PPR Male Adaptors Explained A Guide to Threading and Integration

PPR male adaptors provide a crucial threaded interface. They connect PPR piping to metal systems. PPR pipes are widely adopted for hot and cold water distribution. Their thermal stability and chemical resistance make them popular. They are used in residential, commercial, and institutional construction projects.

These adaptors are essential in various settings:

- Residential Plumbing: They connect water supply lines in kitchens and bathrooms.

- Commercial Buildings: Hotels, offices, and schools use them for efficient water distribution.

- Heating Systems: They facilitate connections to metal components like radiators.

- Industrial Settings: They integrate PPR with diverse plumbing setups.

This guide details how to achieve reliable connections. It covers understanding thread standards and ensuring compatibility.

Key Takeaways

- PPR male adaptors connect plastic PPR pipes to metal plumbing parts. They are important for mixing different pipe systems.

- Understand pipe thread types like NPT and BSPT. They are different and do not work together. Using the wrong type causes leaks.

- Always check the thread type and size before you connect pipes. This stops leaks and damage.

- Use sealants like Teflon tape or liquid sealants. They fill small gaps and make sure the connection does not leak.

- Install PPR male adaptors correctly. Do not tighten them too much or too little. Test for leaks after installation to ensure safety.

Understanding PPR Male Adaptors

What is a PPR Male Adaptor?

A PPR Male Adaptor serves as a critical connector in plumbing systems. It features a PPR body on one end for fusion welding to a PPR pipe. The other end has external threads, allowing connection to metal fittings or components. These adaptors bridge the gap between plastic and metal piping. They ensure a secure and leak-proof transition.

PPR male adaptors are constructed from durable and heat-resistant PPR (Polypropylene Random Copolymer) material. This design withstands high temperatures and pressures for long-lasting performance. The metal components within the adaptor are also of high quality.

| Component | Raw Material |

|---|---|

| Plastic | Polypropylene Random Copolymer (PP Type 3) |

| Metal | Brass CW617N |

PPR male adaptors can feature inserts made from:

- Brass (including CW617 Brass)

- Iron

- Stainless steel

Why PPR Male Adaptors are Essential for Mixed Systems

Modern plumbing often combines different materials. PPR pipes offer advantages like corrosion resistance and thermal efficiency. However, many existing systems and fixtures use metal. PPR male adaptors become essential in these mixed systems. They allow seamless integration of PPR piping with metal valves, pumps, water heaters, and other threaded components. This capability ensures system flexibility and broad applicability. Without these adaptors, connecting PPR to metal would be complex and unreliable.

Key Features of Quality PPR Male Adaptors

Quality PPR male adaptors possess several important features. They offer robust construction, ensuring durability and resistance to wear. The PPR material provides excellent chemical resistance and withstands high temperatures and pressures. The threaded metal inserts, often made from brass, ensure strong, reliable connections to metal pipes. Donsen, for example, utilizes advanced production lines for PPR brass and plastic components, ensuring high-quality integration. Precision engineering of these threads prevents leaks and ensures compatibility with standard metal fittings. A well-designed PPR Male Adaptor provides a long service life and maintains system integrity.

Navigating Thread Standards for PPR Male Adaptors

Introduction to Pipe Thread Standards

Understanding pipe thread standards is crucial for creating secure and leak-free connections in plumbing systems. The evolution of these standards reflects a long history of industrial development and the need for reliable interfaces. Sir Joseph Whitworth introduced a unified thread system in 1841. This system became the first national standard for screw threads. It featured a 55-degree thread angle and rounded crests and roots. This innovation laid the foundation for British Standard Pipe (BSP) threads.

Engineers in the 19th century adapted Whitworth’s principles. They created BSP threads specifically for pipe connections. The British Standards Institution (BSI) formalized these threads in the early 1900s. BSP threads gained widespread adoption in Britain. Factories, railways, and shipyards used them extensively. This influenced other countries to adopt similar standards. The evolution involved continuous refinements in thread design. These refinements included tighter tolerances for better compatibility and enhanced sealing. BSP threads achieved widespread international acceptance. Organizations like ISO played a key role in aligning them with global standards. This facilitated international trade.

