PVC Flanges and Male Threaded Tees The Ultimate Installation Guide for Industrial Piping

Proper installation of PVC flanges and PVC Male Threaded Tee is crucial for preventing costly leaks in industrial piping. Precise installation directly impacts operational safety and significantly extends system longevity. This comprehensive guide provides essential, step-by-step instructions. It ensures businesses achieve truly leak-free and reliable industrial PVC piping systems.

Key Takeaways

- Proper installation of PVC parts prevents leaks. It keeps the system safe and makes it last longer.

- PVC is good for industrial use. It resists chemicals, is light, and helps liquids flow well.

- Always prepare pipes and fittings well. Clean them, dry-fit them, and use the right sealants.

- Apply solvent cement carefully for flanges. Tighten bolts correctly. Use the right gasket.

- Prepare threads well for threaded tees. Tighten them enough but not too much. This avoids damage.

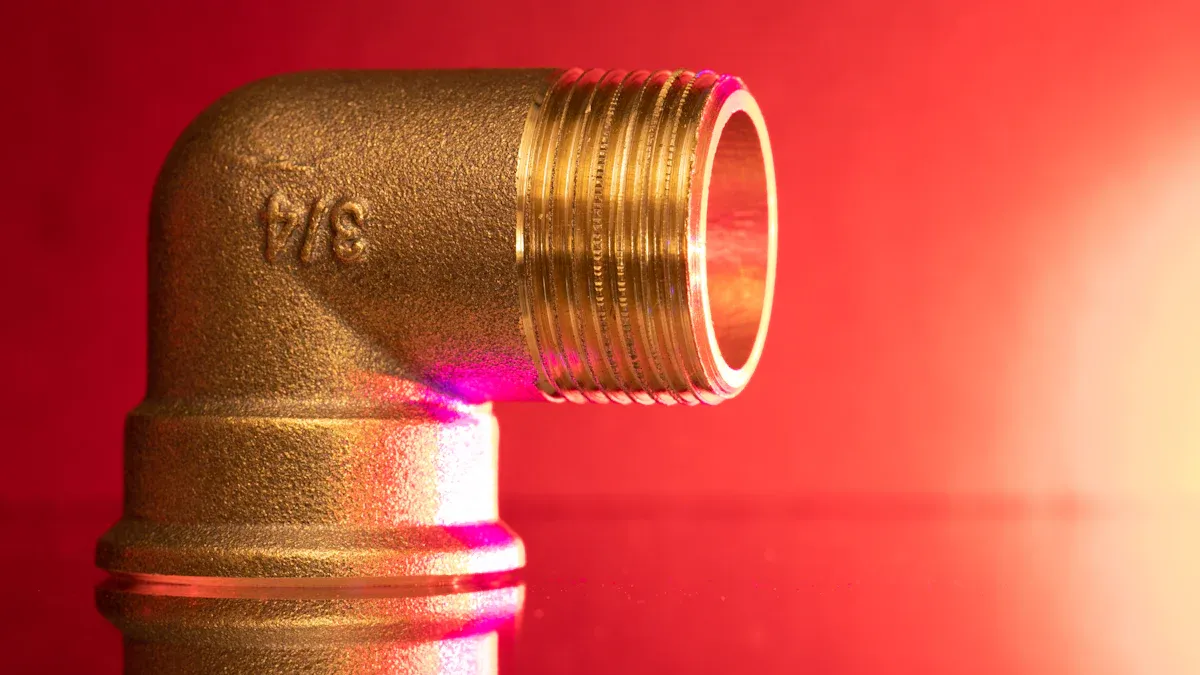

Understanding Industrial PVC Components

The Role of PVC Flanges in Industrial Systems

PVC flanges provide a critical connection point in industrial piping systems. They allow for easy assembly and disassembly of pipes, valves, and equipment. Workers can quickly connect or disconnect sections for maintenance, inspection, or system modifications. This modularity significantly reduces downtime and simplifies complex installations. Flanges ensure a secure, leak-proof seal when properly installed, which is essential for maintaining system integrity and operational safety in demanding industrial environments.

