PP Compression Fittings and Plastic Valves Optimizing Irrigation in 2026

PP Compression Fitting for irrigation and plastic valves are essential for optimizing agricultural irrigation. They provide durable, leak-proof, and cost-effective solutions. The global market for agricultural irrigation systems reached 10.72 USD Billion in 2024, highlighting the industry’s scale. Agriculture uses 70 percent of global freshwater withdrawals. Efficient Agricultural irrigation pipe systems are vital for water conservation. A reliable HDPE pipe fittings supplier contributes to these advanced systems. These components ensure precise water distribution, thereby significantly enhancing efficiency and sustainability in modern farming practices.

Key Takeaways

- PP compression fittings and plastic valves are important for modern farm irrigation. They help save water and make farming better.

- PP compression fittings connect pipes tightly. They stop water leaks and are easy to put together without special tools.

- Plastic valves control water flow exactly. They help plants get the right amount of water and work well with smart farm technology.

- Using both PP fittings and plastic valves together makes strong irrigation systems. These systems reduce water waste and help crops grow better.

- DONSEN has much experience in making plastic pipes and valves. They offer many products and have good quality checks for irrigation needs.

The Imperative for Efficient Agricultural Irrigation

Global Water Scarcity and Farming Demands

Global water scarcity presents a significant challenge to agricultural production. By 2025, two-thirds of the world’s population may face water shortages. This situation will significantly impact global food security and agricultural efficiency. Several key drivers intensify water scarcity in agriculture. These include climate variability, such as prolonged droughts and erratic monsoons. A rising global population also contributes to the problem. Unsustainable management practices, like over-extraction of groundwater and improper irrigation, further exacerbate the issue. Land degradation and limited infrastructure also play a role.

Regions particularly affected by agricultural water scarcity include South Asia, Sub-Saharan Africa, the Middle East and North Africa, and parts of North America. Water scarcity leads to productivity decline in staple crops such as wheat, rice, and maize. This causes yields to drop and farmer incomes to decrease. It also contributes to poverty and social instability, especially for smallholder farmers. This can trigger social unrest and rural-to-urban migration. Nutrition and health suffer as farmers shift to less water-intensive but less nutritious crops. This increases malnutrition risks and aggravates global hunger due to food price spikes. Global markets experience disruptions, with shortages and competition for water driving up input costs. This threatens the stability of food trade networks. Under climate change, global agricultural water scarcity is predicted to worsen in up to 84% of croplands. A loss of water supplies drives scarcity in about 60% of those croplands. If greenhouse gas emissions continue to rise, this intensification is projected for 84% of cropland from 2026 to 2050.

Agriculture accounts for approximately 72% of global freshwater withdrawals. Sixty-six countries allocate over 75% of their total freshwater withdrawal to agriculture. Countries like Afghanistan, Mali, Nepal, and Sudan use 95% of their freshwater for agriculture. In Western Asia, rapid population growth and agricultural demand intensify pressure on limited water supplies. Countries such as Bahrain, Egypt, and Saudi Arabia have over 90% of their cultivated land equipped with irrigation infrastructure. Agriculture consumes nearly 70% of global freshwater withdrawals, leading to escalating pressure on reliable water supplies due to increasing water scarcity and climate change. Sixty percent of the world’s irrigated agriculture, particularly for crops like sugarcane, wheat, rice, and maize, already faces extremely high water stress. To feed an estimated 10 billion people by 2050, global food calorie production needs to increase by 56% compared to 2010 levels. This further strains water resources.

