, handling temperatures up to 200°F (93°C), making it a robust option for both residential and industrial hot water distribution. PPR fittings can withstand continuous temperatures up to 95°C, making them suitable for many hot water applications as well.

Best for Cold Water Supply?

Cold water supply lines, especially those installed underground, require materials that offer durability, resistance to corrosion, and cost-effectiveness. Several materials prove suitable for these demanding conditions. Polyvinyl chloride (PVC) is an inexpensive, reliable, and durable option. It is rigid, resists corrosion, and can last over 100 years. High-density polyethylene (HDPE) pipe is another good choice due to seamless plastic fusion connections, which prevent leaks from joints or degrading glues. HDPE is extremely durable, with a lifespan upwards of 100 years, resistant to corrosion, and flexible. Its flexibility increases resistance to shifting soils and allows for trenchless installation.

Traditional materials also remain viable options. Brass and Type “L” copper or heavier are commonly used for underground cold water lines. Cast iron also serves this purpose effectively. For copper, Type K (thickest-walled) is generally used for underground lines and between water mains and meters. Type L (thicker-walled) is considered standard for water services both inside and outside structures. CPVC (Chlorinated polyvinyl chloride) is popular due to cost savings over metal piping and is lighter than copper, leading to faster installations. However, it requires care during installation to prevent sagging. PEX tube is less costly and easier to install than copper. Installers can bend it around corners, reducing the need for elbows. PEX is forgiving, as kinks can be repaired with heat, and it offers resistance to scaling, chlorine, and corrosion, with no need for fastening. Temp-tite pressure pipe (epoxy-lined transites core pipe) may also be used underground.

Best for Irrigation Systems?

Choosing the right pipe fitting material for irrigation systems ensures efficient water delivery and long-term system integrity. Agricultural projects often require materials that balance affordability, durability, and high-pressure tolerance. PVC (Polyvinyl Chloride) and HDPE (High-Density Polyethylene) are prominent choices, each offering distinct advantages.

| Feature / Material | PVC (Polyvinyl Chloride) | HDPE (High-Density Polyethylene) |

|---|---|---|

| Strength & Durability | High strength, withstands high water pressure, resistant to cracking/breaking | Highly flexible, impact-resistant, adapts to uneven terrain/soil movement |

| Water Flow | Smooth interior for efficient water flow (minimizes friction) | N/A |

| Corrosion/Chemical Resistance | Resistant to corrosion & chemicals (ideal for mineral-rich/chemically treated water) | N/A |

| Installation & Maintenance | Easy to install, lightweight, simple joint fittings, reduces labor costs | Requires specialized welding techniques for joining (higher installation costs) |

| Flexibility | Less flexible (slightly rigid) | Highly flexible |

| UV Resistance | Requires UV-resistant shielding if above ground | Resistant to UV damage (withstands prolonged sun exposure) |

| Pressure Tolerance | High water pressure tolerance | Lower pressure tolerance compared to PVC |

| Joints | Simple joint fittings | Fused together, creating seamless, leak-free system |

| Common Use Case | Most agricultural projects (balance of affordability, durability, high pressure tolerance) | Areas with shifting soil or extreme temperatures, where flexibility is key |

PVC pipes are a common choice for most agricultural projects. They offer a good balance of affordability, durability, and high-pressure tolerance. Their smooth interior minimizes friction, ensuring efficient water flow. PVC also resists corrosion and chemicals, making it ideal for mineral-rich or chemically treated irrigation water. Installation is straightforward due to its lightweight nature and simple joint fittings, which reduces labor costs.

HDPE pipes excel in areas with shifting soil or extreme temperatures. Their high flexibility and impact resistance allow them to adapt to uneven terrain and soil movement. HDPE is also resistant to UV damage, withstanding prolonged sun exposure without degradation. While HDPE requires specialized welding techniques for joining, creating seamless, leak-free systems, its flexibility and durability make it invaluable in challenging environments.

CPVC pipes also offer significant benefits in agricultural settings, particularly for specialized applications:

- CPVC pipes provide enhanced temperature resistance compared to PVC. This makes them suitable for hot water distribution in greenhouses and controlled-environment agriculture.

- CPVC water plumbing systems are known for their long lifespan and high resistance to corrosion.

- CPVC pipes handle warm water distribution without warping or degrading. This ensures a consistent temperature for sensitive crops.

- CPVC pipes’ chemical resistance ensures the longevity of the system in agricultural settings. Fertilizers and pesticides are often mixed with irrigation water in these environments.

