How to do when you meet problems on pvc ball valves?

PVC ball valves frequently encounter material degradation and environmental damage. These issues often compromise their structural integrity. Operational and mechanical failures also present common challenges for these components. Furthermore, improper installation and application often lead to significant problems with PVC ball valves.

Key Takeaways

- PVC ball valves face problems from sunlight, chemicals, and extreme temperatures. These issues make the valves weak and cause them to break.

- Valves can fail due to worn-out parts, broken handles, or stuck balls. Regular checks and proper use help prevent these issues.

- Incorrect installation, like over-tightening or poor support, damages PVC ball valves. Always follow instructions and respect pressure limits to avoid leaks and breaks.

Material Degradation and Environmental Challenges for PVC Ball Valves

UV Exposure Damage to PVC Ball Valves

Ultraviolet (UV) radiation from sunlight significantly impacts PVC ball valves. Prolonged exposure causes the material to degrade. This degradation leads to discoloration, becoming chalky, and eventually losing its structural integrity. The valve becomes brittle and prone to cracking, especially under pressure or mechanical stress. This damage compromises the valve’s ability to function reliably outdoors or in areas with direct sunlight.

Chemical Incompatibility Issues with PVC Ball Valves

PVC ball valves exhibit specific chemical resistance properties. However, certain chemicals can cause severe degradation. Moderately polar solvents, such as tetrahydrofuran, corrode PVC. Solvents that soften CPVC, including ethers, ketones, alcohols, esters, and aromatics, also cause structural damage. Concentrated organic solvents like acetone and toluene weaken PVC, leading to softening, cracking, or complete failure. Furthermore, high-concentration sulfuric acid, especially at elevated temperatures, degrades PVC due to its strong oxidizing properties. Higher concentrations and elevated temperatures of sodium hydroxide and potassium hydroxide can affect PVC performance, causing swelling and potential loss of mechanical properties.

Temperature Extremes and Brittleness in PVC Ball Valves

Temperature extremes pose a significant challenge for PVC ball valves. These valves typically operate within a temperature range of 0°C to 60°C (32°F to 140°F). Temperatures exceeding this range can lead to deformation or cracking. When temperatures drop below 0°C (32°F), PVC becomes increasingly brittle and prone to fracture. In extremely cold conditions, the material can crack if water inside the valve freezes and expands. This brittleness compromises the valve’s integrity and operational reliability in cold environments.

Operational and Mechanical Failures of PVC Ball Valves

Seal and O-Ring Wear in PVC Ball Valves

Valve seals, including O-rings, naturally fail as they reach their service life threshold. Corrosive elements within the fluid or gas medium accelerate their degradation. Seal and O-ring wear also occurs when the packing material exceeds its intended usage period, leading to aging and a loss of elasticity. O-rings in PVC ball valves wear over time due to the constant pressure the ball exerts against them. This wear is normal. Replacing worn O-rings and potentially reducing fluid flow intensity extends their lifespan.

Stem Breakage and Stripping in PVC Ball Valves

The stem connects the handle to the ball, controlling its rotation. Excessive force during operation or over-tightening during installation can cause the stem to break or strip. Material fatigue from frequent use also contributes to stem failure. Manufacturing defects in the stem material or design can also lead to premature breakage.

Ball Seizing and Sticking in PVC Ball Valves

Several factors cause the ball within a valve to seize or stick.

- Misalignment or wear of internal components often results from frequent operation, improper installation, or manufacturing defects.

- Environmental conditions, such as extreme temperatures (freezing or high heat), direct sunlight, or corrosive chemicals, affect valve performance.

- Low-quality materials are more susceptible to corrosion, wear, or failure.

- Overuse or incorrect application of the valve beyond its intended purpose contributes to issues.

- Corrosion and rust build-up on metal components occur due to moisture and air exposure.

- Hard water deposits and mineral accumulation form scale, restricting rotation.

- Debris or sediment, like sand or small rocks, gets stuck inside the valve.

- Lack of regular valve maintenance leads to dirt, debris, and friction build-up.

- Seals and gaskets degrade without proper care.

- New valves sometimes exhibit stiffness because factory-fresh PTFE seats are tight against the ball.

- Infrequent use causes seals to stick when left open or closed for extended periods.

Handle Breakage on PVC Ball Valves

Handles on PVC ball valves can break due to several reasons. Applying excessive force to turn a stiff or seized valve often causes the handle to snap. The PVC material itself can become brittle over time, especially with exposure to UV radiation or temperature extremes, making the handle more susceptible to breakage from impact or stress.

Installation and Application-Related Problems with PVC Ball Valves

Over-tightening Damage to PVC Ball Valves

Applying excessive force during installation often damages PVC ball valves. Over-tightening connections can crack the valve body or strip the threads, leading to leaks and premature failure. Installers must apply the proper torque to valve connections to prevent these issues. Using a torque wrench helps achieve the recommended torque value for final tightening. Manufacturers provide specific torque values for their products; always refer to these guidelines. Setting the torque wrench to the correct value ensures secure tightening without over-torquing, which prevents thread damage and guarantees a reliable seal.