The evolution of thread standards, from Whitworth’s 1841 specification to the Unified inch standards and then to the ISO metric system, reflects the ongoing pursuit of industrial coherence. Each transition was driven by specific needs. Whitworth brought order during the Industrial Revolution. The Unified standard bridged allies during wartime. The ISO metric thread aimed for a global standard. However, this history has resulted in multiple coexisting standards. These standards continue to cause practical problems, including dangerous thread mismatches in critical applications.

During the Industrial Revolution, the need for reliable pipe connections became evident. This led to the introduction of tapered pipe threads. They could withstand high pressures and minimize leakage. These replaced less effective straight threads that relied on sealing materials. By the late 19th century, two major national standards emerged:

- NPT (National Pipe Taper) in the United States, defined by ANSI.

- BSPT (British Standard Pipe Taper) in the United Kingdom.

In the 20th century, Japan introduced PT (Pipe Taper) threads. BSPT largely influenced these threads. Japan incorporated them into its JIS framework.

BSPT (British Standard Pipe Taper) Threads

BSPT threads are a de facto standard for plumbing outside North America. They are commonly used in UK/Commonwealth plumbing. These threads are prevalent across Europe, Commonwealth countries (e.g., Australia, South Africa), Asia, and the Middle East. BSPT is the dominant standard in the United Kingdom, all of Europe, Asia, Australia, New Zealand, South Africa, and much of the Middle East.

BSPT threads are commonly used for fixed pipework. This includes main water lines in buildings. A permanent and durable seal is crucial in these applications. Galvanized pipe fittings with BSP threads are frequently found in water systems. Their corrosion resistance makes them suitable. BSPT fittings are used in plumbing and water supply for connecting pipes. They are found in potable water and drainage systems in residential and commercial buildings.

NPT (National Pipe Taper) Threads

NPT (National Pipe Taper) threads are the dominant standard in the United States and Canada. They are widely used in plumbing, construction, and industrial projects. This includes equipment manufactured in North America, such as hydraulic pumps and valves. NPT is also utilized in hydraulic and pneumatic systems, particularly for North American-made equipment. Its use in very high-pressure applications (above 6,000 PSI) is sometimes debated due to potential spiral leaks. Furthermore, NPT threads are extensively used in fire protection and safety equipment, especially in systems installed in the US, such as in New York. A PPR Male Adaptor designed for North American systems will typically feature NPT threads.

NPT threads have specific dimensions and thread angles.

- NPT threads have a 60° thread form.

- The taper rate is 0.75 inches per foot (1 in 16). This corresponds to a 1°47’ half angle.

- The taper rate for all NPT threads is 1⁄16 (3⁄4 inch per foot).

- The angle between the taper and the center axis of the pipe is 1° 47′′ 24″″ (1.7899°).

- The angle between the sides of the thread is 60 degrees.