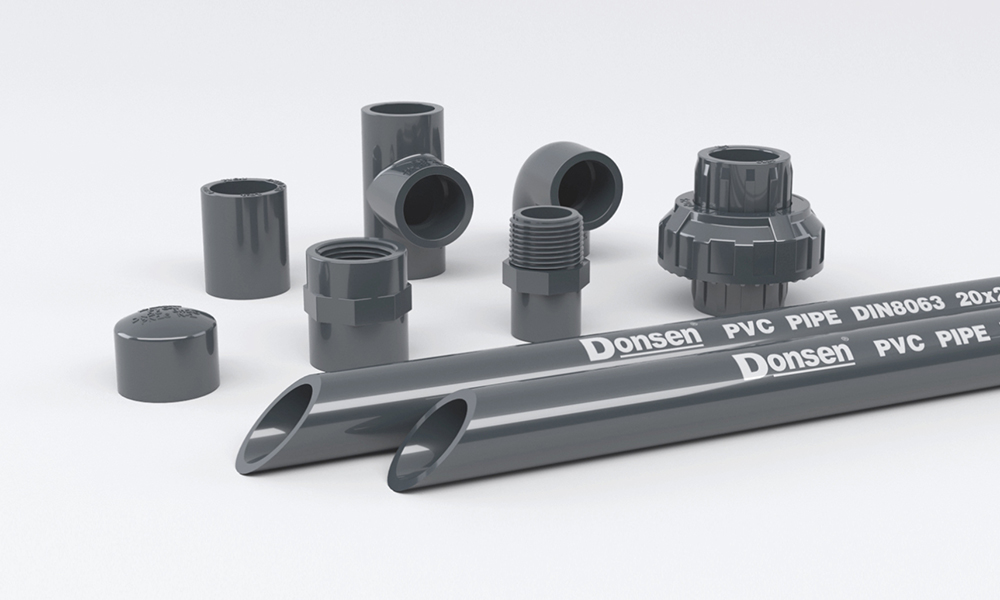

Donsen offers a comprehensive range of plastic pipelines for irrigation systems, including PVC, CPVC, and PE pipes and fittings. These products ensure efficient and reliable water distribution for agricultural needs.

Best for Industrial and Commercial Use?

Industrial and commercial environments demand pipe fittings that withstand extreme conditions. These conditions include caustic chemicals, volatile solvents, severe corrosion, and high temperatures. Material selection is critical for safety, operational efficiency, and system longevity.

Specialized materials are often necessary for these demanding applications:

- Exotic Alloys (Hastelloy, titanium, Inconel, Monel): Chemical processing plants prefer these alloys. They handle caustic acids, volatile solvents, severe corrosion environments, and high-temperature service. They are crucial where specific chemical compatibilities are required.

- Specialized Plastics (PTFE): Chemical processing plants use PTFE for compatibility with various process streams. It offers excellent corrosion resistance.

- Stainless Steel (Grades 304 and 316): Stainless steel is essential in chemical processing for its corrosion resistance and severe service applications.

- PVC and Plastic: These materials are increasingly popular in chemical handling. They offer corrosion resistance, light weight, and cost advantages. However, they have pressure and temperature limitations.

For less extreme industrial and commercial applications, such as general water supply, heating, and non-corrosive fluid transport, PPR and CPVC offer robust solutions. PPR pipes and fittings provide excellent thermal insulation and resistance to scaling, making them suitable for HVAC systems and hot water distribution in commercial buildings. CPVC, with its superior high-temperature and broad chemical resistance, is ideal for process lines, water treatment systems, and other applications where fluids are hot or corrosive. Donsen provides a wide array of plastic pipeline solutions, including PPR, PVC, and CPVC pipes and fittings, catering to the diverse and stringent requirements of industrial and commercial sectors.

Best for Residential Plumbing?

Residential plumbing systems require materials that ensure safe, reliable, and long-lasting water delivery for both hot and cold applications. Homeowners prioritize durability, ease of installation, and cost-effectiveness.

PPR (Polypropylene Random Copolymer) pipes and fittings are an excellent choice for residential plumbing. They offer a long lifespan, often exceeding 50 years, due to their resistance to corrosion, scaling, and chemical reactions. PPR’s low thermal conductivity also makes it energy-efficient for hot water systems, reducing heat loss. Its fusion welding method creates seamless, leak-proof joints, ensuring system integrity. Donsen’s PPR pipes and fittings are widely used for water supply and heating in home decoration.

CPVC (Chlorinated Polyvinyl Chloride) is another strong contender for residential plumbing, particularly for hot water distribution. CPVC handles temperatures up to 200°F (93°C) without degradation. This makes it a reliable option for kitchens, bathrooms, and water heater connections. CPVC also resists corrosion and maintains water quality, providing a safe and durable solution for potable water systems.

PEX (cross-linked polyethylene) offers significant flexibility, allowing installers to route it in continuous loops. This minimizes the need for numerous fittings and simplifies installation. PEX does not corrode or build up scale, leading to cleaner water flow. It also has lower thermal conductivity than metal pipes, helping maintain consistent water temperature. PEX is rated for use at temperatures up to 180°F (82°C), making it highly suitable for home hot water distribution.

