Navigating China’s Pipe Fitting Market A 2026 Importer’s Checklist

Importers must reliably select a Chinese Pipe Fitting Supplier by 2026. Key factors ensure product quality, regulatory compliance, and efficient supply chain management. A strategic approach to Pipe Fitting Supplier selection is crucial for importers. This includes verifying manufacturing capabilities for items like an Industrial PVC flange, and ensuring expertise in Custom plastic pipe fittings. Importers need a dependable Pipe Fitting Supplier in China to meet market demands effectively.

Key Takeaways

- Always check a supplier’s business papers and licenses to make sure they are real and follow the law.

- Look for suppliers who have important quality certificates like ISO 9001 and CE Marking to ensure good products.

- Make sure the supplier has good ways to check product quality, like testing materials and checking sizes.

- Choose payment methods that are safe, like Letters of Credit for big orders, to protect your money.

- Understand how products will be packaged and shipped to avoid damage and delays.

Understanding the Chinese Pipe Fitting Supplier Landscape

Current Market Dynamics for Pipe Fitting Suppliers

The Chinese pipe fitting market experiences dynamic shifts. Industrialization and significant infrastructure investments drive its growth. This market features many local manufacturers, leading to intense competition. Manufacturers increasingly focus on product quality and adherence to international standards. There is also a growing demand for corrosion-resistant fittings. Importers must understand these trends to select a suitable Pipe Fitting Supplier.

Key Manufacturing Hubs and Specializations of Pipe Fitting Suppliers

China’s pipe fitting production concentrates in several key manufacturing hubs. These include Anyang in Henan, Wenzhou in Zhejiang, Guangzhou, Hebei province, and Tianjin. Each region often develops specific specializations. For example, Liaoning Hongye Pipe Fittings Co., Ltd. in Liaoning offers diverse material selection, including carbon steel, alloy steel, and non-ferrous metals. They also provide flexible production capacity for both small and large batches. Sichuan Changcheng Special Steel Co., Ltd. in Sichuan specializes in high-alloy steel and heat-resistant steel pipe fittings. These are for high-end applications like aerospace, power generation, and petrochemicals. Their expertise lies in high-end manufacturing technology and R&D-driven product development.

Types of Pipe Fitting Suppliers and Their Offerings

Importers encounter various types of Pipe Fitting Suppliers in China. Large-scale manufacturers often offer a wide range of products and high production volumes. They typically have advanced facilities and comprehensive quality control systems. Specialized manufacturers focus on niche products, such as specific materials or complex designs. These suppliers often possess unique expertise and advanced customization capabilities. Trading companies also play a role. They source products from multiple factories, offering a broader selection and potentially more flexible order quantities. Importers should evaluate their specific needs to determine the most suitable type of supplier.

Essential Vetting for a Reliable Pipe Fitting Supplier

Verifying Business Registration and Licenses of a Pipe Fitting Supplier

Importers must confirm a potential Pipe Fitting Supplier possesses valid business registration and operational licenses. This step establishes legitimacy and legal compliance. Requesting copies of their business license, export license, and any relevant industry-specific permits is crucial. Additionally, importers should ask for specific Certificates of Origin, which vary based on the destination country. These documents ensure proper customs clearance and potential preferential duty treatment.

| Document Type | Description / Applicable Regions |

|---|---|

| Form A | General Certificate of Origin rules. |

| Form E | For exports to ASEAN countries (Brunei, Cambodia, Indonesia, Laos, Malaysia, Myanmar, Philippines, Singapore, Thailand, Vietnam). |

| Form F | China-Chile Free Trade Area preferential Certificate of Origin, allowing preferential duty treatment for Chilean importers. |

| Form M | For South Korea, India, Sri Lanka, and Bangladesh. |

| Form P | For Pakistan. |

Assessing Financial Stability and Operational History of a Pipe Fitting Supplier

Evaluating a supplier’s financial stability prevents future supply chain disruptions. Importers should request financial statements and analyze key indicators. These include:

- Total Revenue

- Net Profit Margin

- Current Ratio

- Debt-to-Equity Ratio

- Operating Cash Flow

- Credit Ratings

Beyond traditional metrics, online revenue and reorder rates offer insights into a supplier’s market demand and client retention. A long operational history often indicates reliability and experience in the industry.