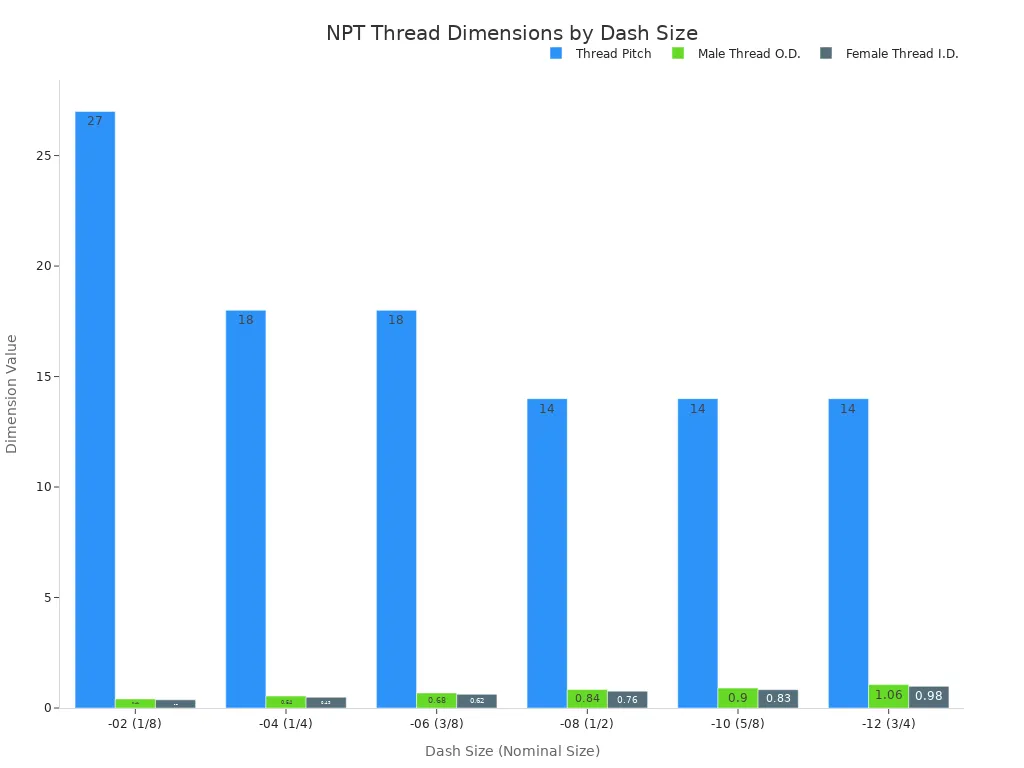

The following tables and charts illustrate typical NPT thread specifications:

| Dash Size (Nominal Size) | Thread Pitch | Male Thread O.D. inches | Female Thread I.D. inches |

|---|---|---|---|

| -02 (1/8) | 27 | 0.41 | 0.37 |

| -04 (1/4) | 18 | 0.54 | 0.49 |

| -06 (3/8) | 18 | 0.68 | 0.62 |

| -08 (1/2) | 14 | 0.84 | 0.76 |

| -10 (5/8) | 14 | 0.90 | 0.83 |

| -12 (3/4) | 14 | 1.06 | 0.98 |

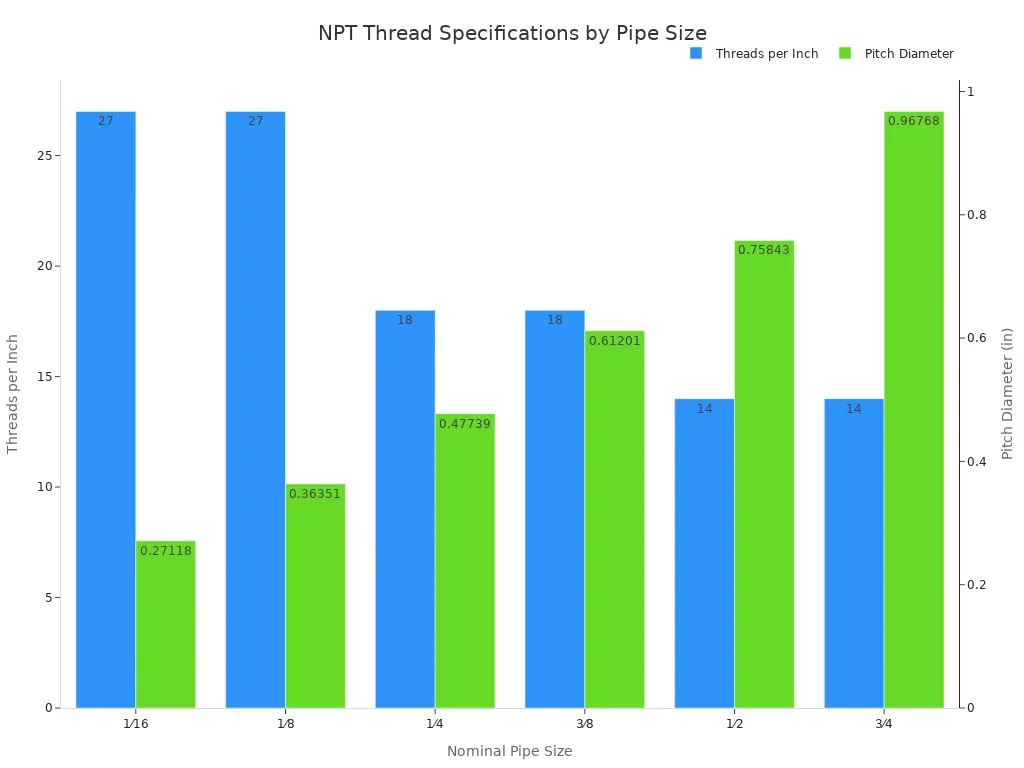

| Nominal Pipe Size | Threads per Inch | Pitch Diameter at External Thread Start E0 |