Benefits of PVC Male Threaded Tee for Branching

A PVC Male Threaded Tee offers exceptional versatility for creating branch lines in a piping system. This component allows for a secure, threaded connection, enabling easy integration of additional pipes or instruments. For robust industrial needs, 1-inch to 1 1/4-inch Schedule 80 PVC tees offer the durability and capacity to handle higher flow rates and pressure requirements, ensuring secure and efficient system operation. These are commonly used in light commercial plumbing or mechanical rooms. Schedule 80 PVC tees are also used in commercial plumbing systems to withstand high PSI loads and in water treatment plants to support fluctuating flows. The PVC Male Threaded Tee is particularly advantageous due to its superior resistance properties:

- High corrosion resistance.

- Commonly used in applications involving acids, salts, water, alkalis, oil, and many other chemicals.

- Maximum working temperature of 140ºF, depending on the chemical used.

- Ideal for applications involving strong cleaning agents, industrial chemicals, or saltwater.

- Does not rust or degrade like metal counterparts.

- Withstands aggressive fluids in water treatment plants.

- Resistant to acids, bases, and salts in chemical handling applications.

Advantages of PVC in Industrial Applications

PVC stands out as a preferred material for industrial piping due to its numerous benefits. It offers excellent chemical resistance, making it suitable for transporting a wide range of corrosive substances without degradation. PVC’s lightweight nature simplifies handling and installation, reducing labor costs and effort. Its smooth interior surface minimizes friction, promoting efficient fluid flow and reducing energy consumption. Furthermore, PVC provides a cost-effective solution compared to many metal alternatives, delivering long-term performance and reliability in diverse industrial settings. These advantages collectively contribute to the efficiency and longevity of industrial piping infrastructure.

Essential Tools and Materials for Installation

Successful PVC piping installation relies heavily on using the correct tools and high-quality materials. Proper preparation ensures a secure, leak-free system. Installers must gather all necessary items before beginning any work. This proactive approach saves time and prevents costly errors.

Required Hand Tools for PVC Work

Specific hand tools make PVC work efficient and precise. PVC pipe cutters are essential for clean, straight cuts. They feature ratcheting mechanisms for easy cutting without excessive force. Their blades minimize chipping and cracking of the PVC material, ensuring a smooth surface for connections. Deburring tools remove rough edges from cut pipes. This step prevents obstructions and ensures proper fit.

| Part # | Description | Application |

|---|---|---|

| RS1 | 1 1/2″ Ratchet shear | Professional Tools For Plastic |

| 3-6PVC | Cutter wheel for TC3Q, TC4Q, TC5Q, TC6Q | 3-6″ PVC, 4″ Heavy wall |

| DEB3 | Pocket Sized Deburring Tool | Aluminum, Copper & Steel |

Other vital tools include measuring tapes, markers, and clean rags. A torque wrench is also crucial for tightening flange bolts to exact specifications.

Selecting Sealants and Adhesives

Choosing the right sealants and adhesives is paramount for leak-proof connections. Solvent cement creates a strong, permanent bond for PVC pipe and fitting joints. Installers must select a cement specifically formulated for industrial PVC applications. For threaded connections, a high-quality thread sealant or PTFE tape prevents leaks. These materials fill microscopic gaps in the threads, ensuring a tight seal. Always verify the sealant’s compatibility with PVC and the specific chemicals the system will transport.

Personal Protective Equipment for Safety

Safety always comes first during any industrial installation. Personal Protective Equipment (PPE) protects workers from potential hazards. Safety glasses shield eyes from flying debris and chemical splashes. Chemical-resistant gloves protect hands from solvent cements and other chemicals. A respirator may be necessary when working in poorly ventilated areas to prevent inhalation of fumes. Wearing long sleeves and pants also offers additional skin protection. Prioritizing safety ensures a healthy work environment and prevents accidents.

Preparing for Flange and PVC Male Threaded Tee Installation

Accurate Pipe Cutting and Deburring

Precise pipe cutting and deburring are fundamental steps for a robust industrial piping system. Installers must use a fine-toothed saw or a dedicated PVC pipe cutter for clean, square cuts. Avoid tools that crush or deform pipe ends; these tools compromise joint integrity. Always measure and mark cutting points accurately. After cutting, remove all burrs or rough edges with a deburring tool or utility knife. Chamfer the outer edges slightly. This facilitates smooth entry into fittings and reduces the risk of damaging O-rings or sealing surfaces during assembly. Stabilizers ensure the PVC pipe maintains its structural integrity during cutting. They prevent the material from weakening or becoming brittle. A stabilized PVC pipe is easier to work with, whether performing dry-fit tests or applying primer and cement. This process ensures a watertight seal once the pipe is installed. Proper cuts prevent obstructions, ensuring uninterrupted fluid flow and process efficiency.