Evaluating Communication and Responsiveness of a Pipe Fitting Supplier

Effective communication is vital for successful international trade. Importers should assess a supplier’s responsiveness during initial inquiries. Reliable suppliers often provide fast, efficient responses. For example, some companies ensure 24-hour responses to inquiries. Others, like Henan Jiashang Plastic Industry Co., Ltd., respond in under 1 hour, especially when existing mold tooling allows for quicker sample prioritization. Pengrun, another pipe fitting manufacturer, states they provide instant replies to customer inquiries. Clear, timely communication minimizes misunderstandings and ensures smooth project execution.

Quality Assurance and Compliance Standards for Pipe Fitting Suppliers

International Certifications and Standards (ISO, API, ASTM) for Pipe Fitting Suppliers

A reliable Pipe Fitting Supplier demonstrates commitment to quality through international certifications. These certifications ensure products meet global standards. CE Marking indicates compliance with European Union safety and environmental rules. This is essential for accessing the EU market. UL Certification confirms safety and performance testing, especially for electrical and industrial uses. ISO 9001 certification shows a robust quality management system. API Certification is vital for pipe fittings in the oil and gas industry, meeting rigorous demands. NSF Certifications apply to potable water systems, ensuring material safety. DVGW Certifications are important in Germany for gas and water supply. WRAS Approvals verify compliance for public water systems in the UK. UPC standards cover plumbing systems in the United States. ABS and DNV Certifications are crucial for marine and offshore industries.

Internal Quality Control Processes and Documentation of a Pipe Fitting Supplier

Suppliers must implement strong internal quality control processes. Material testing includes spectroscopic analysis to confirm material grades. They also document heat treatment and conduct impact testing for low-temperature applications. Material test certificates detail chemical analysis and mechanical properties. Dimensional inspection uses coordinate measuring machines for accurate measurements. Pressure testing, often hydrostatic, verifies the product’s ability to withstand working pressures. Non-destructive testing (NDT) methods like X-rays find internal flaws. Manufacturing process documentation ensures consistent quality. This includes process control records for critical parameters like welding and heat treatment. Traceability systems track materials from raw form to finished products. Visual inspections check for defects like cracks or uneven surfaces. Mechanical inspections use tools to check alignment and strength. Auditing quality control procedures ensures adherence to standards.

Material Traceability and Testing Protocols from a Pipe Fitting Supplier

Material traceability provides transparency and assurance. Dimensional Inspection Reports confirm components meet specified geometric requirements. These reports include measurements for outside diameter, wall thickness, and end preparations. Traceability Records track mechanical components from raw material sourcing to final delivery. This documentation includes material source identification, production lot numbers, and manufacturing dates. For critical applications, it details the entire supply chain. Advanced systems use digital documentation and QR codes for instant access. Mill Test Reports (MTRs) are issued for every product bundle. They include complete heat traceability, chemical analysis, and tensile properties. A unique tag data system with each product bundle enables further traceability. ID stamping on products, especially for U.S. projects, ensures traceability even after coating wear.

Production Capabilities of a Pipe Fitting Supplier

Manufacturing Capacity and Scalability of a Pipe Fitting Supplier

A reliable Pipe Fitting Supplier demonstrates robust manufacturing capacity. They handle diverse order volumes, from small batches to large-scale industrial projects. Their operations ensure consistent quality across all production levels. Scalability allows them to adjust production quickly, meeting fluctuating market demands. This flexibility prevents delays and maintains a steady supply chain for importers.