|---|---|---|

| 1⁄16 | 27 | 0.27118 |

| 1⁄8 | 27 | 0.36351 |

| 1⁄4 | 18 | 0.47739 |

| 3⁄8 | 18 | 0.61201 |

| 1⁄2 | 14 | 0.75843 |

| 3⁄4 | 14 | 0.96768 |

Key Differences Between BSPT and NPT Threads

Understanding the precise technical differences between BSPT and NPT threads is paramount for ensuring secure and leak-free plumbing connections. Although both are tapered pipe threads, they possess distinct characteristics that make them incompatible. Attempting to interchange them often leads to leaks or damaged fittings.

The primary distinctions lie in their thread angle, profile, and sealing mechanisms.

| Feature | NPT Threads | BSPT Threads |

|---|---|---|

| Thread Angle | 60 degrees | 55 degrees |

| Thread Profile | Flat crest and root | Rounded profile |

| Sealing Method | Relies on thread deformation and sealing compound | Primarily depends on thread profile and precision for sealing, often requiring less reliance on additional sealants |

| Compatibility | Incompatible with BSPT | Incompatible with NPT |

Both NPT and BSPT threads share a similar taper rate of 1 inch in 16. However, their differing thread angles and profiles mean the threads do not align correctly when mixed. NPT threads feature a 60-degree angle between the thread flanks and have flattened peaks and valleys. In contrast, BSPT threads have a 55-degree angle and a rounded profile for their crests and roots. This fundamental difference in geometry prevents proper engagement and sealing.

| Feature | NPT Threads | BSPT Threads |

|---|---|---|

| Thread Angle | 60 degrees | 55 degrees |

| Thread Shape | Flattened peaks and valleys | Rounded peaks and valleys |

| Thread Pitch | Each size has a specific TPI | Each size has a specific TPI |

| Taper Rate | 1 inch in 16 | 1 inch in 16 |

The sealing method also varies. NPT threads achieve a seal through the deformation of the threads as they tighten, typically requiring a thread sealant like Teflon tape or pipe dope to fill the gaps. BSPT threads, while also tapered, rely more on the precision of their thread profile for sealing, though sealants are still commonly used.

Identifying Thread Types for PPR Male Adaptor Connections

Correctly identifying the thread type of an existing pipe or fitting is a critical step before selecting a PPR Male Adaptor. Mismatched threads lead to leaks, system failure, and potential damage to components. Professionals follow a systematic approach to ensure accurate identification.

Here are the recommended steps for identifying thread types:

- Determine if the thread is tapered or parallel:

- Visually inspect the thread. Tapered threads narrow towards the end, while parallel threads maintain a consistent diameter.

- Use the parallel jaws of a caliper. If the caliper touches the entire length, the thread is parallel. If it rocks, the thread is tapered.

- The presence of an O-ring or the removal of a tube nut often indicates a parallel male thread.

- NPT (National Pipe Tapered) threads narrow as they extend. NPS (National Pipe Straight) threads maintain a consistent diameter. Straight fittings require an O-ring or gasket for sealing. Tapered fittings use Teflon tape or pipe sealant.

- Determine the pitch:

- Use a pitch gauge for comparison. A pitch gauge has various teeth patterns. Match the gauge to the threads.

- Measure and calculate the number of threads over a specific distance.

- Using a lighted background with a pitch gauge is recommended for better visibility.

- Try multiple gauges. Some pitches are very similar.

- Determine the size:

- Combine the results from the previous steps.

- For pipe threads (like NPT/NPTF, BSPT, BSPP), compare the size to a nominal size profile. For sizes up to 2 inches, measure the actual outside diameter, subtract ¼ inch, then round off to find the nominal size.

- For non-pipe threads (UN/UNF, Metric Parallel, Metric Tapered), measure the outside diameter (major diameter) with a caliper.

- Use a caliper, measuring tape, or ruler to measure the inner diameter (ID) of female threads and the outer diameter (OD) of male threads. Match this measurement to a thread chart to find the nominal size. Thread dimensions are based on the pipe’s ID, not standard units.

By following these precise identification methods, installers can confidently select the correct PPR Male Adaptor. This ensures a compatible and reliable connection between PPR piping and metal systems.