Improper Support Stress on PVC Ball Valves

Inadequate support for piping systems places undue stress on PVC ball valves. Misalignment or tension in the piping can cause leaks and premature wear. Installers must ensure valves fit correctly without misalignment or tension. Following manufacturer guidelines for installation, including appropriate fittings and adhesives, helps prevent these problems. Allowing sufficient space for pipe expansion and contraction also prevents stress on the valve and its fittings.

Pressure Limitations Exceeded for PVC Ball Valves

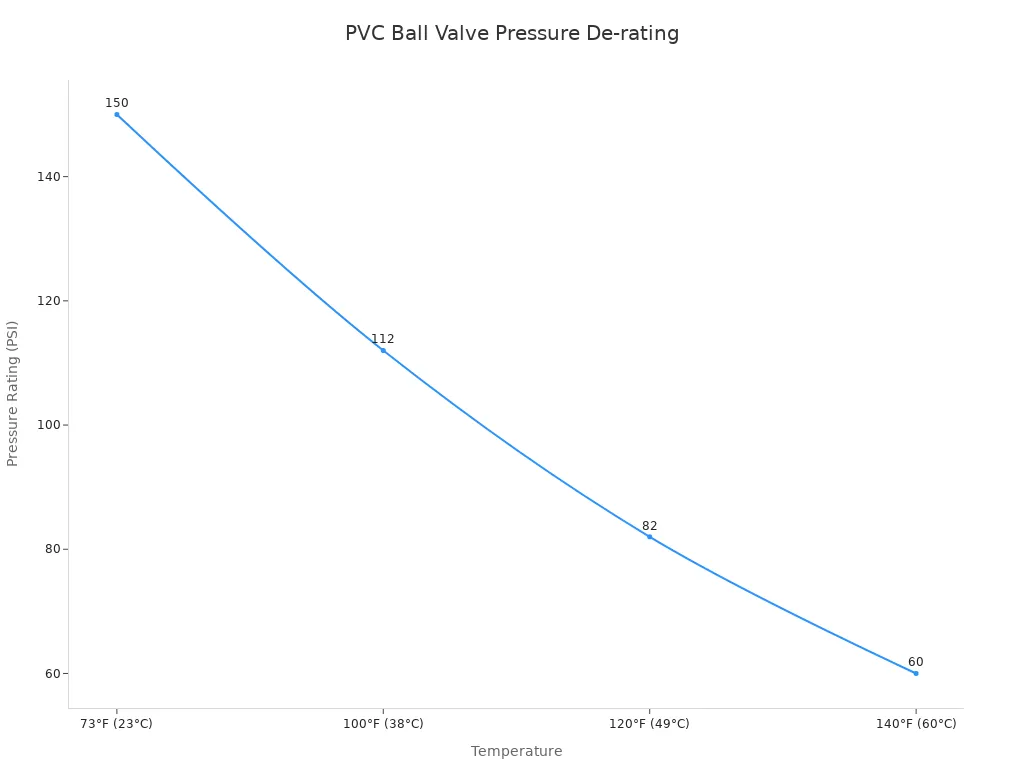

Operating PVC ball valves beyond their specified pressure limits causes significant damage. A standard PVC ball valve typically has a maximum pressure rating of 150 PSI at 73°F (23°C). This pressure rating decreases significantly as the fluid temperature increases, a phenomenon known as the ‘pressure de-rating curve’.

| Temperature (°F/°C) | Pressure Rating (PSI) |

|---|---|

| 73°F (23°C) | 150 |

| 100°F (38°C) | 112 |

| 120°F (49°C) | 82 |

| 140°F (60°C) | 60 |

Monitoring pressure levels during maintenance checks is crucial, as high-pressure spikes can cause valve failures. If pressure surges occur frequently, consider installing pressure relief valves or other mitigation mechanisms.

Debris and Clogging in PVC Ball Valves

Foreign substances entering the pipeline often cause blockages in PVC ball valves. Common causes of clogging include the buildup of organic material, calcium deposits, or other foreign substances that become lodged inside the valve. Dirt, sand, sediment, and general debris also contribute to blockages. Corrosion and scaling, particularly in environments with high mineral or chemical content in the fluid, can further restrict flow and impede valve operation.

Material degradation, operational failures, and installation errors represent the primary challenges for PVC ball valves. Understanding these common problems helps professionals select, install, and maintain these components effectively. Implementing proactive measures can significantly extend the lifespan and reliability of PVC ball valves in various applications.

FAQ

How does UV light damage PVC ball valves?

UV radiation from sunlight degrades PVC material. This causes discoloration, brittleness, and eventual cracking. Such damage compromises the valve’s reliability in outdoor environments.

What temperature range is safe for PVC ball valves?

PVC ball valves typically operate safely between 0°C and 60°C (32°F to 140°F). Temperatures outside this range can lead to material deformation or increased brittleness.

What happens if a PVC ball valve exceeds its pressure rating?

Exceeding the specified pressure limits causes significant damage to PVC ball valves. This can lead to leaks, structural failure, and compromised system integrity.