Integrated Piping Solutions for Water and Irrigation A 2026 Market Analysis

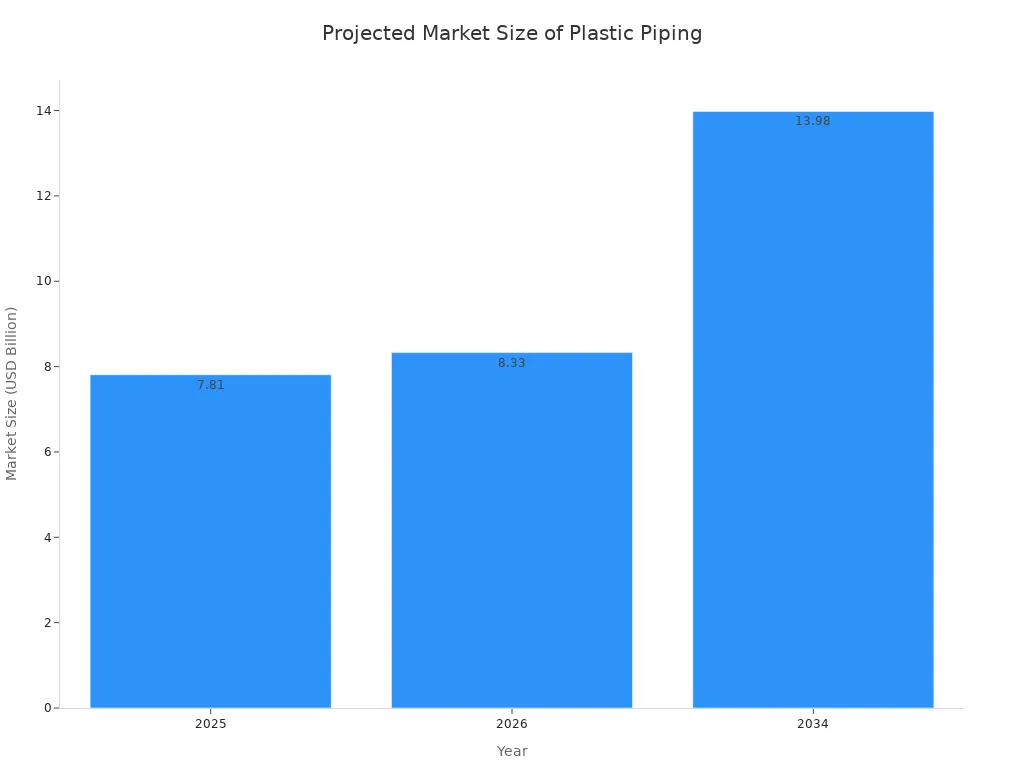

You witness a surging global demand for efficient, sustainable water management. Integrated plastic piping solutions are essential for addressing this challenge. The market trajectory indicates significant expansion. By 2026, the global market size for these solutions will reach an estimated USD 8.33 billion. This growth continues, showcasing the impact of technologies like advanced PP Compression Fitting and versatile CPVC Pipes & Fittings. You can see the projected market growth below:

| Metric | Value |

|---|---|

| Global Market Size (2025) | USD 7.81 billion |

| Projected Global Market Size (2026) | USD 8.33 billion |

| Projected Global Market Size (2034) | USD 13.98 billion |

| CAGR (2026-2034) | 6.68% |

This expansion highlights the crucial role of innovations, including diverse Valve Series and efficient HDPE drainage system components, in shaping the future of water infrastructure.

Key Takeaways

- The global market for integrated plastic piping will reach $8.33 billion by 2026. This shows a big need for better water systems.

- Integrated plastic piping makes water systems last longer. It also makes them easier to install and more cost-effective.

- PP Compression Fittings are very important. They are strong, resist chemicals, and work well in many temperatures. This makes them reliable for water projects.

- New technology makes pipes smarter and stronger. These changes help manage water better and protect the environment.

- Asia-Pacific and Latin America are growing fast in this market. They offer many chances for new water projects.