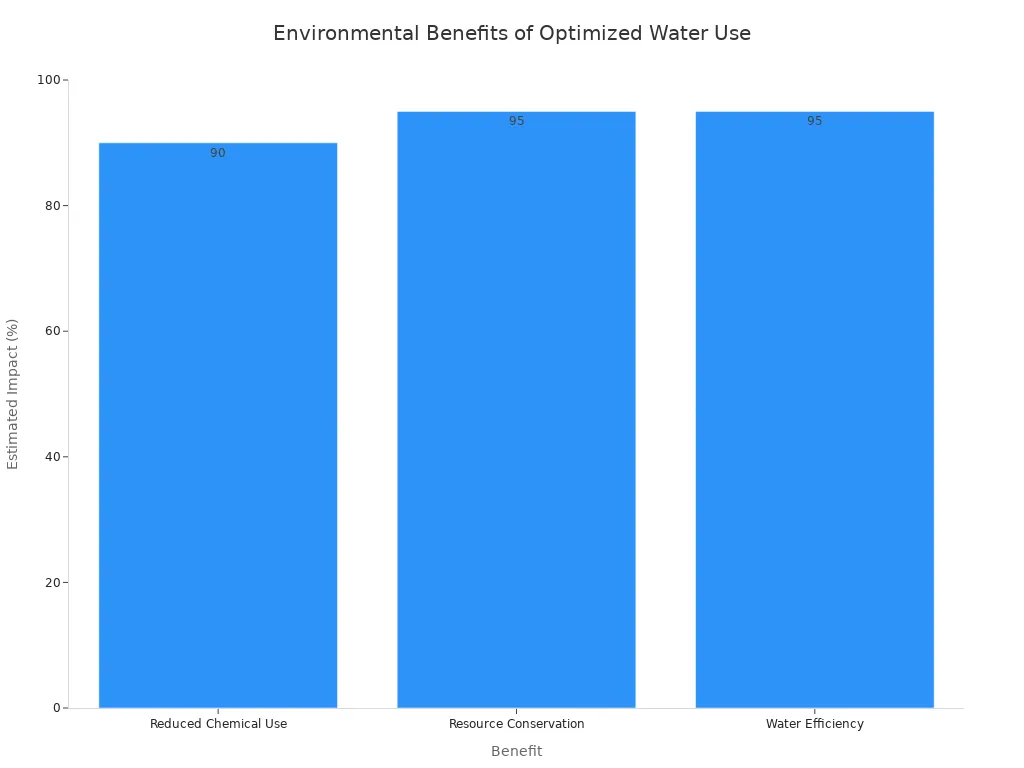

Economic and Environmental Benefits of Optimized Water Use

Optimized agricultural water use offers significant economic and environmental benefits. These practices lead to reduced chemical use, resource conservation, and improved water efficiency.

| Benefit | Description | Estimated Impact/Value |

|---|---|---|

| Reduced Chemical Use | Avoids synthetic fertilizers/pesticides, less chemical runoff and pollution | Reduces chemical pesticide use by up to 90% |

| Resource Conservation | Efficient use of water, energy, and nutrients, especially in CEA | Water usage lowered by approximately 30–95% |

| Water Efficiency | Uses advanced irrigation and recycling to save water | Improves water-use efficiency by up to 95% |

Optimized water use significantly reduces environmental impact.

“Controlled environment agriculture uses up to 95% less water than traditional farming, conserving vital natural resources.” Sustainable and organic farms help keep rivers and waterways cleaner. They limit runoff from fertilizers and pesticides. Hydroponics and aquaponics offer soilless, high-yield systems. These systems further conserve water and avoid problems of contaminated agricultural land. Aquaponics promotes a closed-loop symbiosis between aquatic animals and plants.

Alternative Furrow Irrigation (Alt.FI), Deficit Irrigation (DI), and Surface Irrigation with Mulch (SIM) are highly regarded for their cost-effectiveness. They require low infrastructure, decreased energy usage, and minimal maintenance expenses. These methods eliminate the need for intricate systems like pumps, pipelines, or pressurized setups. This greatly reduces both initial investment and ongoing costs. For example, Alt.FI functions by watering every other furrow, naturally halving water and energy consumption. DI intentionally restricts water during less critical growth phases of crops. SIM minimizes evaporation and runoff, resulting in fewer irrigation cycles. Drip irrigation is a water-efficient technology. It supplies water directly to the roots of plants, minimizing waste and enhancing crop production. Adopting drip irrigation can result in crop yield improvements between 3.6% and 66.4%. It also increases water use efficiency (WUE) by 5.9–60.0%.

Understanding PP Compression Fitting for Irrigation

What are PP Compression Fittings?

PP compression fittings are essential components in modern irrigation systems. They connect pipes and ensure a secure, leak-proof seal. These fittings are made from polypropylene (PP), a tough and versatile thermoplastic. Manufacturers choose polypropylene for its excellent chemical resistance, durability, and affordability. The manufacturing process begins with selecting high-quality polypropylene resin. Workers then heat this resin and inject it into molds, forming the specific shapes of the fittings. After injection, the molten PP cools and solidifies within the mold. Trimming and finishing remove any excess material, and inspectors carefully examine the fittings. Quality control checks ensure the fittings meet industry standards. Finally, finished fittings are packaged for distribution. The compression ring, a crucial part of the fitting, often consists of a soft, resilient material like rubber or EPDM. This material deforms to create a watertight seal. PP fittings are primarily used in systems requiring high heat tolerance and excellent chemical resistance.