Ensuring Compatibility with PPR Male Adaptors

Ensuring compatibility between PPR piping and metal components is paramount for a reliable plumbing system. Installers must correctly select thread specifications. This prevents leaks and ensures the long-term integrity of the connection.

The Dangers of Mismatched Threads

Connecting mismatched pipe threads poses significant risks. These risks can lead to system failures and costly repairs. A common issue is leakage. This occurs when parallel BSPP and tapered BSPT threads do not match. Over-tightening can damage threads, while under-tightening fails to create a sufficient seal. Both scenarios result in fluid or gas escaping.

Mismatched threads also cause thread damage. This damage happens during installation, disassembly, or use. Incorrect tools or excessive force can strip or deform threads. Corrosion in harsh environments can also erode threads, weakening the connection over time. In industrial settings, vibration-induced loosening can occur. Vibrations from machinery or fluid flow cause mismatched connections to loosen. This leads to leaks and safety hazards. Furthermore, material incompatibility can cause problems. Using different metals in contact with an electrolyte leads to galvanic corrosion. This weakens the connection and causes premature failure.

Using the wrong thread type is like trying to fit a square peg into a round hole. The connection might seem to start, but it will never seal properly and is likely to fail under pressure. Imagine a technician in Dubai working on a cooling system imported from the United States that uses NPT fittings. He tries to screw a locally available BSPT gauge into the NPT valve. It engages for one or two turns and then binds. Applying more force with a wrench causes the softer brass threads of the gauge to strip, or worse, the cast iron valve body cracks. This renders the system inoperable and necessitates a costly repair. This scenario underscores the absolute necessity of correctly identifying and matching thread types before attempting a connection to prevent costly errors.

The long-term consequences of using mismatched threads are severe. They include:

- Catastrophic failure risk: NPT fittings over-tightened or IPS pipes not rated for high-pressure applications risk catastrophic failure.

- Installation delays: Mismatched pipe specifications frequently cause installation delays. They require new materials, adapters, or workarounds that increase leak risks.

- Maintenance challenges: Incorrect pipe types lead to misalignment issues and leaks from improperly sealed joints. They also cause incompatibility with older infrastructure. This increases repair frequency and requires extensive retrofits.

- System inefficiencies: Mismatched components cause pressure imbalances, corrosion, and increased wear on fittings. They also lead to overall system failures, resulting in long-term inefficiencies.

- Hidden corrosion risks: Mixing different metal types, such as galvanized steel IPS pipes with brass NPT fittings, can lead to electrolysis. This accelerates corrosion, weakens metal, and causes leaks or pipe failures.

- Financial impact: Incorrect pipe selection results in unplanned expenses. These include water loss from leaks, increased operational costs due to pressure loss, and higher labor costs for unexpected retrofits.

NPT and BSP fittings are not directly compatible due to differences in thread angle and design. Attempting to connect these two thread types leads to leaks and potential system failures. For example, using an NPT fitting with a BSP threaded pipe results in a poor fit. The threads will not engage properly, compromising system integrity.

How to Select the Correct PPR Male Adaptor

Selecting the correct PPR Male Adaptor is crucial for a reliable connection between PPR and metal pipes. Installers must first accurately identify the thread type of the existing metal component. This involves determining if the thread is NPT (National Pipe Taper) or BSPT (British Standard Pipe Taper), as discussed in the previous section. Once the thread type is known, choose a PPR Male Adaptor with the corresponding thread standard.

Next, match the nominal size. Pipe threads are typically identified by their nominal pipe size (e.g., 1/2 inch, 3/4 inch), not their actual measured diameter. Refer to thread charts to confirm the correct nominal size for both the metal component and the PPR Male Adaptor.

Finally, prioritize quality. A high-quality PPR Male Adaptor features robust construction. Donsen, for instance, utilizes advanced production lines for PPR brass and plastic components. This ensures precise threading and durable materials. Such adaptors provide a secure, leak-free connection and withstand the demands of various plumbing systems.

Common Compatibility Scenarios for PPR Male Adaptors

PPR Male Adaptors facilitate connections in numerous plumbing scenarios. They reliably connect PPR pipes to metal systems.

- Connecting to Metal Valves: Installers frequently use PPR Male Adaptors to connect PPR lines to metal ball valves, gate valves, or check valves. This allows for control and isolation within the PPR system.