Understanding Integrated Plastic Piping Solutions

Defining Integrated Water Management Systems

You understand that managing water effectively requires a comprehensive approach. An integrated water management system brings together various elements to ensure sustainable water use. It considers water resource management, looking at how you source and protect water. These systems also address specific purposes and services, like providing clean drinking water or supporting agriculture. You involve different disciplines of knowledge, from engineering to environmental science, to create robust solutions. Government bodies and interest groups play a role in shaping policies, and you engage various stakeholders to ensure everyone’s needs are met.

Specifically, these systems manage several critical components. You handle water supply, which includes getting water from surface and groundwater sources. This involves systems for moving, storing, treating, and distributing water. Understanding water usage helps you evaluate future development impacts. You also manage wastewater treatment, dealing with the water byproduct from homes and industries. These systems prevent water source contamination and increasingly focus on recovering and reusing resources. Stormwater management addresses runoff from rain, which can carry pollutants. This includes traditional infrastructure and green, nature-based solutions. Finally, you prioritize the conservation of existing water sources. Water conservation strategies, including regulations, education, and incentives, are vital for managing both indoor and outdoor water usage.

Core Advantages for Water Supply and Irrigation

Integrated plastic piping solutions offer significant benefits for water supply and irrigation projects. You gain systems that are highly durable and resistant to corrosion, ensuring a long service life. This reduces the need for frequent replacements and maintenance. These solutions also provide excellent flow characteristics, minimizing friction and energy loss. This means you can deliver water more efficiently, saving operational costs.

Installation becomes simpler and faster with plastic piping. Components like PP Compression Fitting allow for quick and secure connections without specialized tools or welding. This ease of installation reduces labor costs and project timelines. You also benefit from the adaptability of plastic pipes. They can handle various pressures and temperatures, making them suitable for diverse applications, from urban water networks to large-scale agricultural irrigation. These advantages contribute to more reliable and cost-effective water management infrastructure.

The Pivotal Role of PP Compression Fitting Technology

You understand that choosing the right materials for water infrastructure is crucial. Polypropylene (PP) compression fitting technology plays a vital role in modern piping systems. These fittings offer unique advantages that make them indispensable for both water supply and irrigation projects worldwide.

Why Polypropylene for Compression Fittings?

You might wonder why polypropylene stands out for compression fittings. Polypropylene offers exceptional material properties. It provides strong impact resistance, preventing breakage from external forces. You can safely use it in temperatures ranging from -40℃ to 60℃, making it suitable even for winter construction. Its flexibility allows for easy connection, disassembly, and recycling. Polypropylene also withstands high temperatures and offers protection against ultraviolet (UV) radiation. You benefit from its inherent pressure resistance and excellent corrosion resistance. The material can also withstand exposure to acids and alkalis, ensuring long-term reliability in plumbing systems.

Polypropylene’s excellent chemical resistance means it performs well against various chemicals and substances. This contributes to its durability, as it withstands diverse environmental conditions, temperature fluctuations, and mechanical stresses. You find it an affordable solution for many plumbing applications. Furthermore, polypropylene’s ability to be recycled supports sustainability and a circular economy.

When you compare polypropylene to other materials, you see its superior long-term cost-effectiveness. PP pipe fittings offer better value than many other plastic and metal options due to their durability and chemical resistance. They require minimal maintenance and replacements, which reduces your overall lifecycle costs. While some metal fittings might have lower initial purchase costs, they are prone to corrosion. This leads to frequent replacements and higher maintenance expenses. PP Compression Fitting technology resists corrosion, making it a more cost-effective solution over time. Compared to other plastics like PVC, PP offers comparable or superior chemical resistance at competitive prices, especially in aggressive chemical environments. High-quality PP fittings may have a higher upfront cost but provide greater long-term value through reduced maintenance and fewer replacements.

Applications and Benefits of PP Compression Fitting in Global Projects

You see PP Compression Fitting technology widely applied in various global water infrastructure projects. It is extensively used for large-scale agricultural irrigation, ensuring efficient water resource management and increasing crop yields. You also find it in urban greening projects, providing durable and reliable irrigation solutions for parks and green spaces. In industrial water systems, these fittings handle corrosive fluids in chemical processing plants. They are also crucial in water treatment facilities, including those for potable water, wastewater, chemical treatment, and seawater desalination. Increasingly, you find them popular in municipal water supply networks, where their impact resistance and durability reduce waste from pipeline ruptures, ensuring stable urban water supply.