Advanced Production Equipment and Techniques of a Pipe Fitting Supplier

Leading manufacturers utilize advanced production equipment and techniques. Victaulic, for example, employs grooved pipe joining technology for easy installation and flexible connections. They also invest in advanced sealing technologies for leak-free performance. KSB SE & Co. KGaA uses high-grade stainless steel and special alloys. They integrate smart technology like sensors for remote monitoring. Crane Co. applies precision machining for accuracy and quality. They also use advanced corrosion-resistant coatings to extend product life. Parker Hannifin focuses on high-pressure and high-temperature applications with precision engineering. Swagelok features a unique two-ferrule tube-fitting design for leak-tight connections. Georg Fischer Piping Systems uses innovative heat-fusion joining technologies. Mueller Industries operates facilities with state-of-the-art machinery for efficient production. Watts Water Technologies develops innovative designs, including self-sealing and smart fittings. Kitz Corporation uses advanced manufacturing and strict quality control for fittings from high-grade materials.

Customization and Fabrication Expertise of a Pipe Fitting Supplier

Suppliers offer extensive customization and fabrication expertise. They provide expert consulting and engineering services. This helps design custom solutions and assists with mission-critical designs. They also offer wear-resistant designs for custom pipe bends. These bends are built to last using state-of-the-art equipment. Customization options include:

- Hardened bends with pipe and tube diameters from 2.5” (63.5mm) NPS to 26” (660.4mm) OD.

- Any angle up to 180°.

- A complete range of materials: carbon steel, alloys, stainless steel, and structural shapes.

Suppliers also perform various finishing services. These include cut grooving for carbon steel pipe down to ¾”. They offer roll grooving for carbon steel, stainless steel, and copper pipes. Threading services are available for carbon steel and stainless steel. Pipe cutting, both square and bevel, is also a common offering. They handle custom laterals, butt weld crosses, true wyes, and flanged fittings. Design and fabrication involve understanding unique requirements and using advanced techniques. Inspection and testing processes, like UT testing and radiographic inspections, verify specifications. They also provide material reports and certifications, ensuring full traceability.

Technical Support from Your Pipe Fitting Supplier

Design and Engineering Assistance from a Pipe Fitting Supplier

A reliable pipe fitting supplier offers crucial design and engineering assistance. They provide design solutions tailored to specific project needs. Suppliers also offer engineering services for all their products. For example, Tri Star Industrial offers custom-designed fabricated pipe supports and custom fabricated metal services. They work closely with customers to meet specific project specifications. This support often includes pipe hanger design and engineering. Suppliers also provide drafting services, including 3D CAD models. They conduct system analysis and product qualification testing. Some suppliers supervise client design personnel. They also design, test, and rebuild constant supports, hydraulic snubbers, and variable springs. For the nuclear industry, ASC Engineered Solutions provides dependable and innovative pipe support solutions. Their ASME NS and NPT certifications demonstrate specialized engineering capabilities.

Post-Sales Technical Support from a Pipe Fitting Supplier

Comprehensive technical support is highly valued by professionals. Suppliers emphasize reliable post-sales assistance as crucial for customer satisfaction. They often provide detailed technical documentation to enhance confidence in project outcomes. On-demand consultation is also offered to further support professionals in their projects. Suppliers commonly provide ongoing technical support as part of their after-sales services. This addresses any questions or issues that may arise post-purchase. Professional technical support includes round-the-clock assistance from experts. They offer tailored advice and solutions from initial consultation through implementation. Comprehensive after-sales service goes beyond simple follow-ups. This service encompasses maintenance, troubleshooting, and upgrades. It ensures product performance throughout its lifecycle.

Problem-Solving and Innovation Capabilities of a Pipe Fitting Supplier

A strong pipe fitting supplier demonstrates excellent problem-solving and innovation capabilities. They proactively address challenges and offer creative solutions. This includes adapting existing products or developing new ones for unique applications. Suppliers with a focus on innovation stay ahead of industry trends. They incorporate new technologies and materials into their offerings. This commitment to problem-solving and innovation ensures long-term partnerships. It also helps importers navigate complex project requirements effectively.

Material Standards and Product Specifications from a Pipe Fitting Supplier

Adherence to Industry-Specific Material Grades by a Pipe Fitting Supplier

Importers must ensure a pipe fitting supplier adheres to specific material grades. This guarantees product performance and suitability for intended applications. Different industries require distinct material properties.