- Integrating with Water Heaters: Water heaters often have metal threaded inlets and outlets. A PPR Male Adaptor provides a seamless transition from the PPR supply lines to the heater.

- Linking to Pumps: Pumps in heating or water supply systems typically feature metal threaded ports. PPR Male Adaptors ensure a secure connection between the PPR piping and the pump.

- Transitioning to Existing Metal Lines: In renovation projects, PPR Male Adaptors allow for easy integration of new PPR piping with existing galvanized steel, copper, or brass lines. This ensures system continuity.

- Connecting to Fixtures: Many plumbing fixtures, such as pressure gauges or expansion tanks, have metal threaded connections. PPR Male Adaptors enable the PPR system to interface with these components effectively.

In all these scenarios, proper thread identification and the use of appropriate sealing materials, like PTFE tape or pipe dope, are essential for a durable and leak-free connection.

Role of Sealants and Tapes with PPR Male Adaptors

Threaded connections, especially those involving a PPR Male Adaptor and metal components, require effective sealing to prevent leaks. Sealants and tapes fill microscopic gaps between threads. They create a watertight and airtight barrier. Choosing the correct sealant depends on the application, material, and pressure requirements.

Various types of thread sealants and tapes are available for plumbing applications. Each type offers specific properties.

| Sealant Type | Properties |

|---|---|

| Liquid Thread Sealant | Not solvent-based, takes time to cure, does not crack or shrink, creates tight air/water-proof seal, often PTFE-based, easy to apply, resistant to high temperatures, pressure, vibration, and chemicals. Can be used as a high-temperature and high-pressure sealant. Has a longer curing period but doesn’t crack or shrink. Most cost-effective given its wide range of material, temperature, and pressure suitability. |

| PTFE Sealing Tape (Teflon Tape/Plumbers’ Tape) | White, non-sticking, acts as a filler, makes tightening easier, prone to tear and can clog the system if not installed carefully. Standard quality performs from -200°C to +260°C. Easiest installation. Prone to tear during installation and can enter the system and clog it. Quick assembly and usage. Most economical option. |

| Pipe Dope | Good for metal connections, provides a more substantial seal than Teflon tape. Works well with wicking. |

| Wicking | String-like material, works well with pipe dope, enters smallest gaps for additional barrier against leaks. Particularly effective for older or problematic fittings. |

PTFE sealing tape, commonly known as Teflon tape or plumbers’ tape, is a popular choice. It is non-sticking and acts as a filler. This tape makes tightening easier. Installers must apply it carefully. It can tear and potentially clog the system if not installed correctly. Standard quality PTFE tape performs well across a wide temperature range, from -200°C to +260°C. Its installation is typically the easiest option. Despite its ease of use, it remains prone to tearing during installation. This can lead to small pieces entering and clogging the system. However, it offers quick assembly and usage. It is also the most economical option for sealing threaded connections.

PTFE tape comes in various colors, each indicating a specific use or property.

| Color of PTFE Tape | Specific Use/Properties |

|---|---|

| White | Standard/Premium, all-rounder for basic plumbing, robust, temperature-resistant, chemical-resistant, tightly seals threaded pipe connections. |

| Yellow | Designed for gas lines (natural gas, butane, propane), safe for gas applications. |

| Pink | Specifically for water lines, highly durable compared to standard types. |

| Grey or Silver | For stainless steel threads, high-density rating, twice as thick as standard seal tape. |

| Green | For oxygen lines, grease-free and oil-free, prevents fires. |

Liquid thread sealants offer another robust solution. These sealants are not solvent-based. They require time to cure. Once cured, they do not crack or shrink. They create a tight, air and waterproof seal. Often, these sealants are PTFE-based. They are easy to apply. They resist high temperatures, pressure, vibration, and chemicals. Liquid sealants can function as high-temperature and high-pressure sealants. Their longer curing period ensures a durable seal. They do not crack or shrink over time. Given their wide range of material, temperature, and pressure suitability, they are often the most cost-effective choice in the long run.

Pipe dope, a traditional sealant, works well for metal connections. It provides a more substantial seal than Teflon tape. Installers often use it with wicking. Wicking is a string-like material. It works effectively with pipe dope. It enters the smallest gaps. This creates an additional barrier against leaks. Particularly effective for older or problematic fittings.