The specific performance benefits of using PP Compression Fitting in irrigation systems are significant. You can easily disassemble these fittings, which is particularly beneficial for irrigation applications. Components may need removal and reinstallation seasonally, simplifying maintenance and storage. These fittings are designed to be durable and prevent leaks, crucial for maintaining system integrity in irrigation. They resist UV rays and various chemicals, making them suitable for outdoor agricultural and landscaping applications where exposure to elements is common. Their enhanced UV resistance means they withstand prolonged exposure to sunlight without becoming brittle or degrading, ensuring consistent performance. Polypropylene’s inherent resistance to a wide range of chemicals, including acids, bases, and salts, prevents degradation and corrosion. This leads to a longer service life and reduced maintenance costs compared to metal fittings. The durability and weather resistance of PP Compression Fitting plugs ensure reliable connections in irrigation systems, even under water pressure and various environmental conditions.

Global Market Dynamics: Trends Towards 2026

You observe a dynamic global market for integrated piping solutions, driven by various economic, environmental, and technological forces. These forces shape the industry’s trajectory, creating both challenges and significant opportunities as you look towards 2026.

Key Drivers of Market Growth

Several powerful factors propel the growth of the integrated piping solutions market. You see the energy sector’s expansion as a primary driver. Global oil demand, for instance, could reach 104 million barrels per day by 2026, according to the International Energy Agency. This necessitates extensive, durable pipeline networks, increasing demand for reliable piping systems. Industrial automation also plays a crucial role. As industries like manufacturing and food processing adopt smart technologies, they require sophisticated piping systems that integrate seamlessly with these automated processes. This trend signals a shift towards intelligent, interconnected piping solutions.

You also recognize the impact of environmental regulations. Stricter rules encourage the adoption of recyclable and eco-friendly materials in piping systems. Manufacturers innovate to develop solutions that meet stringent environmental standards and support sustainability goals. This focus on sustainable development and resource efficiency drives innovation in material formulations and product design. You find that using recycled and biodegradable materials aligns with these regulations and consumer preferences.

Furthermore, infrastructure development globally fuels market expansion. Construction projects, including roads, bridges, and urban facilities, are projected to grow at 4.5% annually. This growth increases demand for piping solutions in water supply, sewage, and industrial applications. Finally, a growing focus on water management and conservation acts as a significant driver. The market for water management solutions is expected to grow at a compound annual growth rate of 6.2%. Municipalities and industries invest in advanced piping systems for efficient water distribution and wastewater management, ensuring sustainable water use.

Regional Market Analysis and Opportunities

You identify specific regions as hotspots for market growth and opportunity. The Asia-Pacific region experiences the fastest growth in the flexible pipes market. Expanding industrial activities, particularly in offshore oil and gas exploration and production, along with increasing investments in infrastructure and energy demand, drive this growth. Latin America also shows rapid growth in the pipe fittings market. This comes from expanding infrastructure development and the revitalization of energy and water management sectors. Countries like Brazil, Mexico, and Argentina see significant investments in oil and gas exploration and industrial modernization.

Developing economies present substantial opportunities for integrated piping solutions. You observe rapid industrialization, urbanization, and infrastructure development in these regions. Growth in sectors like oil and gas, water management, chemical processing, and power generation creates high demand. Government incentives and policies promoting infrastructure development further stimulate this market. You also see the adoption of advanced technologies, such as IoT sensors for pipeline monitoring and predictive maintenance, gaining traction. A shift towards sustainable and eco-friendly practices creates demand for modern, efficient, and environmentally compliant piping systems. Emerging regions, including Asia-Pacific, Africa, and Latin America, will contribute significantly to market growth due to their infrastructure investments and industrial expansion. Latin America offers emerging growth potential through infrastructure expansion and rising industrial activity. The Middle East and Africa benefit from growing investments in energy, construction, and smart infrastructure projects.