Key Advantages for Agricultural Irrigation Systems

PP compression fittings offer numerous benefits for agricultural irrigation systems. Their robust construction ensures long-term reliability in demanding outdoor environments. These fittings provide a strong, leak-proof connection, which is crucial for efficient water delivery. They are also easy to install, often requiring no special tools or welding. This simplifies system setup and maintenance. PP compression fittings are primarily designed for cold water applications, including irrigation. They handle a working pressure of 1.6 Mpa and operate effectively in temperatures ranging from -40°C to 40°C. This gives them a pressure rating of 16 KG PRESSURE. However, for temperatures exceeding 73.4°F (23°C) or pressures above the stated maximum PSI, metal insert fittings are recommended. Farmers must also protect these fittings from freezing temperatures to prevent damage from fluid expansion.

The economic advantages of using PP compression fittings are significant. They are generally more cost-effective than traditional metal fittings. This reduces initial investment costs for irrigation infrastructure. Furthermore, irrigation systems utilizing PP saddle clamps have shown up to 30% greater water savings compared to conventional irrigation methods. This directly translates to significant cost reductions in agricultural irrigation due to decreased water usage. Their resistance to corrosion and chemicals also means a longer lifespan and reduced need for replacements, saving both time and money.

Applications Across Various Irrigation Systems

PP compression fittings find widespread application across different agricultural irrigation systems. They are particularly vital in drip irrigation setups, where precise water delivery is paramount. In these systems, PP compression fittings connect pipes, ensuring water reaches plant roots efficiently. For example, couplings connect different pipe sections. Reducing Tees branch the water flow, allowing for customized distribution layouts. Female Adaptors, including clamp saddles, connect to other components or pipes, providing flexibility in system design.

Agricultural irrigation projects frequently use PP compression fittings within drip irrigation systems. They are specifically designed to pair with PE pipes, forming essential connections for water distribution. This combination creates a reliable and adaptable network for delivering water directly to crops. Their versatility allows farmers to build robust and adaptable irrigation networks, optimizing water use and improving crop yields. The ease of installation and maintenance makes them a preferred choice for farmers seeking efficient and sustainable irrigation solutions.

The Role of Plastic Valves in Water Flow Control

Types of Plastic Valves for Agricultural Use

Plastic valves are indispensable components in agricultural irrigation systems. They offer precise control over water flow. Various types of plastic valves serve different functions within these networks. Common plastic valves include PVC Ball Valves, PVC Gate Valves, PVC Check Valves, PVC Foot Valves, PVC Globe Valves, PVC Butterfly Valves, 3-Way PVC Valves, and PVC Diaphragm Valves. Each type features a unique design and operational mechanism tailored for specific irrigation needs.

PVC Ball Valves are widely used in fluid control systems, including plumbing and irrigation. They operate with a rotating ball to control fluid flow. These valves offer quick quarter-turn operation for opening or closing. They are durable, resistant to corrosion and chemicals, and provide a cost-effective alternative to metal valves. Farmers commonly find them in irrigation systems, swimming pools, aquariums, chemical processing, and water treatment plants. PVC Ball Valves are extensively used due to their excellent sealing performance and quick shut-off capabilities. They appear in household water supply, gardening systems, swimming pool equipment, and low-pressure industrial pipelines. These valves feature a full-bore design that minimizes flow resistance. Their smooth-operating handles and easy maintenance make them practical components in many fluid control setups.

PVC Butterfly Valves are compact and easy-to-operate devices. They are ideal for on/off regulation in large-diameter piping systems. Their lightweight, corrosion-resistant bodies make them particularly suitable for agricultural irrigation, water treatment systems, and light industrial chemical pipelines. They allow for quick opening and closing, along with moderate flow regulation. This makes them excellent for handling large volumes of media. Other types like PVC Ball Check Valves prevent backflow. They offer reliable one-way flow using a ball mechanism that closes automatically under gravity or reverse pressure. Farmers frequently use them at pump outlets, drainage systems, and rainwater pipelines. PVC Wafer Check Valves offer a compact design for limited space installations. They suit both vertical and horizontal mounting, using a spring or gravity mechanism for one-way flow and backflow prevention.