Proper application of these sealants is crucial. Installers must clean the threads thoroughly before applying any sealant. For PTFE tape, they wrap it clockwise around the male threads, ensuring it lies flat and covers all threads. For liquid sealants or pipe dope, they apply a consistent bead or layer to the male threads. This ensures complete coverage. Correct sealant application guarantees a durable, leak-free connection between the PPR Male Adaptor and the metal system.

Installation Best Practices for PPR Male Adaptors

Preparation Steps for PPR Male Adaptor Installation

Proper preparation ensures a successful and leak-free installation. Installers begin by gathering essential tools. These include a PPR pipe cutter for clean, square cuts, and a deburring tool to remove sharp edges. A measuring tape and marker ensure accurate pipe length. For the fusion process, a PPR fusion welder with heating elements and clamps is necessary. Safety equipment, such as safety glasses and heat-resistant gloves, protects workers.

Next, technicians prepare the pipe and fitting surfaces. They cut the PPR pipe to the required length, ensuring a clean, square cut. They remove any burrs or sharp edges from the cut end using a utility knife or file. Workers then thoroughly clean the surfaces of both the PPR pipe and the metal fitting. This eliminates dirt, grease, or moisture. Some applications may require a thin layer of PPR primer on pipe ends and inside the fitting to enhance bonding. After priming, they allow it to dry as per manufacturer instructions.

Proper Thread Engagement for PPR Male Adaptors

Correct thread engagement is vital for a secure connection. For BSP tapered threads, installers ensure 4-6 full thread engagements. Similarly, NPT threads also require 4-6 full thread engagements. A general rule for tapered pipe threads, both metal and plastic, involves tightening the connection finger-tight, then adding one to two turns with a wrench. For NPT and NPTF fittings smaller than 1 inch, the wrench-tight engagement point typically ranges from 1-1/2 to 3 turns. Larger NPT and NPTF fittings, from 1 inch to 2 inches, usually require about 1 to 2-1/2 turns with a wrench. This precise engagement prevents leaks and maintains system integrity.

Avoiding Over-tightening and Under-tightening PPR Male Adaptors

Both over-tightening and under-tightening connections can lead to significant problems. Under-tightening results in insufficient thread engagement, causing leaks. The connection lacks the necessary compression to form a watertight seal. Conversely, over-tightening can strip threads, especially on plastic components or softer metals. This damages the fitting permanently. It compromises the seal and necessitates replacement. Excessive force can also crack the fitting body or deform the pipe. Installers must apply the correct torque. They follow manufacturer guidelines and the recommended thread engagement practices. This balance ensures a durable, leak-free connection.

Leak Testing Procedures for PPR Male Adaptor Connections

After installing PPR male adaptors, thorough leak testing ensures the integrity of the plumbing system. This critical step prevents costly damage and ensures operational safety. Installers typically employ two primary methods: visual inspection and pressure testing.

First, conduct a visual inspection. Examine all newly installed connections for any visible signs of moisture or drips. This initial check can often reveal obvious issues before applying pressure. Ensure all joints appear clean and properly sealed.

Next, perform a pressure test. This method involves introducing a controlled amount of pressure into the system. It then monitors for any pressure drops.

- Prepare the System: Close all outlets and valves in the section undergoing testing. Fill the system with water, ensuring no air pockets remain.

- Connect the Pressure Gauge: Attach a calibrated pressure gauge to a convenient point in the system.

- Apply Pressure: Use a hand pump or a pressure testing machine to gradually increase the pressure to the desired level. Consult local plumbing codes or manufacturer specifications for the appropriate test pressure. Typically, this is 1.5 times the system’s operating pressure.

- Monitor for Leaks: Maintain the test pressure for a specified duration, usually 30 minutes to several hours. Observe the pressure gauge for any drops. A consistent pressure drop indicates a leak.

- Locate Leaks: If the pressure drops, carefully inspect all connections, especially the PPR male adaptors. Apply a soap solution to the joints. Bubbles will form at the leak source.

- Address Leaks: If a leak is found, depressurize the system. Tighten the connection if under-tightening caused the leak. If the threads are damaged or mismatched, replace the adaptor or fitting. Re-test the system after making repairs.