Innovations and Technological Advancements

You witness continuous innovation in integrated plastic piping systems, enhancing their efficiency and durability. Manufacturers develop advanced polymer blends, creating high-performance plastic formulations. These improve strength, flexibility, and chemical resistance, leading to longer-lasting performance. You also see reinforced and multilayer pipes incorporating materials like fiberglass, aluminum layers, or carbon fiber. These enhance structural integrity and pressure resistance, making pipes more durable in extreme conditions.

The rise of smart piping systems integrates sensors for real-time monitoring of flow rates, leaks, and pressure levels. This helps prevent failures and extends system life. You also find a strong push towards sustainable and recyclable materials, including recycled plastics and biodegradable polymers. These reduce environmental impact while maintaining high durability.

Technological advancements extend to manufacturing and installation. Automated and precision-controlled equipment, such as modern fusion machines with digital controls, ensures precise heating, pressure, and cooling times. This reduces human error and leads to consistent, high-quality joints. These machines also log data for real-time monitoring and quality assurance. Enhanced electrofusion technology uses smart fittings and processors with barcode scanning to set correct fusion parameters, eliminating guesswork. Advances in couplings create stronger, more uniform joints and increase versatility for complex piping systems.

You benefit from improved pipe and fitting materials. Research leads to better polyethylene resins that resist stress, tolerate heat, and endure environmental factors, providing a longer lifespan and improved performance. Non-Destructive Testing (NDT) techniques, like ultrasonic testing, find flaws in fusion joints without cutting the pipe, ensuring every joint meets strict safety and performance standards. Faster heaters and better coolers reduce fusion cycle times, leading to shorter project timelines and cost savings. Future trends include AI and Machine Learning integration for optimizing fusion settings and predicting failures, robotic fusion systems for automation, and smart monitoring with IoT connectivity for real-time feedback.

Material science also drives significant advancements. You see advanced composite materials used in tubing construction for lighter and stronger components. High-strength polymer tubing improves plumbing system reliability and reduces corrosion. Manufacturers utilize recycled materials to minimize environmental impact and develop bio-based polymers that offer comparable performance to traditional plastics while being biodegradable or recyclable. Nanomaterials provide exceptional mechanical properties and chemical resistance, leading to ultra-lightweight yet durable tubing solutions. You also find eco-friendly coatings and surface treatments that minimize frictional losses and improve energy efficiency. These innovations, combined with precision wall thickness, improved resin formulations, and heat fusion welding, ensure consistent performance, UV resistance, and leak-free systems. New manufacturing processes use less energy, and improved pipe smoothness reduces friction loss, lowering operational costs. Innovations like quick-connect fittings and trenchless boring compatibility also make installation faster and easier.

Integrated Solutions in Practice: Case Studies

Large-Scale Agricultural Irrigation Projects

You see integrated piping solutions transforming large-scale agricultural irrigation. These systems optimize water usage and increase crop yields. For example, you find PVC pipes widely used. They are lightweight and easy to cut and join. This significantly reduces installation time and labor costs for extensive irrigation networks. Their adaptability allows for quick adjustments and expansions, crucial for evolving agricultural needs. PVC is also highly resistant to corrosion, abrasion, and chemical degradation. This makes it ideal for harsh agricultural environments. It withstands various soil conditions and exposure to fertilizers and pesticides. This ensures a long service life.

You also see projects using PEX pipes. One farm modernized its irrigation system with PEX. This material offers durability, flexibility, and resistance to UV radiation and agricultural chemicals. The PEX piping led to more efficient water distribution. It reduced water wastage and improved crop health. The pipes’ resilience ensured long-term reliability and minimal maintenance. This highlights their potential for sustainable farming. Commercial vegetable farms using these networks report up to a 30% reduction in water usage. They maintain consistent crop quality. Farms also observe substantial improvements in crop yields due to precise moisture management. You can connect these systems efficiently using a PP Compression Fitting. This ensures leak-free performance and easy maintenance.

