Maximize Your Garden’s Potential with PP Compression Fittings

PP compression fittings significantly enhance irrigation efficiency in garden irrigation piping. They provide a reliable connection between PE pipes & fittings, ensuring water flows smoothly throughout the irrigation pipe system. Choosing the right fittings is crucial for maximizing garden productivity. Properly selected fittings lead to effective water delivery, which supports healthy plant growth and reduces waste. For those seeking quality solutions, partnering with a trusted plastic compression fittings manufacturer can make a difference in achieving optimal irrigation results.

Key Takeaways

- PP compression fittings enhance irrigation efficiency by providing reliable connections, ensuring smooth water flow.

- These fittings are durable, resistant to corrosion, and suitable for various temperatures, leading to lower maintenance costs.

- Installation is easy and requires only basic tools, allowing gardeners to set up their systems quickly and cost-effectively.

- Regular maintenance, such as checking filters and flushing lines, is essential for preventing leaks and ensuring optimal performance.

- Understanding the specific water needs of plants and using PP compression fittings can significantly improve garden productivity.

Benefits of PP Compression Fittings

PP compression fittings offer numerous advantages that make them an excellent choice for garden irrigation systems. These fittings enhance the overall efficiency and reliability of irrigation setups. Here are some key benefits:

- Durability: PP compression fittings are highly durable and resistant to corrosion. Unlike metal fittings, they do not rust, ensuring a longer lifespan. They can withstand a wide range of temperatures, making them suitable for both hot and cold water applications. This durability translates into lower maintenance costs over time.

- Ease of Installation: Installing PP compression fittings is straightforward. Gardeners can use basic hand tools, which reduces the need for specialized equipment. This ease of installation minimizes labor costs and allows for quick setup.

- Reusability and Adjustability: These fittings can be disassembled and reinstalled multiple times without damage. This feature allows gardeners to adjust their irrigation systems as needed, further reducing repair costs.

- Compatibility: PP compression fittings work well with various pipe materials, including PE pipes. This compatibility eliminates the need for specific adapters, simplifying the installation process.

- Environmental Benefits: Using PP compression fittings contributes to sustainability efforts. They are recyclable, which helps reduce waste. Additionally, their production results in fewer greenhouse gas emissions compared to traditional materials. Their lightweight nature also leads to lower transportation costs and reduced fuel consumption during shipping.