Thorough Surface Cleaning and Preparation

Thorough surface cleaning and preparation are equally critical for strong, leak-proof connections. After cutting and deburring, wipe loose soil and moisture from the fitting socket and pipe end with a clean, dry rag. This prevents slowing of curing and reduction of joint strength. Next, apply primer. Installers should use a primer conforming to ASTM F656. Apply primer first to the inside of the fitting socket, then to the outside of the pipe, and finally, to the inside of the fitting socket again. Ensure all surfaces become tacky. Primers like Weld-On PC-64 penetrate, soften, and remove the surface gloss of plastic pipe and fittings. They also clean grease, oil, and dirt from the bonding surfaces. This step prepares the surfaces for optimal adhesion with solvent cement.

Dry Fitting and Alignment Verification

Always perform a dry fit of the pipe and fitting before applying any cement. This crucial step verifies proper alignment and fit. The pipe should enter 1/3 to 2/3 of the socket depth. If the pipe bottoms with little interference, consider using extra solvent cement during the actual assembly. This ensures a snug fit. For a PVC Male Threaded Tee, ensure the threads align perfectly without forcing. Proper dry fitting prevents misalignment issues and ensures a smooth, secure connection. This meticulous verification process saves time and prevents costly rework.

Step-by-Step PVC Flange Installation

Installing PVC flanges correctly ensures a secure, leak-proof connection vital for industrial piping systems. Each step demands precision, from applying solvent cement to tightening bolts and placing gaskets. Following these guidelines meticulously guarantees system integrity and operational efficiency.

Applying Solvent Cement for Flange Connections

Applying solvent cement correctly creates a strong, permanent bond for PVC flange connections. First, choose the right applicator. An applicator that is too large can cause excess cement pooling, while one that is too small may not apply enough cement or primer in time. The applicator should be at least half the pipe’s diameter in width or length. Always ensure the chosen solvent cement is specifically formulated for PVC, CPVC, or ABS plastics, as well as varying pipe diameters and installation conditions. Using the wrong cement can lead to unsatisfactory results. Consider specifying pipe and fittings from a single manufacturer to ensure proper fit due to allowable dimensional tolerances, even if they meet ASTM standards.

The application process involves several critical steps:

- Chamfer the pipe: Leave a slight chamfer (10-15%) on the pipe edge. This prevents scraping cement off the fitting walls during insertion.

- Deburr the pipe: Smooth rough edges to prevent plastic pieces from breaking off and causing blockages.

- Dry-fit: Join the pipe and fitting without cement to ensure proper alignment and an interference fit. This is crucial for the chemical bond.

- Clean: Thoroughly clean both the pipe and fitting with an ABS, PVC, or CPVC cleaner. This removes dirt, debris, and oils, preparing surfaces for a strong weld.

- Apply Primer: Primer softens joint surfaces and cleans them. It is recommended for Schedule 40 PVC and Schedule 80 piping systems. For FlowGuard Gold and ChemDrain systems, one-step cements may be used without primer for certain sizes, but primer is required for larger ChemDrain systems (6″ and 8″). Apply primer to soften the pipe’s surface, making it more porous for a secure weld. Apply the first coat to the fitting, then the pipe, followed by a second coat on the fitting. For ABS pipes, use only cleaner, not primer.

- Apply Solvent Cement: Solvent cement should be applied while the primer is still wet. Once the primer is dry, apply a thin coat of solvent cement. Apply to the pipe first, then the fitting, and then to the pipe again. Avoid puddling, which can weaken the joint.

- Join Quickly: Insert the pipe into the fitting quickly, giving it a quarter turn and holding it firmly for at least 30 seconds. This ensures even cement spread and a leak-proof joint. Wipe off excess cement.