Urban Water Distribution Network Enhancements

You also observe significant enhancements in urban water distribution networks through integrated piping solutions. Cities worldwide are upgrading their infrastructure to improve efficiency and reliability.

| City | Enhancement | Specifics |

|---|---|---|

| New York City | Smart Water Meters | Implemented smart water meters across the city to monitor water consumption in real-time, detect leaks, and improve billing accuracy. This initiative has led to significant water savings and reduced operational costs. |

| London | Leak Detection Technology | Utilized advanced acoustic sensors and data analytics to identify and locate leaks in its vast underground water network. This proactive approach has minimized water loss and prevented potential infrastructure damage. |

| Singapore | NEWater Program | Developed a comprehensive water recycling program, NEWater, which treats and purifies used water to a high standard, supplementing its water supply. This innovative approach enhances water security and sustainability. |

| Los Angeles | Water Main Replacement Program | Invested in a multi-year program to replace aging water mains with more durable and corrosion-resistant materials like ductile iron and PVC. This effort aims to reduce pipe bursts, improve water quality, and ensure reliable water delivery. |

| Amsterdam | Pressure Management Systems | Implemented intelligent pressure management systems throughout its water distribution network. By optimizing water pressure, the city has reduced leakage rates, extended the lifespan of its pipes, and lowered energy consumption for pumping. |

New York City, for instance, implemented smart water meters. These meters monitor water consumption in real-time. They detect leaks and improve billing accuracy. This initiative led to significant water savings. London utilized advanced acoustic sensors and data analytics. This technology identifies and locates leaks in its vast underground network. This proactive approach minimizes water loss. Singapore developed its NEWater program. This program treats and purifies used water to a high standard. It supplements the city’s water supply. Los Angeles invested in a multi-year program. It replaces aging water mains with durable materials like ductile iron and PVC. This effort reduces pipe bursts. Amsterdam implemented intelligent pressure management systems. These systems optimize water pressure. They reduce leakage rates and extend pipe lifespan. These examples show how integrated solutions create robust and sustainable urban water systems.

Navigating Challenges and Seizing Opportunities

Overcoming Implementation Hurdles in Integrated Piping

You face several challenges when implementing integrated piping solutions. A primary technical hurdle involves integrating smart pipeline technology with existing infrastructure. Many pipeline networks are decades old. New sensors and monitoring systems may not easily interface with older equipment. This often requires retrofitting existing pipelines. This process is both time-consuming and costly. It may also demand custom solutions and specialized expertise, potentially delaying your project.

You can overcome these hurdles with effective strategies. Consider using automation, such as CNC machining for pipe cutting. This reduces time and improves precision. Automated welding systems also speed up processes while maintaining quality. Real-time monitoring helps track welding parameters and prevents deviations. Modular fabrication and pre-assembly of piping sections off-site improve quality and accelerate on-site installation. This also reduces labor costs and errors. You should also optimize your supply chain. Establish strong relationships with multiple suppliers. Streamline procurement and use vendor agreements. Inventory management systems and Just-in-Time (JIT) delivery prevent material shortages. Invest in a skilled workforce and training programs. Cross-training programs and certification initiatives maintain a skilled team. They can handle complex projects and reduce rework. Implement strict quality control early. This includes real-time inspections and automated quality assurance with AI tools. Meticulous documentation ensures regulatory compliance. Strong project management and communication are also essential. Use daily progress updates and dedicated project managers. Digital platforms facilitate real-time communication among all stakeholders.

Future Growth Avenues for Stakeholders

You will find significant growth opportunities in several areas. The Asia-Pacific region expects the fastest growth. This is due to rapid industrialization, expanding manufacturing bases, and urbanization. China, India, and Southeast Asia are adopting cost-efficient technologies. Latin America also presents emerging opportunities. This comes from infrastructure development and increasing industrial activity. The Middle East and Africa gain momentum from investments in energy, construction, and smart infrastructure.