PVC (Polyvinyl Chloride) pipes are primarily used for cold water supply and drainage systems in residential settings. They are cost-effective, durable, and resistant to corrosion. However, their temperature limitations restrict their use in hot water applications.

Donsen offers a comprehensive range of products, including PPR, PVC, and CPVC pipes and fittings, as well as various plastic valves. These products are widely used in civil water supply, building drainage, water supply and heating, and home decoration, providing reliable solutions for every residential plumbing need.

2026 Outlook: Future Trends in Pipe Fittings

What Emerging Technologies are Shaping Pipe Fittings?

Emerging technologies significantly influence the evolution of pipe fittings. Advanced composites and eco-friendly materials, including polyethylene and other composites, offer durability and corrosion resistance comparable to traditional steel and iron. These modern industrial plastics and composites are recyclable, which minimizes waste and reduces energy consumption during manufacturing. Bio-based plastics, made from renewable biomass, are also gaining traction. These biodegradable plastics will likely see increased use in residential pipe systems, decaying without leaving harmful residues. Furthermore, smart materials feature unique properties like self-healing capabilities, enhanced corrosion resistance, and improved strength. These innovations lead to reduced maintenance costs and longer pipeline lifespans. Nanotechnology also plays a role. Integrating nanoparticles into pipe materials creates pipes that are lighter, stronger, and more durable, suitable for demanding applications.

How is Sustainability Impacting Pipe Manufacturing?

Sustainability profoundly impacts pipe manufacturing. Manufacturers increasingly use recycled materials to reduce costs. Equipment and processes ensure quality when incorporating these materials. They improve recycled raw materials with additives like polymer stabilizers and compatibilizers to match virgin material properties. A key method involves reprocessing self-made scrap material generated during manufacturing. The 3-layer cross-head technology allows for the use of lower-cost recycled or off-spec materials in the main volume of the pipe. Virgin raw material is used for the inner or outer layers to maintain integrity and functionality. This technology integrates into existing extruder machines and uses gravimetric feeder systems to ensure precise layer thickness and consistent material quality. Manufacturers incorporate recycled polyethylene, including both post-consumer and post-industrial plastics, into HDPE pipe fitting production. This approach reduces the demand for new petroleum-based materials and diverts plastic waste from landfills. Companies like Advanced Drainage Systems (ADS) recycle over half a billion pounds of plastic annually, demonstrating substantial industry efforts.

What is the Future of Pipe Fittings?

The future of pipe fittings points towards significant shifts in material demand and technological adoption. Metallic fittings will likely lead the market, holding an estimated 72.1% share in 2025. Their high mechanical strength, temperature tolerance, and corrosion resistance drive this. However, the industry sees a rising adoption of advanced materials like stainless steel and plastic composites for enhanced durability and corrosion resistance. Volatility in raw material prices for traditional materials, such as steel, copper, and PVC resins, compels manufacturers to consider alternative materials like composite and plastic fittings. There is a growing focus on eco-friendly and recyclable materials due to green building initiatives and energy-efficient plumbing systems. This includes increased use of advanced materials such as stainless steel alloys, composite plastics (PVC, CPVC, PEX), and corrosion-resistant polymers. These materials offer enhanced chemical resistance, easier installation, longer service life, and reduced maintenance.

Making an informed decision requires careful evaluation of project specifics. Consider temperature, pressure, chemical exposure, and budget. Environmental impact also plays a role. Each pipe fitting material offers distinct advantages. PPR excels in hot water and eco-friendliness. PVC provides cost-effective solutions for cold water. CPVC handles high temperatures and harsh chemicals. Selecting the optimal fitting ensures system longevity and performance. Match material properties to application needs for the best results.

FAQ

What is the main difference between PVC and CPVC pipe fittings?

CPVC pipe fittings contain more chlorine than PVC. This additional chlorine allows CPVC to withstand higher temperatures. It also provides superior chemical resistance. PVC is primarily for cold water and drainage. CPVC handles both hot and cold water applications.

Are PPR pipe fittings safe for drinking water?

Yes, PPR pipe fittings are safe for drinking water systems. They are inert and do not leach harmful substances. PPR resists scaling and corrosion. This maintains water quality. Many certifications confirm their suitability for potable water.

Why is CPVC often preferred over PVC for residential plumbing?

CPVC is often preferred for residential plumbing because it handles hot water. PVC cannot withstand high temperatures. CPVC’s enhanced temperature resistance makes it suitable for both hot and cold water distribution throughout a home.

Can PVC pipe fittings be used for hot water applications?

No, PVC pipe fittings are not suitable for hot water applications. High temperatures cause PVC to soften and deform. This limits its use to cold water systems. Using PVC with hot water can lead to system failure.

What makes PPR pipe fittings a sustainable choice?

PPR pipe fittings are a sustainable choice because they are 100% recyclable. Their production involves lower greenhouse gas emissions. They also offer an extended service life. This reduces the need for frequent replacements and minimizes waste.