- Stainless Steel Pipe Fittings:

- Common Grades: SS 304/316 (plumbing, food processing, chemical industries, water systems), SS 321 (high-temperature applications), SS 310 (extreme temperatures in power plants, aerospace).

- Duplex Stainless Steel Pipe Fittings:

- Common Grade: Duplex 2205 (high pressure, aggressive environments like offshore platforms, desalination plants, chemical processing).

- Super Duplex Stainless Steel Pipe Fittings:

- Common Grade: Super Duplex 2750 (chemical processing, seawater desalination, offshore oil and gas industries).

- Inconel/Incoloy Pipe Fittings:

- Common Grades: Inconel 625 (aerospace, chemical processing, power generation), Incoloy 825 (corrosive chemicals like sulfuric and phosphoric acid environments).

- Monel Pipe Fittings:

- Common Grade: Monel 400 (marine, chemical, and power generation industries).

- Titanium Pipe Fittings:

- Common Grades: Titanium Grade 2 (general-purpose in marine, chemical, HVAC systems), Titanium Grade 5 (Ti-6Al-4V) (aerospace, medical implants).

Suppliers must provide documentation confirming material composition and grade. This ensures compliance with project specifications.

Precision in Product Dimensions and Tolerances from a Pipe Fitting Supplier

Precision in product dimensions and tolerances is critical for proper fit and function. Pipe fittings must meet exact measurements to ensure leak-free connections. Importers should verify a supplier’s capability to maintain strict dimensional control.