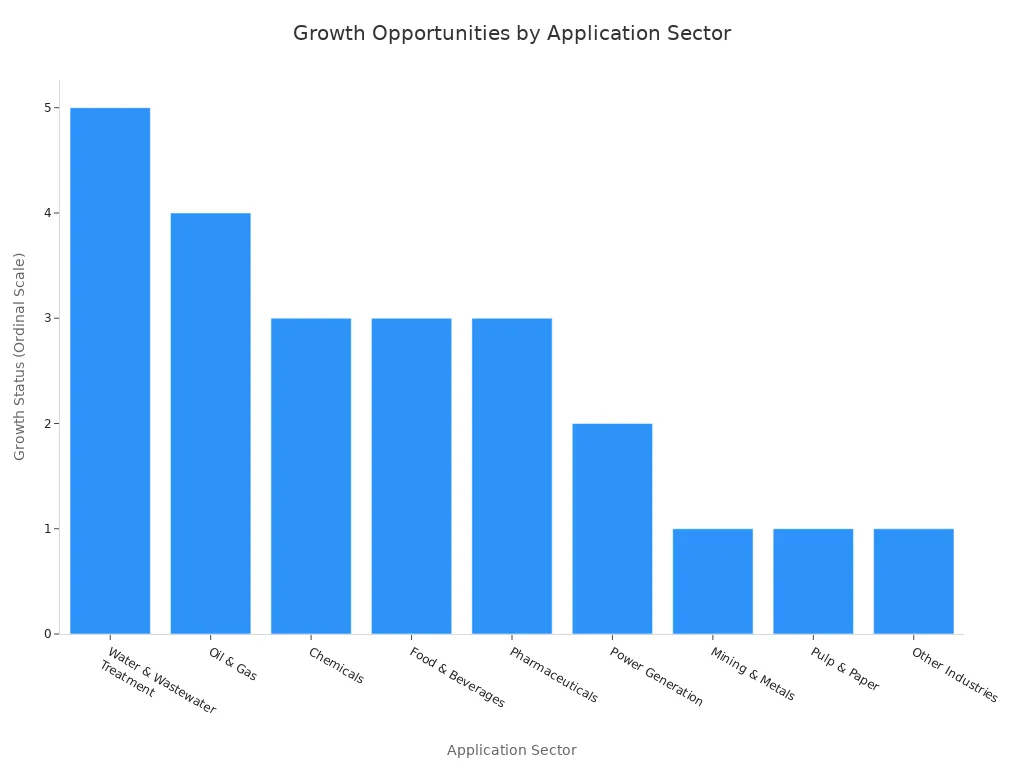

You also see growth across various application sectors:

Strategic partnerships and business models drive future growth. Innovation leads to more flexible and intelligent solutions. Advanced technologies enhance analytics, automation, and integration. Modular and cloud-based models are expanding across industries. Future innovation emphasizes sustainability, security, and compliance. These align technology with responsible resource use, robust data protection, and evolving regulatory requirements. Progressive EPC models, for example, begin with open-book contracts. This fosters transparent collaboration on design and procurement. It builds trust before converting to a firm-lump-sum agreement. Partnership-based risk sharing also moves away from adversarial fixed-price models. It promotes collaborative contracting with shared risk. This is enabled by real-time visibility into design-construction trade-offs, cost drivers, and schedule dependencies.

You see integrated plastic piping solutions are essential for future water infrastructure. The market will grow significantly by 2026. This growth comes from demands for efficiency and sustainability. Robust, adaptable systems have a lasting impact. These systems, including PP Compression Fitting, help address global water challenges. They provide reliable water management for communities worldwide.

FAQ

What are integrated plastic piping solutions?

You use integrated plastic piping solutions to combine different components. They create efficient water supply and irrigation systems. These systems manage water resources from source to use. They include pipes, fittings, and valves.

Why is PP Compression Fitting technology important?

PP Compression Fitting technology offers strong impact resistance. You can use it in various temperatures. It resists corrosion and chemicals. This ensures durable, leak-free connections for your projects.

What are the main advantages of these piping solutions?

These solutions provide durability and corrosion resistance. They offer excellent flow characteristics. You get simpler, faster installation. They adapt to various pressures and temperatures. This leads to reliable, cost-effective water management.

Which regions show the most market growth for these solutions?

The Asia-Pacific region shows the fastest growth. Latin America also presents rapid expansion. These areas have increasing industrial activity and infrastructure development. You find significant opportunities there.

How do integrated piping solutions contribute to sustainability?

You use recyclable and eco-friendly materials. This reduces environmental impact. Advanced polymer blends and smart systems support sustainability goals. They ensure responsible resource use.