Polypropylene (PP) is a common material for these valves. It is a thermoplastic polymer made from propylene monomers. PP is lightweight, durable, and exhibits excellent chemical resistance. This includes resistance to a wide range of acids, bases, and solvents. PP is commonly used for water and wastewater systems, as well as in chemical and industrial applications requiring corrosion resistance and low-cost materials. PPR ball valves, for instance, tolerate temperature fluctuations across seasons. Their materials expand and contract within safe limits without cracking or stress. They are reliable during frequent system startups, supporting repeated activation without component loosening or seal compression. PPR ball valves maintain their structure near fertilizer or compost areas, resisting environmental effects, chemical breakdown, and weakening from organic fumes or acids. They show no corrosion near moisture-heavy soil, remaining stable in wet zones, with no seepage, and maintaining tight contact of threads and seals.

Benefits of Plastic Valves for Water Management

Plastic valves offer significant advantages for effective water management in agriculture. Their material properties contribute to enhanced durability and reduced operational costs. Plastic valves are highly valued for their exceptional chemical compatibility and corrosion resistance. This makes them ideal for chemically aggressive environments. They are inert to corrosive substances and resistant to acids, bases, and organic solvents, performing well in harsh conditions. Poly valves offer strong resistance to corrosion, unlike metal valves which are prone to rust and degradation. They are impervious to chemical reactions with corrosive substances. This makes them suitable for industries handling chemicals, salty water, and other aggressive substances.

Plastic valves are highly resistant to acids and bases, salt solutions, organic solvents, and various corrosive chemicals. Chlorinated polyvinyl chloride (CPVC) is specifically developed for handling corrosive liquids up to 100 degrees Celsius. Polypropylene is known for high resistance against chemicals and provides high impacting strength. Plastic valves do not rust or corrode like metallic valves, enhancing their durability and efficiency.

These benefits translate into reduced maintenance requirements and lower operational costs.

- Longevity and Durability: High-quality plastic components last longer, reducing the need for frequent replacements and associated waste.

- Chemical Resistance: Plastic materials resist a wide range of chemicals, including fertilizers and pesticides. This ensures system functionality even with harsh agricultural chemicals.

- Energy Efficiency: Reduced water wastage and efficient water flow lead to lower energy consumption for pumping and distributing water.

- Lower Installation Costs: Plastic materials are generally cheaper and easier to install than metal alternatives. This contributes to more effective budget management.

- Durability and Longevity: Plastic components resist corrosion, chemicals, and UV radiation. This leads to a longer lifespan and lower maintenance costs, especially beneficial in damp climates where metal might degrade quickly.

A farm in the Scottish Highlands observed a nearly 30% reduction in maintenance costs over five years after switching to plastic pipes and fittings for their irrigation system. This demonstrates the resilience of these materials against harsh weather conditions. Plastic valves are significantly less expensive than brass or stainless steel options. Their lighter weight reduces shipping costs and simplifies installation. Smooth interior surfaces minimize flow resistance and prevent sediment buildup. This contributes to better performance in low-pressure systems.

Enhancing System Control and Automation with Plastic Valves

Plastic valves play a crucial role in enhancing system control and automation within modern irrigation. They integrate seamlessly with smart farming technologies. This allows for precise and efficient water distribution. Wireless valves are increasingly linked to cloud-based farm management platforms. This enables real-time monitoring and automated scheduling. Over 65% of new agricultural projects now incorporate IoT-enabled components, making wireless valves core elements of modern water management.

Key technologies facilitate this integration:

- Wi-Fi

- 4G/LTE

- LoRaWAN

- Zigbee

These wireless control technologies allow for easier installation and maintenance. They enhance usability in remote or large-scale farms. Precision agriculture integrates IoT devices and sensors for precise irrigation control based on real-time data. Smart irrigation systems utilize automated watering schedules and remote monitoring. Integration with AI and Machine Learning predicts irrigation needs based on weather patterns and soil conditions. Energy-efficient designs also reduce power consumption for cost-effectiveness.

Solenoid valves, integrated with sensors, data analytics, and automation technologies, enable real-time monitoring and control of irrigation. These systems optimize water usage by delivering precise amounts of water based on crop needs, soil conditions, and environmental factors. The evolution of these valves includes wireless communication for remote management and the use of IoT for precise water distribution based on real-time data. This leads to increased crop yields and improved resource efficiency. Remote monitoring and diagnostic capabilities are crucial for prompt issue identification. They minimize downtime and reduce manual inspections. Advancements in sensor-based irrigation technologies and the integration of automation and remote monitoring capabilities are essential for enhancing precision irrigation.