- Allow Time to Cure: Allow ample time for the cement to cure completely. Cure times vary based on humidity, material (PVC/ABS cure faster than CPVC), pipe size (larger diameters take longer), and temperature.

Correct Bolting and Torque Specifications

Correct bolting and torque specifications are paramount for a secure and leak-free flange connection. The mating dimensions and configurations for these PVC flanges conform to ANSI B 16.5, Class 150 flanges. The working pressure is specified as 150 psi water at 73.4°F. Applying the correct torque prevents over-tightening, which can damage the flange, or under-tightening, which can lead to leaks.

Use a torque wrench to achieve the precise force required. The following table outlines recommended torque values for various PVC flange sizes:

| Size (inches) | Bolt Circle Diameter (inches) | Bolts Required | Bolt Size (UNC x Length) | Torque (ft-lbs) |

|---|---|---|---|---|

| ½ | 2.37 | 4 | ½-13 x 1 ¾ | 15-20 |

| ¾ | 2.75 | 4 | ½-13 x 1 15/16 | 15-20 |

| 1 | 3.12 | 4 | ½-13 x 2 | 15-20 |

| 1¼ | 3.50 | 4 | ½-13 x 2 ¼ | 15-20 |

| 1½ | 3.87 | 4 | ½-13 x 2¾ | 15-20 |

| 2 | 4.75 | 4 | 5/8-11 x 3 | 20-30 |

| 2½ | 5.50 | 4 | 5/8-11 x 3¼ | 20-30 |

| 3 | 6.00 | 4 | 5/8-11 x 3 5/8 | 20-30 |

| 4 | 7.50 | 8 | 5/8-11 x 3¾ | 20-30 |

| 5 | 8.50 | 8 | ¾-10 x 6-3¾ | 25-35 |

| 6 | 9.50 | 8 | ¾-10 x 4 3/8 | 30-50 |

| 8 | 11.75 | 8 | ¾-10 x 4 3/8 | 30-50 |

| 10 | 14.25 | 12 | 7/8-9 x 4½ | 53-75 |

| 12 | 17.00 | 12 | 7/8-9 x 4 5/8 | 53-75 |

Tighten bolts in a star pattern to ensure even compression across the gasket. This prevents uneven stress distribution and potential leaks.

Gasket Selection and Proper Placement

Gasket selection and proper placement are critical for achieving a leak-proof seal in PVC flange connections. The gasket acts as a barrier, filling any minor irregularities between the flange faces. Choosing the right gasket material depends heavily on the specific industrial environment and the chemicals the system will transport.

Common gasket materials include EPDM and Viton gaskets, each offering distinct advantages. EPDM gaskets are excellent for keytones, hot and cold water, and alkalis. Viton gaskets provide superior chemical resistance for more aggressive substances.

Consider the following table when selecting a gasket for specific applications:

| Suitable for | EPDM | Natural rubber/SBR | Neoprene | Nitrile | Butyl | Silicone |

|---|---|---|---|---|---|---|

| Keytones | Yes | No | No | No | No | No |

| Hot & cold water | Yes | No | No | No | No | No |

| Alkalis | Yes | No | No | No | No | No |

| Acids & bases | No | Yes | No | Yes | No | No |

| Heat | Yes | No | No | Yes | No | No |

| Oils | No | No | No | Yes | No | No |

| Hot oils | No | No | No | Yes | No | No |

| Ozone | Yes | No | Yes | No | Yes | No |

| Weather resistance | Yes | No | Yes | No | Yes | No |

| Abrasion resistance | No | Yes | No | Yes | No | No |

| Low-moisture permeability | No | No | No | No | Yes | No |

| Low-gas permeability | No | No | Yes | No | Yes | No |

| Seawater applications | No | No | Yes | No | No | Yes |

| High temperatures | No | No | No | No | No | Yes |

| Low temperatures | No | No | No | No | No | Yes |

| Vibration suppression | No | No | No | No | No | Yes |

| General chemical resistance | No | No | No | No | Yes | No |

| Animal fats | No | No | No | Yes | No | No |

Always ensure the gasket is clean and free of debris before placement. Center the gasket precisely between the two flange faces. Misalignment can lead to uneven compression and potential leaks. Proper gasket selection and careful placement are crucial steps for long-term system reliability.

