PN16 HDPE pipe fittings

- PN16 HDPE pipe fittings connect and secure pipes in high-pressure systems.

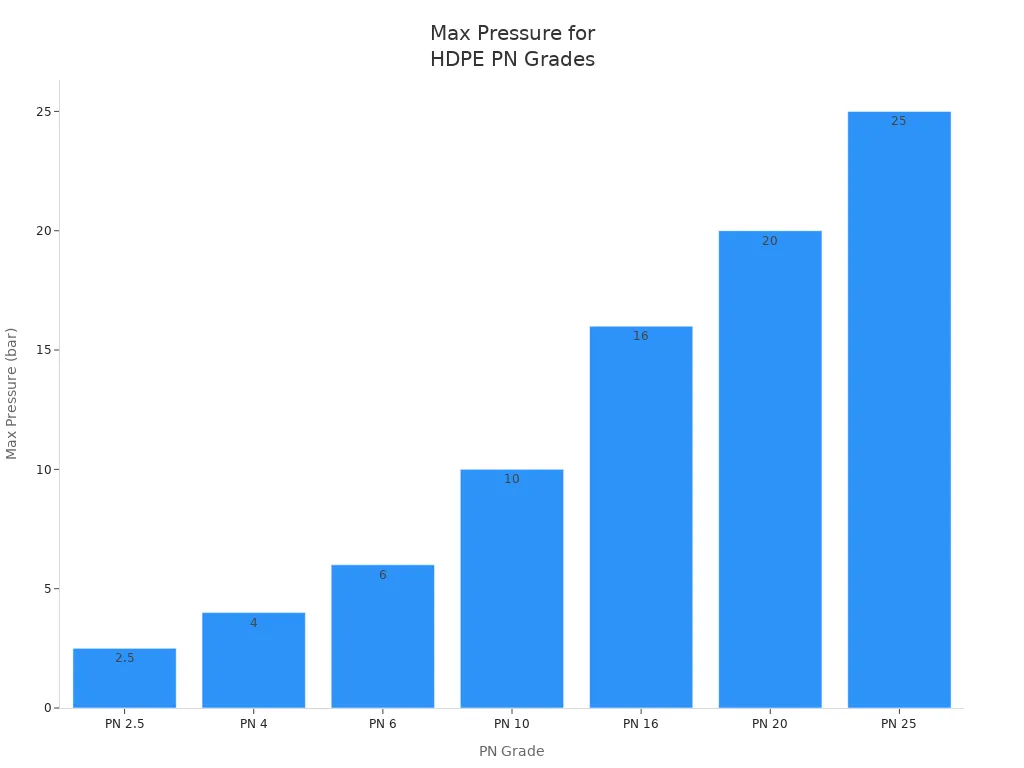

- The PN16 rating means these hdpe pipe fittings withstand up to 16 bar of pressure.

- HDPE fittings offer durability, corrosion resistance, and reliability for demanding environments.

Key Takeaways

- PN16 HDPE pipe fittings handle high pressure up to 16 bar, making them strong and reliable for demanding water and industrial systems.

- These fittings resist corrosion, chemicals, and ground movement, offering long service life and low maintenance costs.

- Installation is easy with fusion welding methods, saving time and labor while ensuring leak-free, durable joints.

HDPE fittings: Advantages and Technical Specifications

Key Benefits of PN16 HDPE Pipe Fittings

PN16 HDPE pipe fittings deliver a range of advantages over traditional metal and PVC alternatives. These benefits make them a preferred choice for high-pressure piping systems in various industries.

- Lower raw material costs due to the stable pricing of polyethylene

- Lightweight construction reduces transportation and labor expenses

- Simple installation methods, such as fusion welding, require fewer workers

- Service life often exceeds 50 years, minimizing replacement frequency

- Complete resistance to corrosion and immunity to galvanic or electrolytic attack

- Smooth interior surfaces maintain flow efficiency and reduce energy costs

- Fusion welded joints prevent leaks, reducing water loss and maintenance

- Flexibility allows the system to absorb ground movement and seismic activity

- Environmentally friendly materials lower compliance and disposal costs

HDPE fittings resist a wide range of chemicals, including acids, alkalis, and solvents. Their flexibility and fatigue resistance allow them to bend and absorb ground shifts, which is especially valuable in areas prone to soil movement or seismic activity.

Pressure Rating and Material Properties

PN16 HDPE pipe fittings are engineered to withstand a maximum working pressure of 16 bar at 20°C, including allowances for pressure surges. This rating ensures reliable performance in demanding applications such as fire mains, long-distance water transport, and high-pressure industrial systems. The PN16 designation indicates thicker pipe walls and enhanced durability.

| Parameter | Value/Description |

|---|---|

| Maximum Working Pressure (PN) | PN16 corresponds to 16 bar maximum allowable working pressure at 20°C, including pressure surge. |

| Applicable Standards | ISO 4427, DIN 8074/8075, PS-3580:1997 |

| Fitting Types and Pressure | Compression fittings: up to 10 bar |

| Butt fusion fittings: 8 to 16 bar | |

| Material Grade | PE100 provides highest pressure resistance |

| Temperature Reference | Pressure rating applies at standard 20°C |

HDPE used in PN16 fittings features high tensile strength and excellent chemical resistance. The material resists acids, alkalis, and solvents, making it suitable for corrosive environments. It remains durable under mechanical stress, resisting cracking and deformation. HDPE is non-toxic, odorless, and has a crystallinity of 80% to 90%. The softening point ranges from 125°C to 135°C, and the material performs well up to 100°C. However, it is not recommended for hot water applications due to potential deformation.