Synergy in Action: PP Compression Fitting for Irrigation and Plastic Valves

Building Robust and Adaptable Irrigation Networks

PP compression fittings and plastic valves form a powerful combination for irrigation. They allow farmers to construct robust and highly adaptable irrigation networks. These components simplify installation. Farmers often do not need specialized tools or extensive training. This ease of assembly means quick deployment of new systems. It also allows for easy modifications to existing layouts. The secure connections from PP compression fittings ensure system integrity. Plastic valves provide reliable control points. This synergy enables farmers to design flexible systems. They can expand or reconfigure these systems to meet changing crop needs or field conditions. This adaptability is a key advantage for dynamic agricultural environments.

Reducing Water Loss and Improving Distribution Uniformity

The combined use of PP compression fittings and plastic valves significantly reduces water loss. PP compression fittings create strong, leak-proof seals at every connection point. This prevents valuable water from escaping the system. Plastic valves, with their precise control mechanisms, ensure uniform water distribution. They direct the exact amount of water needed to each plant. This precision minimizes overwatering or underwatering. It leads to healthier crops and higher yields. By preventing leaks and ensuring even distribution, these components maximize water efficiency. This directly translates to lower operational costs for farmers. It also supports environmental sustainability by conserving a vital resource.

Real-World Examples of Optimized Irrigation

Many agricultural operations demonstrate the effectiveness of this synergy. For instance, a large-scale fruit orchard in Spain upgraded its irrigation infrastructure. They integrated PP Compression Fitting for irrigation with automated plastic valves. This allowed managers to precisely control water delivery to thousands of trees. The system reduced water consumption by 30% during dry seasons. It also improved fruit size and quality. Similarly, a greenhouse operation in the Netherlands uses these components for its hydroponic systems. The plastic valves regulate nutrient-rich water flow to individual plant trays. This ensures optimal growth conditions and minimizes waste. These real-world applications highlight the tangible benefits of optimized irrigation. They show how these technologies contribute to more efficient and sustainable food production.

Why DONSEN for Your Irrigation Needs?

Over Two Decades of Expertise in Plastic Pipeline Systems

DONSEN brings extensive experience to the plastic pipeline industry. The company established itself in 1996. It operates from Ningbo, a developed international port city. DONSEN has over two decades of experience in this field. This makes DONSEN one of the most professional manufacturers. The company specializes in producing plastic pipelines for water supply and irrigation systems. This long history demonstrates DONSEN’s deep understanding of industry needs and product quality.

Comprehensive Product Range for Water Supply and Irrigation

DONSEN offers a wide array of products for various applications. Its main products include PP-R pipes and fittings, PP compression fittings, C-PVC pipes and fittings, U-PVC pipes and fittings, and PE pipes and fittings. DONSEN also manufactures PE-RT floor heating pipes, plastic molds, and all types of plastic valves. This includes PVC, PPR, C-PVC, and brass valves. DONSEN stands as one of China’s manufacturers with the most complete product system in plastic pipes. The company uses imported high-quality raw materials. It also employs international advanced production lines. These include fiberglass production lines and PPR brass and plastic production lines. DONSEN’s products serve civil water supply, building drainage, home decoration, garden irrigation, and agricultural irrigation.

Global Certifications and Quality Assurance

DONSEN commits to high standards of quality. The company has secured numerous global certifications. These include CE certification from the European Union, NSF certification in the USA, SABS certification in South Africa, and GOST certification in Russia. DONSEN also holds WRAS certification in England, SIAA certification in Japan, and Germany’s SKZ certification. These certifications confirm DONSEN’s adherence to international quality and safety standards. DONSEN products reach over 100 countries worldwide. These markets include Russia, Ukraine, France, Italy, Mexico, the Middle East, Europe, South America, and Asia. DONSEN maintains a network of brand agents across the globe.

Future Outlook: Innovations and Sustainable Irrigation in 2026

Advancements in Material Science and Design

Material science and design continue to advance, making irrigation components more efficient and user-friendly. These innovations focus on enhancing durability, simplifying installation, and improving overall system reliability.

- The double union design of HDPE PE PP ball valves facilitates easy maintenance and replacement without interrupting the flow of materials.

- These valves are designed for easy installation, offering a hassle-free option for various applications.

- High-quality materials and construction methods ensure durability and reliability, enabling the valve to withstand challenging environments.

- A leak-proof design and smooth operation minimize downtime and ensure consistent performance.

- Enhanced jointing techniques, such as fusion welding with improved temperature control and faster heating times, minimize human error during installation, leading to more reliable and leak-free systems.

- The development of socket fusion and electrofusion methods increases the versatility of PPR fittings for seamless connections.