Note: Always follow safety guidelines during pressure testing. Wear appropriate personal protective equipment. Never exceed the recommended test pressure for the piping system.

Successful leak testing confirms the reliability of PPR male adaptor connections. It provides confidence in the system’s long-term performance.

Troubleshooting Common Issues with PPR Male Adaptors

Dealing with Leaks in PPR Male Adaptor Connections

Leaks represent a frequent challenge in PPR male adaptor connections. They often stem from improper welding or inadequate sealing during installation. Several factors contribute to these issues. Incorrect heating temperature during fusion can lead to incomplete fusion. This creates weak joints prone to leaks. Inadequate heating or cooling time also causes problems. Removing pipes too soon prevents full merging. Excessive heating warps pipes. Improper alignment of pipes and fittings creates internal stress. This leads to premature wear or leaks. Failure to clean and prepare surfaces properly prevents bonding. Dirt, dust, oil, or moisture weaken the joint. Incorrect pipe cutting and deburring create stress points. Ignoring thermal expansion allowances causes buckling or cracking. Incorrect use of fusion tools results in weak joints. Poor support and pipe anchoring create stress at connection points. Neglecting pressure testing after installation means undetected leaks.

When a leak occurs, technicians inspect the joint for visible cracks or gaps. If improper welding caused the leak, they cut out the faulty section. Then, they re-weld it using correct techniques. Applying a suitable pipe sealant ensures a watertight seal. They ensure clean and dry pipe ends before application.

Addressing Stripped Threads on PPR Male Adaptors

Stripped threads on PPR male adaptors compromise connection integrity. Over-tightening is a primary cause. It damages the threads, especially on plastic components or softer metal inserts. Mismatched threads also contribute to stripping. For example, forcing an NPT fitting into a BSPT thread can strip the softer material. When threads strip, the connection loses its ability to seal. Technicians must replace the damaged adaptor or fitting. They avoid re-threading stripped components. Proper torque application during installation prevents this issue.

Preventing Corrosion When Using PPR Male Adaptors

Preventing corrosion is crucial for the longevity of PPR male adaptor connections. Galvanic corrosion occurs when two different metals contact each other. This happens in the presence of an electrolyte, such as water. To prevent galvanic corrosion, technicians use dielectric unions. They also use insulating materials between PPR male adaptors and metal pipes. This separates the dissimilar metals. Proper installation techniques are also important. They ensure a tight seal. They avoid sharp bends. These practices prevent leaks and ensure connection longevity.

Successfully connecting PPR pipes to metal systems relies on understanding and correctly applying thread standards. Installers must master BSPT and NPT specifications. Ensuring compatibility and following proper installation techniques are crucial. These steps lead to durable, leak-free connections. Professionals can integrate PPR effectively into diverse plumbing infrastructures with confidence.

FAQ

What is the main purpose of a PPR male adaptor?

A PPR male adaptor connects PPR pipes to metal components. It provides a threaded interface. This allows for seamless integration between plastic and metal plumbing systems.

Can installers mix NPT and BSPT threads?

No, installers cannot mix NPT and BSPT threads. They have different thread angles and profiles. Mixing them causes leaks and damages fittings. Always match the thread types for a secure connection.

Why are sealants important for PPR male adaptor connections?

Sealants fill microscopic gaps between threads. They create a watertight and airtight barrier. This prevents leaks and ensures the connection’s long-term integrity. PTFE tape and liquid sealants are common choices.

What happens if installers over-tighten a PPR male adaptor?

Over-tightening a PPR male adaptor strips threads. This damages the fitting permanently. It compromises the seal. Excessive force can also crack the fitting body or deform the pipe.

What materials make up quality PPR male adaptors?

Quality PPR male adaptors use durable PPR for the body. They feature threaded metal inserts, often made from brass. This robust construction ensures longevity and resistance to high temperatures and pressures.

See Also

Essential Air Fryer Pan Accessories: Elevate Your Cooking Experience Today

Air Frying Frozen Egg Rolls: Simple Guide for Perfect Crispy Results

Perfect Air Fryer Sausage Patties: Simple Recipes and Expert Cooking Tips

Effortlessly Cook Boneless Pork Ribs in Your Air Fryer: A Quick Guide

Trader Joe’s Coconut Shrimp: Simple Air Fryer Steps for Delicious Results