| Standard | Thread Type | Tolerance Class (Example) |

|---|---|---|

| ASME B1.20.1 | NPT (tapered) | L1/L2 gaging required |

| ISO 7-1 | BSPT (tapered) | GO/NO-GO thread plug/ring gage per ISO 7-2 |

| ISO 228-1 | BSPP (parallel) | Major/minor/pitch dia per standard |

| ISO 965-1/-2 | Metric | 6H (internal) / 6g (external) |

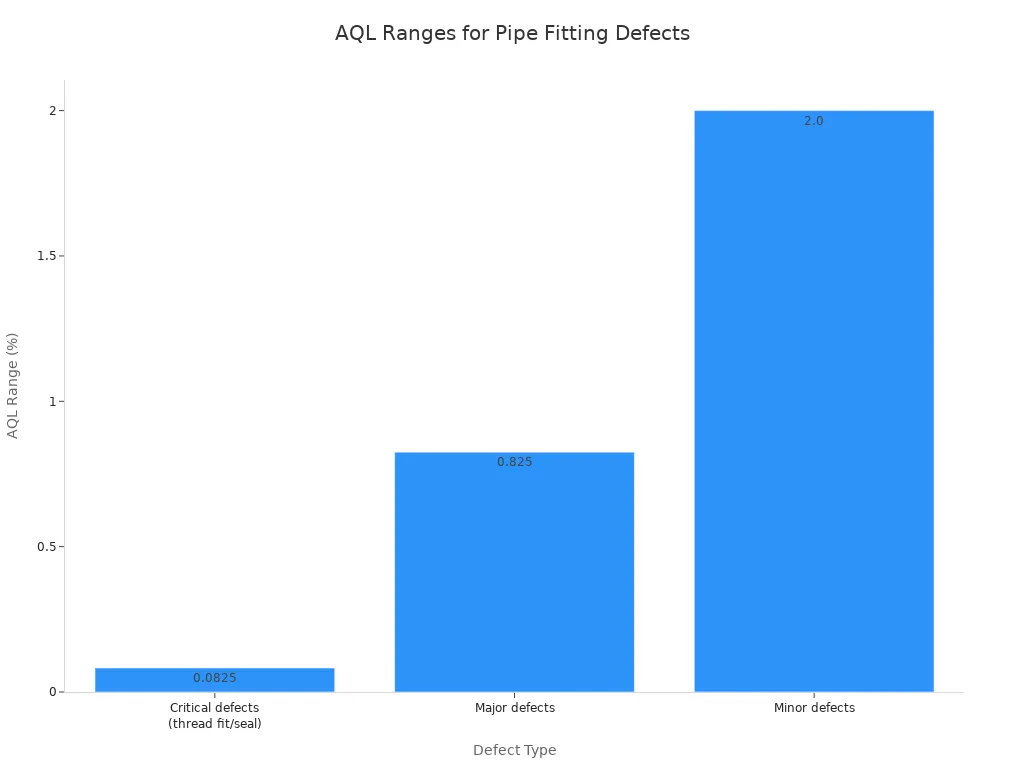

For critical dimensions, such as pitch diameter or sealing face height, suppliers set a Cpk (Process Capability Index) of ≥1.33 for steady production. For new parts or processes, they aim for Cpk ≥1.67 during the first three lots. If sustaining production Cpk falls below 1.33, suppliers implement 100% gauging or tighten sampling. Suppliers also use Acceptable Quality Limit (AQL) ranges for defect types.

| Defect Type | AQL Range |

|---|---|

| Critical defects (thread fit/seal) | 0.065–0.10 |

| Major defects | 0.65–1.0 |

| Minor defects | 1.5–2.5 |

Surface Treatment and Coating Options from a Pipe Fitting Supplier

Surface treatments and coatings enhance the durability and performance of pipe fittings. They provide crucial protection against corrosion and wear. Importers should consider the environmental conditions where the fittings will operate.

- Polyurethane Coatings: Offer a high-gloss finish, good chemical resistance, and protection against moisture, sunlight, and various chemicals. They are suitable for both indoor and outdoor use and maintain integrity and appearance over time.

- Epoxy Coatings: Known for excellent adhesion to brass, forming a durable barrier against corrosive substances like acids, alkalis, and salts. They also provide good abrasion resistance, making them suitable for industrial applications.

- Zinc-based Coatings (e.g., galvanized coatings): Provide sacrificial protection where the zinc corrodes preferentially, safeguarding the underlying brass. This is particularly effective in outdoor or high-salt environments.

- Passivation: A chemical treatment using solutions like nitric or chromic acid to create a thin, stable oxide layer on brass, enhancing natural corrosion resistance and preventing tarnish, discoloration, and pitting corrosion.

- Polishing: A mechanical treatment that smooths the surface, reducing areas where moisture and corrosive substances can accumulate. While it improves appearance and offers some anti-corrosion benefits, it is often combined with other treatments for comprehensive protection.

These treatments extend the lifespan of fittings and reduce maintenance costs.

Pricing Models and Cost Efficiency with a Pipe Fitting Supplier

Transparent Pricing Structures from a Pipe Fitting Supplier

Importers seek clear and straightforward pricing from their pipe fitting suppliers. A transparent pricing structure helps buyers understand all costs involved. Suppliers should provide detailed breakdowns of unit prices, minimum order quantities, and any potential volume discounts. They also clearly outline charges for tooling, customization, or special packaging. Hidden fees can disrupt budgets and damage trust. Therefore, a reliable supplier offers comprehensive quotes upfront, ensuring financial predictability for importers.

Value-Added Services vs. Base Price from a Pipe Fitting Supplier

Evaluating a supplier involves more than just comparing base prices. Value-added services significantly impact overall cost-efficiency. These services can transform raw material costs into ready-to-use components, saving time and money. Consider how these services contribute to your bottom line:

- Reduced Waste: Precise cutting services minimize scrap and excess inventory. This leads to cost savings by ensuring buyers only purchase necessary materials.

- Convenience: A single supply partner offering services like cutting, threading, or coating simplifies procurement. It avoids the expense of acquiring and maintaining specialized equipment.

- Customization: Services such as fixed lengths, machined ends, or special coatings eliminate extra processing. This saves time and cost by providing materials ready for immediate use.

- Improved Performance: Protective coatings and prefabrication enhance product longevity. This avoids third-party involvement and offers a more cost-effective solution.

- Quality Assurance: Testing and inspection services ensure products meet quality standards. This reduces the risk of costly failures and downtime by providing reliable materials.