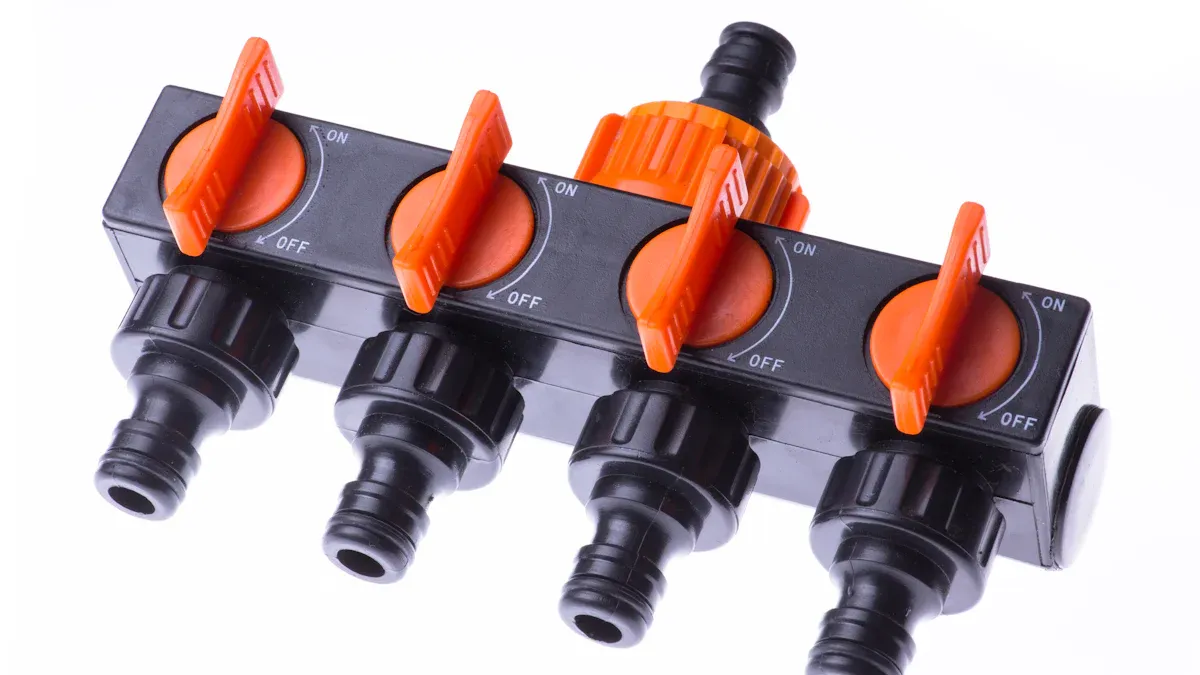

- Variety of Options: Different types of PP compression fittings serve specific functions in irrigation systems. For example, elbow and tee fittings allow for direction and angle adjustments, while control switch fittings like ball valves manage water flow. A table summarizing common types and their functions is provided below:

| Type | Function |

|---|---|

| Coupling | Connects two pipes together. |

| Elbow | Changes the direction of the pipe. |

| Tee | Allows for branching of the pipeline. |

| Reducing Coupling | Connects pipes of different diameters. |

| End Cap | Closes the end of a pipe. |

| Male/Female Adaptor | Connects to male or female fittings. |

| Saddle Clamp | Secures pipes in place. |

| Compact PP Valve | Controls flow in the system. |

Compatibility with PE Pipes

PP compression fittings exhibit excellent compatibility with PE pipes, making them a preferred choice for irrigation systems. Understanding how these fittings connect to various grades and diameters of PE pipes is essential for achieving optimal performance.

- Size Compatibility: PP compression fittings must match specific pipe outer diameters to ensure sealing performance. This compatibility is crucial for preventing leaks and maintaining efficient water flow.

- Measurement Practices: Gardeners should use calipers or pipe gauges for precise measurement of the pipe’s outer diameter. Accurate measurements help avoid issues during installation.

- Standards: Most fittings adhere to standardized manufacturing tolerances for consistent performance. These standards ensure that the fittings will work effectively with PE pipes in various applications.

- Common Issues: One common mistake involves confusing nominal size with actual measurement. Mixing inch-based and metric products can also lead to compatibility problems. Gardeners should be cautious to avoid these pitfalls.

Tip: Always verify the specifications of both the PP compression fittings and the PE pipes before installation. This practice helps ensure a secure and leak-free connection.

The certification of PP compression fittings indicates they have undergone evaluations for pressure, durability, and safety. This evaluation ensures compatibility with PE pipes in irrigation systems. Additionally, standards such as EN 12201 specify requirements for pipe fittings used in water supply and irrigation systems, including those made from PE and PP.

By ensuring compatibility between PP compression fittings and PE pipes, gardeners can create efficient irrigation systems that promote healthy plant growth and conserve water.

Installation Tips for PP Compression Fittings

Installing PP compression fittings correctly is essential for achieving leak-free connections in your garden irrigation system. Here are some valuable tips to ensure a successful installation:

- Familiarize Yourself with Components: Understand the parts of the fitting, including the body, nut, and compression ring. Knowing how these components work together will help during installation.

- Measure Accurately: Before cutting the pipe, measure it precisely. This step ensures a proper fit and prevents leaks.

- Lubricate the Pipe End: Apply a compatible lubricant to the end of the pipe. This practice eases insertion into the fitting and helps create a tight seal.

- Use the Right Tools: Employ appropriate tools, such as a wrench, to tighten the nut securely. Using the correct tools minimizes the risk of damaging the fittings.

To avoid common installation mistakes, consider the following:

- Insufficient Preparation: Always clean the piping system and inspect all pipes and fittings for defects. A clean workspace leads to better results.

- Poor Jointing: Execute the heat fusion technique properly. Weak joints can lead to leaks, so ensure a solid connection.

- Improper Alignment: Align pipes correctly to prevent bends or kinks. Misalignment can restrict water flow and cause issues.

- Inadequate Support: Use support brackets and hangers to prevent sagging. Proper support reduces stress on joints.

- Inadequate Testing: After installation, thoroughly test the system to ensure it is leak-free before operation. This step saves time and resources in the long run.

The installation time for PP compression fittings is generally quick, with some sources indicating that it can take as little as five minutes. By following these tips, gardeners can ensure their irrigation systems operate efficiently and effectively.