- Superior design features, including lighter and more compact fittings, simplify transportation and installation, making them more user-friendly.

Integration with Smart Farming Technologies

The future of irrigation heavily relies on integrating PP compression fittings and plastic valves with smart farming technologies. This integration allows for unprecedented control and optimization of water resources.

- There is a growing demand for agricultural connectors compatible with IoT-enabled systems.

- These systems feature flow sensors and automated controls for smart irrigation integration.

- PP compression accessory systems are evolving towards intelligence through IoT technology.

- Integration of intelligent sensors and remote control allows users to monitor and adjust irrigation system operations.

- Automatic adjustment of irrigation time and water volume based on soil moisture and weather forecasts enables refined water resource management.

- Precision irrigation relies on intelligent, automated, and data-driven decision support systems.

- IoT technology enables interconnectivity between devices for real-time monitoring and management of irrigation processes.

- Sensors, controllers, and irrigation equipment connect to IoT platforms for remote monitoring and automated control.

- Artificial intelligence and machine learning optimize irrigation strategies by deep learning from data, predicting water demand, and adjusting plans.

- Cloud computing and big data analytics provide powerful data processing capabilities, identifying potential irrigation problems and offering solutions.

- Data sharing and collaboration across regions are facilitated by cloud computing, enhancing overall irrigation management.

The Path to Sustainable Agricultural Practices

Advanced irrigation components like PP compression fittings and plastic valves are crucial for achieving sustainable agricultural practices. Plastic valves, specifically electric solenoid valves, are crucial for automating irrigation systems. They replace manual valves and are controlled by electrical signals, allowing integration with multi-zone irrigation controllers or timers. This enables precise, automated differential watering schedules, freeing growers from manual operation and ensuring optimal water use and labor savings. While the initial investment is higher, the gains in precision and efficiency offer a rapid return, especially for high-value crops. Polypropylene (PP) fittings are a cost-effective choice, particularly in regions where upfront investment is a primary concern. They are often used for single-season or short-term applications due to their affordability. Their use in the ‘head assembly’ of irrigation systems, where connections must be watertight, indicates their role in maintaining system integrity. High-quality PP fittings can also be reused for multiple seasons if handled carefully, contributing to cost-efficiency in irrigation setups.

The Irrigation Pp Compression Valve addresses the challenges of water management and irrigation in agriculture. With its advanced design and cutting-edge features, this valve has quickly become an essential component in modern farming practices. This valve controls the flow of water in irrigation systems, allowing farmers to optimize water usage and ensure that their crops receive the right amount of moisture for healthy growth and development. The impact of the Irrigation Pp Compression Valve on agricultural practices has been significant, with farmers reporting improvements in crop yields, water conservation, and overall sustainability. By integrating this innovative tool into their irrigation systems, farmers minimize water wastage while ensuring their crops receive the precise amount of water they need for optimal growth. The widespread adoption of the Irrigation Pp Compression Valve also contributes to environmental conservation efforts in agriculture. By reducing water usage and minimizing wastage, farmers improve their operational efficiency and play a vital role in sustainable water stewardship.

PP compression fittings and plastic valves are indispensable tools for modern agriculture. They offer unparalleled efficiency, durability, and control. These qualities are crucial for sustainable food production in 2026 and beyond. Their integration addresses global water challenges. They ensure a resilient agricultural future. A reliable PP Compression Fitting for irrigation provides robust connections. Plastic valves manage water flow precisely. This combination optimizes water use and supports environmental sustainability.

FAQ

What are the main benefits of PP compression fittings in irrigation?

PP compression fittings offer durable, leak-proof connections. They are easy to install without special tools. These fittings resist chemicals and corrosion, ensuring long-term reliability. They also contribute to significant water savings in agricultural systems.

How do plastic valves improve water management in agriculture?

Plastic valves provide precise control over water flow. They resist corrosion and chemicals, ensuring durability. These valves integrate with smart farming technologies for automated irrigation. This leads to optimized water use and reduced operational costs.

What advantages do PP compression fittings and plastic valves offer together?

Together, these components build robust and adaptable irrigation networks. They significantly reduce water loss through secure connections and precise flow control. This combination improves water distribution uniformity, enhancing crop yields and sustainability.

Why should farmers choose DONSEN for irrigation products?

DONSEN has over two decades of experience in plastic pipeline systems. They offer a comprehensive range of products for water supply and irrigation. DONSEN also holds numerous global certifications, ensuring high quality and reliability.