Long-Term Cost-Benefit Analysis with a Pipe Fitting Supplier

Importers conduct a thorough long-term cost-benefit analysis. This evaluation extends beyond the initial purchase price. It includes factors like product durability, warranty terms, and the supplier’s after-sales support. A higher-priced fitting with superior quality and a longer lifespan often proves more economical over time. It reduces replacement costs and minimizes operational downtime. Reliable suppliers offer consistent quality, which prevents costly project delays and rework. Therefore, a strategic importer considers the total cost of ownership, not just the upfront expense.

Logistics and Supply Chain Management with a Pipe Fitting Supplier

Packaging and Handling Standards from a Pipe Fitting Supplier

Proper packaging and handling standards are crucial for pipe fitting shipments. Importers ensure packaging meets project-specific requirements and international shipping standards. This prevents damage during transit. Suppliers provide beveled end protection for each fitting using durable plastic protector caps. They package each fitting size separately and label it with essential information. This includes the purchase order number, item code, material specification, size, schedule/thickness, and pressure rating. For small orders, suppliers consolidate separate, size-wise packaging into a larger, clearly marked container. This makes identification easy. They design packaging and internal dunnage to protect contents in external, non-covered storage for at least 12 months. Suppliers also optimize container size to eliminate excessive free space, reducing shipping costs and preventing material damage. They use proper stuffing. All wooden packaging must be heat-treated, fumigated, and ISPM 15 certified, with certification shared.

Shipping Options and Lead Times from a Pipe Fitting Supplier

Importers consider various shipping options and their associated lead times when sourcing pipe fittings from China. These choices impact delivery schedules and overall project timelines.

| Shipping Option | Origin | Destination | Lead Time |

|---|---|---|---|

| Sea Freight | China | Bahrain | 20-30 days |

| Fast Sea Freight | China | Bahrain | 15-20 days |

| Air Freight | China | Bahrain | 3-7 days |

| Air Freight | Guangzhou, China | Seattle, USA | 2-3 days |

Air freight offers the fastest delivery, suitable for urgent orders, but at a higher cost. Sea freight provides a more economical option for larger volumes, though with longer lead times. Importers select the best option based on their budget and urgency.

Supply Chain Visibility and Tracking from a Pipe Fitting Supplier

Effective supply chain visibility and tracking give importers control over their shipments. Technologies like RFID tags utilize electromagnetic fields for automatic identification and tracking. They enable non-line-of-sight scanning, rapid batch scanning, and reduce human error. QR and barcodes offer cost-effective alternatives. They provide significant improvements over manual tracking. QR codes store more data and are scannable with mobile devices. Real-time software platforms transform how companies monitor pipe spools from fabrication through installation. These platforms provide a competitive advantage and become an industry necessity for large-scale operations. Unified freight tracking solutions offer an all-in-one approach to supply chain visibility. They deliver efficiency, clarity, and control. These solutions standardize data formats, making performance analysis easier. They also help compare suppliers and carriers, and share real-time data with all stakeholders.

Payment Terms and Dispute Resolution with a Pipe Fitting Supplier

Secure Payment Methods and Terms with a Pipe Fitting Supplier

Importers must establish secure payment methods and clear terms with their pipe fitting suppliers. This protects financial interests and ensures smooth transactions. For large transactions, a Letter of Credit (L/C) offers the most reliable and professional payment method. The importer’s bank issues the L/C, guaranteeing payment to the supplier upon order completion or fulfillment of specified conditions. L/Cs ensure timely payment, and the buyer does not pay in advance. An expiry date pressures the supplier for timely dispatch. However, it involves extensive paperwork and documentation due to bank involvement.

Bank Transfers (T/T) are generally safe, fast, and affordable for international transactions. Suppliers widely accept them. They offer reliability, security, and currency flexibility. T/T supports large transactions with lower fees for bigger amounts. However, they are typically irrevocable, which can disadvantage buyers in case of disputes. PayPal is user-friendly and secure, offering quick transactions and dispute resolution. It suits sample orders or small transactions. Despite its ease of use, it comes with higher transaction fees. Many Chinese suppliers do not prefer it for large orders due to high withdrawal fees and restrictions in China.