Step-by-Step PVC Male Threaded Tee Installation

Installing a PVC Male Threaded Tee requires careful attention to detail. Proper technique ensures a leak-free and durable connection. This section guides installers through thread preparation, correct tightening, and how to prevent common damage.

Thread Preparation and Sealing Techniques

Effective thread preparation and sealing are crucial for preventing leaks in threaded PVC connections. Installers must ensure threads are clean, dry, and free of debris. Two primary methods exist for sealing threads: PTFE tape and pipe dope.

For PTFE tape application, follow these steps:

- Prepare the Threads: Ensure male threads are clean, dry, and free of debris or old sealant.

- Start Correctly: Hold the tape end against the pipe just behind the first thread. Leave the very first thread bare for easier fitting starts.

- Wrap with Tension: Pull the tape taut. Wrap it in a clockwise direction (to the right). This ensures it tightens when the fitting screws on. Wrap tightly so the tape conforms to the thread shape.

- Overlap and End: Overlap each new wrap by 50%. For standard 1/2″ or 3/4″ pipes, apply 4 to 6 full wraps. Larger pipes (1″ and above) may need 7 or 8 wraps. Tear the tape and press the end firmly.

- Inspect Before Assembly: Verify that threads are fully covered with smooth, layered tape. Ensure no folds, wrinkles, or loose ends exist.

For pipe dope application, follow these steps:

- Preparation: Ensure threads are clean and dry.

- Application: Apply a moderate, even coat of plastic-safe pipe dope to the male threads only. Use a brush or stick. Cover all threads completely, but avoid globs. The thread shape should still be visible through the paste.

- Assembly: Hand-tighten the fitting. Then, use a wrench to turn it 1 to 2 full turns past hand-tight. Wipe away any excess paste.

Installers must avoid common mistakes. Never wrap tape counter-clockwise; this causes the tape to unwind. Too few wraps lead to insufficient gap filling. Too many wraps can prevent full tightening. Loose, sloppy wrapping creates voids and leak paths. Always start behind the first thread; covering it makes starting the fitting difficult. For critical applications, combine methods: apply 2-3 turns of PTFE tape first, then a thin layer of plastic-safe pipe dope over the tape for maximum reliability.

Proper Tightening for PVC Male Threaded Tee

Proper tightening of a PVC Male Threaded Tee ensures a secure, leak-free connection without causing damage. Installers should always begin by hand-tightening the fitting. This allows for proper alignment and prevents cross-threading. Once hand-tight, use a wrench to apply additional turns. For Schedule 40 or 80 PVC joints, tighten them finger tight plus one to two turns—no more. This method achieves a snug fit without excessive force.

Many professionals recommend a specific approach. They hand-tighten the fitting until it feels snug. Then, they use a tool to add one or two full turns. This technique provides a secure connection. It also minimizes the risk of overtightening. Installers should feel the resistance. They should stop tightening when the fitting feels firm and secure.

Avoiding Overtightening Damage to Threads

Overtightening PVC threads can cause significant damage. This includes stress fractures or completely splitting the fitting. Installers must recognize the signs of overtightening. They should also implement practices to prevent it.

Common signs of overtightening damage include:

- Cracked pipe

- Damaged threads

- Difficult disassembly later

- Potential leaks

Installers can avoid overtightening by following these guidelines:

- Tighten Schedule 40 or 80 PVC joints finger tight plus one to two turns—no more.

- Avoid using Teflon tape, Teflon paste, or pipe dope on plastic fittings. These can lubricate the joint, encouraging overtightening and adding strain/stress.

- Instead, use a non-hardening sealant. This sealant must be compatible with plastic. It should not add slipperiness. It must also be certified harmless to the fitting material and fluid.

- Apply Teflon tape (for male threads).

- Hand-tighten first.

- Continue to snug with firm hand pressure.

- Do not use excessive force.

- Verify a maximum engagement of 5/8″.

- For final snugging, wrenches should only be used after initial hand-tightening.

Feeling significant resistance or hearing a cracking sound during tightening signals damage. Visual indicators like warped or distorted threads also signal damage. Apply snug but moderate force. Ensure the fitting feels tight without excessive effort.

Best Practices for Leak Prevention

Preventing leaks in industrial PVC piping systems requires diligent adherence to best practices. These practices ensure the system’s long-term reliability and safety. Businesses must prioritize each step to achieve optimal performance.