According to ISO 4427 standards, PE 80 and PE 100 grades are commonly used. The Minimum Required Strength (MRS) at 20°C over 50 years is 8 MPa for PE 80 and 10 MPa for PE 100. These properties ensure that HDPE fittings can withstand internal pressures up to 16 bar and resist chemical corrosion, contributing to long service life and reliability.

Standard Dimensions and Sizes

Manufacturers produce PN16 HDPE pipe fittings in a variety of standard sizes to meet diverse project requirements. The following table summarizes the typical size ranges and pressure ratings:

| Size Range (mm) | Pressure Rating (bar) | Notes |

|---|---|---|

| 20 to 63 | PN16 (16 bar) | Standard PN16 fittings for small diameters |

| 75 to 110 | PN10 (10 bar) | Larger sizes available but rated PN10 |

Fittings cover sizes from 20 mm (1/2 inch) up to 110 mm (4 inch). They conform to ISO and DIN standards and are designed for use with HDPE pipes. For PN16 pressure ratings, sizes from 20 mm to 63 mm are most common.

Wall thickness is determined by the Standard Dimension Ratio (SDR). For PN16 HDPE fittings, SDR11 or SDR13.5 are typical, with lower SDR values indicating thicker walls suitable for higher pressures.

| Diameter Range (mm) | Typical SDR Values for PN16 | Typical Pressure Rating (PN) | Notes |

|---|---|---|---|

| 20 – 32 | SDR11, SDR17 | PN6 – PN16 | Small diameter pipes use SDR11 or SDR17 for PN16 rating |

| 50 – 110 | SDR11, SDR17 | PN10 – PN25 | Medium diameter pipes use SDR11 or SDR17 for PN16 and higher ratings |

| Above 110 | SDR11, SDR13.5 | PN16 – PN32 | Large diameter pipes typically use SDR11 or SDR13.5 for PN16 and above |

For flanged fittings, PN10 and PN16 flanges have identical dimensions up to DN150 (NPS 6), allowing interchangeability. Above this size, PN16 flanges feature thicker walls and larger bolt holes to handle higher pressures.

HDPE fittings: Applications and Connection Methods

Common Uses in Water Supply and Industry

PN16 HDPE fittings play a vital role in municipal and industrial systems that demand high pressure and durability. Typical applications include:

- Fire mains and firefighting systems

- Potable water distribution networks

- Long-distance water transportation

- High-pressure industrial water supply

These fittings provide robust performance in environments where strength and longevity are essential. In industrial and mining operations, PN16 HDPE fittings transport slurry, chemicals, and other fluids. Their chemical resistance and ability to handle abrasive materials make them suitable for petrochemical plants, mining, and chemical processing facilities.

Types of PN16 HDPE Pipe Fittings

Manufacturers offer a wide range of PN16 HDPE fittings to accommodate various piping configurations. Common types include:

- Elbows, tees, and reducers for directional changes and branching

- Electrofusion couplers and mechanical connection fittings

- End caps, bends, branches, and sanitary fittings

Elbow, tee, and reducer fittings connect pipes of different sizes and specifications. These components use PE80 or PE100 materials and comply with standards such as ISO 4427. Electrofusion fittings often feature barcodes and welding indicators for quality control.

Connection Technologies and Installation Requirements

Installers use several connection methods for PN16 HDPE fittings. The most common are butt fusion and electrofusion. Butt fusion joins pipe and fitting ends using heat and pressure, creating strong, leak-proof joints. Electrofusion uses built-in heating elements to melt and fuse the pipe and fitting internally, ideal for confined spaces.

| Connection Technology | Description | Size Range (mm) | Pressure Rating (PN) |

|---|---|---|---|

| Butt Fusion | Heat and pressure join pipe and fittings for a homogeneous joint. | 63 – 1200 | PN16 |

| Electrofusion | Electric coils melt and join pipe and fitting internally. | 20 – 630 | PN16 |

Proper installation requires clean pipe ends, correct alignment, and adherence to manufacturer guidelines. Installers must consider temperature effects, internal pressure, and chemical exposure. Mechanical joints may require additional restraint methods to ensure leak-free performance.

Quality Control and Best Practices

Manufacturers follow strict quality control standards, including DIN 16963 and ISO 3458, to ensure dimensional accuracy and leak resistance. They conduct tests for tensile strength, hydrostatic pressure, oxidation resistance, and impact resistance. Certifications such as NSF/ANSI 61, WRAS, and DVGW confirm compliance with international safety standards.

Tip: Clean pipe ends thoroughly before fusion, use proper alignment tools, and inspect joints visually after welding. Regular inspections and pressure testing help maintain system integrity.

Best practices include using uniform trench bedding, proper backfill materials, and UV protection for outdoor installations. Installers should avoid mechanical damage during handling and follow recommended maintenance schedules to ensure long-term reliability.

PN16 pipe fittings deliver outstanding durability, flexibility, and corrosion resistance.

- They offer cost-effectiveness, long service life, and environmental benefits.

- Professionals and general users benefit from easy installation, compatibility with various systems, and reduced maintenance.

Selecting PN16 fittings ensures reliable, efficient, and safe piping solutions for demanding applications.

FAQ

What does “PN16″ mean in HDPE pipe fittings?

“PN16″ indicates the fitting can handle a maximum working pressure of 16 bar at 20°C. This rating ensures suitability for high-pressure water and industrial systems.

Can PN16 HDPE fittings be used for drinking water?

Manufacturers design PN16 HDPE fittings with non-toxic, food-grade materials. These fittings meet international standards for potable water applications.

How should installers store PN16 HDPE fittings before use?

Store fittings in a cool, shaded area. Avoid direct sunlight and mechanical damage. Proper storage maintains material integrity and extends service life.