Maintenance for PP Compression Fittings

Proper maintenance of PP compression fittings is essential for ensuring their longevity and optimal performance in garden irrigation systems. Regular upkeep can prevent leaks and other issues that may disrupt water flow. Here are some recommended maintenance procedures:

- Check Filters Monthly: Regularly inspect and clean or replace clogged filters to maintain water quality.

- Flush Lines Seasonally: Perform this task at least three times a year using clean water to remove debris and buildup.

- Inspect Emitters Regularly: Look for clogs, leaks, or damage to ensure efficient water distribution.

- Monitor Pressure: Keep the system pressure between 20-50 psi for optimal performance. This range helps prevent stress on fittings.

- Winterize System: Before temperatures drop below 37°F, take steps to prevent freeze damage.

Cleaning methods also play a crucial role in maintaining the performance of PP compression fittings. Here are some effective techniques:

- Pre-Installation Cleaning: Wipe fittings with isopropyl alcohol and use compressed air to remove dust.

- Post-Installation Flushing: Run potable water through the system for 10-15 minutes to clear any debris.

- Long-Term Maintenance: For severe blockages, use a pipe cleaning brush to ensure unobstructed flow.

Gardeners should also be aware of signs indicating the need for replacement of fittings. These signs include:

- Leakage at connections

- Visible cracks or deformation

- Unusual noises during operation

- Changes in water pressure or flow

- Discoloration or odor in the water supply

By following these maintenance tips, gardeners can extend the lifespan of their PP compression fittings and ensure a reliable irrigation system.

Common Troubleshooting Issues with PP Compression Fittings

Gardeners may encounter several common issues with PP compression fittings in their irrigation systems. Understanding these problems can help them maintain efficient water flow and prevent leaks. Below are some frequently reported issues:

| Issue Type | Description |

|---|---|

| Improper use | Compression fittings should only be used on stationary connections to avoid leaks. |

| Incorrect assembly | Proper installation is crucial; incomplete insertion can lead to leakage. |

| High pressure | Excessive pressure can distort the o-ring, leading to leaks, especially at angled connections. |

When leaks occur, gardeners can follow these troubleshooting steps to identify and resolve the issue:

- Prepare the Area: Ensure that the area around the PP compression fitting is dry and clean.

- Visual Inspection: Look for any visible signs of water droplets, dampness, or discoloration around the fitting.

- Feel for Moisture: Gently run fingers along the joint and surrounding areas to detect any wetness.

- Use a Clean Cloth: Wipe the entire fitting to absorb any moisture and facilitate new leak detection.

- Monitor for Water Droplets: Observe the fitting for any formation of water droplets after wiping.

- Run Water Through the System (Optional): Simulate normal operating conditions and observe for leaks.

- Check Joints and Seals: Inspect the integrity of the O-ring or gasket and ensure it is properly seated.

- Use a Flashlight (if needed): Illuminate the fitting to detect small water droplets or signs of dampness.

- Repeat if Necessary: Conduct multiple inspections for thoroughness.

- Inspect Adjacent Components: Check nearby pipes and components for any signs of leakage.

Blockages can also disrupt the flow in irrigation systems. Clogging often occurs due to debris, dirt, or minerals in the water. To prevent this, gardeners should regularly inspect their systems and clean filters. Installing water filters at the head of the irrigation system can help eliminate impurities and prevent blockages.

To avoid recurring issues, gardeners should follow these best practices:

- Always use sharp, clean cutters for tubing to ensure smooth insertion and proper sealing.

- Test every connection at full operating pressure before finalizing installation to easily address any issues.

- Ensure the system operates within the specified pressure range for the fittings, typically 15-30 PSI for drip fittings.

- Verify proper tubing cut quality, insertion depth, and matching tubing diameter to fitting specifications.

- Prevent leaks by ensuring proper tubing preparation and correct fitting selection.

By addressing these common troubleshooting issues, gardeners can maintain their irrigation systems effectively and ensure optimal performance.

Using PP compression fittings and PE pipes significantly enhances garden productivity. These fittings offer durability and ease of installation, making them ideal for both home users and large-scale agricultural projects. They help manage water resources effectively, leading to increased crop yields.

To maximize garden potential, gardeners should understand the specific water needs of their plants. Deep watering less frequently, adjusting schedules based on moisture levels, and using mulch can improve irrigation efficiency. Implementing these solutions will lead to healthier plants and a thriving garden.