Importance of Adequate Curing Time

Adequate curing time is paramount for strong, leak-proof PVC connections. Solvent cement creates a chemical bond between pipe and fitting. This bond needs sufficient time to fully develop its strength. Rushing the curing process compromises the joint’s integrity. It significantly increases the risk of leaks under pressure. Always consult the solvent cement manufacturer’s guidelines for specific curing times. These times vary based on temperature, humidity, and pipe diameter. Allowing proper curing ensures the system withstands operational demands.

Effective Pressure Testing Procedures

Effective pressure testing procedures identify potential leaks before system operation. This critical step verifies the integrity of all connections. Conduct pressure tests after the full curing period. Fill the system with water, then gradually increase pressure to the specified test level. Maintain this pressure for a designated duration, typically several hours. Carefully inspect all joints, flanges, and threaded connections for any signs of leakage. A successful pressure test confirms the system’s readiness for service. It prevents costly failures during active operation.

Regular Inspection Protocols for System Integrity

Regular inspection protocols maintain system integrity and prevent unexpected failures. Establish a routine inspection schedule to check for wear, leaks, or discoloration. This proactive approach identifies minor obstructions before they become major blockages. Comply with local, national, and international codes and regulations, such as ASME B31.3 for process piping and OSHA regulations for worker safety. Conduct regular external inspections periodically while piping is online, typically every 12-18 months for minor shutdowns or 24-36 months for major shutdowns. Pay special attention to supports, hangers, and joints during these external checks. Ensure plastic piping does not sag or bend. Integrate maintenance and inspection into a comprehensive Process Safety Management (PSM) program. Ensure all team members know and rigorously follow PSM safety guidelines. Perform internal inspections if external checks raise concerns. Utilize tools like borescopes or endoscopes for internal examinations. These tools detect misshapes, obstructions, or signs of wall thickness depletion. Visually inspect the piping system during commissioning and again after one year of service. This helps identify fabrication, installation, or operational issues. Implement protective measures like UV-resistant coatings or shading to mitigate UV light exposure.

Common Installation Challenges and Solutions

Even the most meticulous installations can encounter challenges. Addressing these issues promptly and effectively ensures the long-term integrity of industrial piping systems. Installers must understand common problems and their solutions to maintain system reliability.

Addressing Misalignment Issues Effectively

Misalignment during PVC piping installation can lead to significant stress and eventual leaks. Installers must carefully measure and mark all pipe sections before cutting. Dry fitting components together allows for early detection of alignment issues. If misalignment occurs, workers should adjust pipe lengths or fitting angles slightly. Never force misaligned components together; this creates internal stress points. Proper planning and precise execution prevent these common problems, ensuring a smooth, stress-free system.

Preventing Thread Stripping in PVC Male Threaded Tee

Preventing thread stripping in a PVC Male Threaded Tee requires careful technique. Always inspect threads for damage and clean debris to ensure proper engagement. Debris can hinder a smooth connection. Use thread sealant sparingly to avoid blockages and ensure threads engage correctly. Installers must tighten fittings firmly but not excessively to prevent thread stripping. Over-tightening applies undue stress, weakening the plastic. Use wrenches that match fitting sizes to avoid damage to the fitting itself. A correctly sized wrench provides better control and reduces the risk of applying uneven force.

Troubleshooting Minor Leaks Post-Installation

Even with careful installation, minor leaks can sometimes appear. Identifying these leaks quickly prevents further damage. A sudden decrease in water pressure often indicates a leak. Mold growth and a rotten smell, especially around visible PVC pipes, suggest a leak causing mold. Water stains or visible moisture on walls or floors point to hidden leaks. For detection, acoustic listening devices can detect high-frequency sounds from escaping water. Thermal imaging cameras identify temperature changes behind walls. Video pipe inspections use small cameras to look inside pipes for cracks. Pressure testing confirms water pressure levels and identifies drops. For repairs, rubber or silicone repair tape creates a compression seal for minor leaks. Epoxy putty forms a waterproof seal for small leaks. Fiberglass resin tape offers a strong, waterproof seal. For more robust fixes, consider PVC epoxy, PVC Lock Slide Repair Couplers, PVC flex coupling, or slip coupling.