Contractual Agreements and Legal Protections with a Pipe Fitting Supplier

Comprehensive contractual agreements are essential for importers. These documents clearly define the terms of engagement. A strong contract outlines product specifications, quality standards, delivery schedules, and payment terms. It also specifies intellectual property rights and confidentiality clauses. Importers should ensure the contract includes provisions for legal protections. This safeguards their interests in case of non-compliance or disputes. Legal counsel can review these agreements to ensure enforceability under international law.

Mechanisms for Conflict Resolution with a Pipe Fitting Supplier

Even with clear contracts, conflicts can arise. Importers need defined mechanisms for conflict resolution. Initial steps often involve direct negotiation between parties. If negotiation fails, mediation offers a neutral third party to facilitate a resolution. Arbitration provides a more formal process, where an impartial arbitrator makes a binding decision. The contract should specify the jurisdiction and rules for arbitration. This ensures a clear path for resolving disagreements efficiently and fairly.

Future Trends for Pipe Fitting Suppliers in 2026

Adapting to Regulatory Changes for Pipe Fitting Suppliers

The pipe fitting industry constantly evolves. Suppliers must adapt to upcoming regulatory changes. These changes often favor innovative, compliant solutions over older products. Stricter safety and environmental standards compel manufacturers to adopt higher-quality, certified fittings. This trend creates barriers for low-cost, non-compliant competitors. Importers should prioritize suppliers demonstrating a clear understanding of global and regional regulations. They must also show a commitment to continuous compliance. This ensures product acceptance in diverse markets.

Embracing Sustainable Manufacturing Practices by Pipe Fitting Suppliers

Sustainability is a growing priority for pipe fitting suppliers. Manufacturers increasingly adopt eco-friendly production methods. This includes reducing waste, conserving energy, and using recyclable materials. Some suppliers invest in renewable energy sources for their factories. Others implement closed-loop systems to minimize water usage. Importers benefit from partnering with suppliers committed to sustainability. This aligns with global environmental goals. It also enhances their own corporate social responsibility profiles.

Fostering Long-Term Partnerships with Pipe Fitting Suppliers

Building strong, long-term relationships remains crucial for importers. Suppliers value consistent business and clear communication. These partnerships lead to mutual benefits. Importers gain preferential pricing, customized solutions, and reliable supply chains. Suppliers receive stable demand and valuable feedback for product development. Trust and transparency form the foundation of these successful collaborations. Regular communication and shared goals strengthen these vital business ties.

This checklist guides importers in selecting a reliable Pipe Fitting Supplier. It covers crucial aspects like quality, compliance, and communication. A well-chosen supplier ensures project success and operational efficiency. Importers should apply this comprehensive checklist. It helps them make informed decisions for their 2026 sourcing needs.

FAQ

How do importers verify a Chinese pipe fitting supplier’s legitimacy?

Importers verify legitimacy by requesting business registration and operational licenses. They also ask for export licenses and specific Certificates of Origin. These documents confirm legal compliance and proper customs clearance. This step establishes the supplier’s credibility.

Which international certifications are most important for pipe fittings?

Key certifications include ISO 9001 for quality management and CE Marking for EU compliance. API Certification is vital for oil and gas fittings. NSF Certifications ensure safety for potable water systems. Importers should check for certifications relevant to their specific market.

How can importers ensure product quality from a Chinese pipe fitting supplier?

Importers ensure quality by reviewing the supplier’s internal quality control processes. They check for material traceability and testing protocols. This includes material test reports and dimensional inspection reports. Suppliers should provide documentation for all quality checks.

What are common secure payment terms with Chinese pipe fitting suppliers?

Common secure payment terms include Letters of Credit (L/C) for large transactions. Bank Transfers (T/T) offer a widely accepted, reliable option. PayPal suits smaller orders due to its user-friendliness. Importers choose terms based on transaction size and risk tolerance.