Maintaining Your Industrial PVC Piping System

Maintaining industrial PVC piping systems ensures their long-term performance. Regular care prevents costly breakdowns. Businesses can achieve maximum operational efficiency with a proactive approach.

Routine Maintenance Checks for Longevity

Routine maintenance checks are vital for system longevity. Regularly inspect all visible piping for any signs of stress or damage. Look for leaks around flanges, threaded tees, and other connection points. Check pipe supports and hangers. Ensure they remain secure and provide adequate support. A consistent inspection schedule helps identify minor issues early. Addressing these small problems prevents them from becoming major failures. This proactive strategy extends the life of the entire system.

Identifying Wear and Tear Signs

Identifying wear and tear signs early is crucial. Look for discoloration, especially yellowing, which indicates UV degradation. Small cracks or hairline fractures on the pipe surface suggest material fatigue. Sagging pipes can point to inadequate support or excessive weight. Any changes in pipe alignment also require attention. Discolored or brittle gaskets around flanges signal a need for replacement. These visual cues help pinpoint potential problem areas. Early detection allows for timely intervention.

Repairing Damaged PVC Sections

Repairing damaged PVC sections promptly restores system integrity. Professionals first collect necessary repair materials. These include a sanitizing agent, PVC cement, sandpaper, PVC primer, and new PVC pipe pieces. They then inspect the pipe to diagnose the damage. This assessment determines the best repair strategy.

Site preparation involves thoroughly cleaning the compromised area. This removes impurities like mold or debris. Polishing smooths out any ragged edges of the fracture. This prevents voids during the joining process.

Several methods exist for mending pipe fractures:

- PVC Cement and Primer Method: This works well for low-pressure systems. Primer cleans the surface. Cement bonds and strengthens the pipe.

- Cut-and-Replace Method: For extensive damage, workers cut out the damaged section. They replace it with a new pipe piece. Cement and primer secure the new section.

- Slip Coupling Repair: This less invasive method involves cutting a short damaged section. A specially designed coupling slides over existing pipe ends. A new pipe piece then inserts and secures with PVC cement.

After repair, testing and analysis ensure plumbing system efficiency. This checks water flow and analyzes for unusual sounds.

Meticulous installation is crucial for leak-free industrial PVC systems. Businesses must prioritize accurate cutting, thorough cleaning, and precise solvent cement application. Correct bolting of flanges and proper sealing for PVC Male Threaded Tee connections ensure system integrity. Adhering to these steps and performing regular maintenance provides long-term reliability. This approach guarantees operational safety and extends the lifespan of industrial piping infrastructure.

FAQ

Why is proper installation of PVC flanges and male threaded tees important?

Proper installation prevents costly leaks. It ensures operational safety. It also extends system longevity. Meticulous work guarantees reliable industrial PVC piping systems.

What are the key benefits of using PVC in industrial applications?

PVC offers excellent chemical resistance. It is lightweight, simplifying installation. Its smooth interior promotes efficient fluid flow. PVC provides a cost-effective, long-lasting solution for diverse industrial settings.

How do installers prevent leaks in threaded PVC connections?

Installers prepare threads thoroughly. They use PTFE tape or plastic-safe pipe dope. They apply sealant correctly. They tighten fittings firmly but avoid overtightening. This ensures a secure, leak-free seal.

What is the importance of adequate curing time for solvent cement?

Adequate curing time allows the chemical bond to fully develop. Rushing this process compromises joint integrity. It significantly increases leak risk under pressure. Proper curing ensures the system withstands operational demands.

How do installers avoid overtightening PVC threads?

Installers hand-tighten first. They then use a wrench for one to two additional turns. They avoid excessive force. This prevents stress fractures or splitting the fitting. It ensures a secure connection without damage.

See Also

Essential Air Fryer Pan Accessories to Elevate Your Cooking Experience

Effortlessly Master Air Fryer Sausage Patties: Simple Recipes and Expert Advice

Top 5 Industrial Air Fryers Essential for High-Volume Kitchens

Simple Guide to Perfect Trader Joe’s Coconut Shrimp in Your Air Fryer

Effortless Steps to Replace Your PowerXL Air Fryer Basket Quickly