How long do PVC valves last?

PVC valves typically provide reliable service for 10 to 20 years. This duration often varies significantly based on several conditions. Understanding the specific factors that influence their durability is essential. This knowledge empowers users to maximize the lifespan of their PVC valves. This guide offers insights to help identify when replacement becomes necessary.

Key Takeaways

- PVC valves usually last 10 to 20 years. Their lifespan depends on material quality, how they are used, and if they are installed correctly.

- You can make your PVC valves last longer. Install them properly, check them often, and protect them from sunlight and very cold weather.

- Watch for signs that a PVC valve needs replacing. Look for cracks, leaks, or if it is hard to turn. Also, check for low water flow.

Factors Influencing PVC Valve Lifespan

Several key factors determine how long PVC valves remain effective. Understanding these elements helps users predict valve longevity and implement protective measures.

Material Quality and Manufacturing of PVC Valves

The quality of materials and manufacturing processes significantly impacts valve durability. High-quality PVC valves often use UPVC (Unplasticized Polyvinyl Chloride) for their bodies, a material known for its strength. Manufacturers frequently indicate this on product labels. Internal components also feature robust materials. Valve seats typically consist of resilient substances like PTFE (Teflon), EPDM rubber, or Viton. Packing often uses flexible elastomers or PTFE. Handles, especially for outdoor use, are made from UV-resistant plastics.

Operating Conditions for PVC Valves

The environment where PVC valves operate plays a crucial role in their lifespan. Extreme temperatures pose a significant threat. Standard Schedule 40 PVC valves have a maximum operating temperature around 140°F (60°C). Exceeding this limit drastically reduces material strength and pressure ratings, making valves prone to deformation and failure. Both high and low temperatures can cause thermal expansion or contraction, stressing components and affecting seal integrity. Chemical exposure also presents risks. Certain solvents, such as ketones (e.g., acetone) and aromatic hydrocarbons (e.g., toluene), can compromise PVC’s structural integrity. These substances cause swelling, softening, or even complete material failure.

Installation Quality of PVC Valves

Proper installation is fundamental for maximizing valve lifespan. Valves must fit correctly into the piping system. Installers should avoid misalignments or tension on connections, as these lead to leaks and premature wear. Following manufacturer guidelines is essential, including using appropriate fittings and adhesives. Clean pipe ends and remove burrs before assembly. Use solvent cement for socket connections or ensure threads are properly sealed with Teflon tape. Align the valve with the flow direction. Avoid overtightening connections, which can crack the valve body. Always conduct a pressure test after installation to confirm a leak-free system.

Frequency of Use for PVC Valves

How often a valve operates directly affects its mechanical wear. Frequent cycling generates heat and stresses the sealing components. For ball valves, repeated operation causes wear by shearing microparticles off Teflon seats, eventually leading to leakage. Abrasive particles in the media accelerate this wear, embedding themselves in the Teflon and scoring the ball. Manufacturers optimize torque design to extend operational life. This involves minimizing friction through precision molding and using self-lubricating seats. Proper alignment of the ball and stem assembly prevents uneven wear and jamming.

Exposure to UV Light for PVC Valves

Ultraviolet (UV) light from the sun degrades PVC over time, making it brittle and prone to cracking. Manufacturers often incorporate UV inhibitors during production. Carbon black, for instance, effectively blocks UV components, allowing the valve to maintain its properties outdoors. For existing installations, external protection helps. Heavily pigmented common latex paint or water-based latex paint provides a protective barrier against UV radiation, preventing direct sunlight from reaching the valve’s surface.

Maximizing the Lifespan of Your PVC Valves

Extending the service life of PVC valves involves careful attention to installation, regular upkeep, and environmental protection. Choosing the right valve for the job also plays a crucial role.

Proper Installation Techniques for PVC Valves

Correct installation is paramount for valve longevity. Installers must prepare pipe ends thoroughly, cleaning them and removing burrs. They apply Teflon tape or pipe dope to threads for a secure, leak-free seal. Attaching the valve securely and ensuring proper alignment prevents stress on the system. Avoid common mistakes like skipping primer, overtightening connections, or insufficient curing time. For solvent welding, use the correct applicator size and apply PVC primer and cement properly. Twist parts 90 degrees during joining and hold them for 10-30 seconds. Allow adequate curing time before pressurizing the system.

Regular Inspection and Maintenance of PVC Valves

Consistent inspection helps identify potential issues early. For residential applications, a quick visual check is recommended monthly. Look for cracks, leaks, or signs of wear. Internal inspection and cleaning should occur every 6 to 12 months, or sooner if operational problems arise. These problems include chatter, delayed opening, or small leaks.

Protecting PVC Valves from Environmental Stressors

Environmental factors significantly impact valve durability. To combat UV degradation, apply UV-resistant latex paint or use opaque coverings. Avoid petroleum-based paints. For cold climates, protect PVC valves from freezing. Shut off water to outdoor lines and drain them. Insulate accessible pipes, especially in unheated areas. Consider heat tape or cables for vulnerable pipes. Engineered enclosures with slab-mounted heaters offer the most reliable protection in harsh winter conditions.

Using Appropriate PVC Valves for the Application

Selecting the correct valve type for specific conditions is essential. Schedule 40 PVC is suitable for drainage, irrigation, and cold water systems. Schedule 80 PVC, with its thicker wall, handles higher pressures and industrial applications.

| Feature/Application | Schedule 40 PVC | Schedule 80 PVC |

|---|---|---|

| Wall Thickness | Thinner wall | Thicker wall |

| Pressure Handling | Can handle pressure applications | Designed for higher pressures |

| Typical Applications | Drainage, irrigation, cold water systems | Heavy-duty commercial and industrial applications |

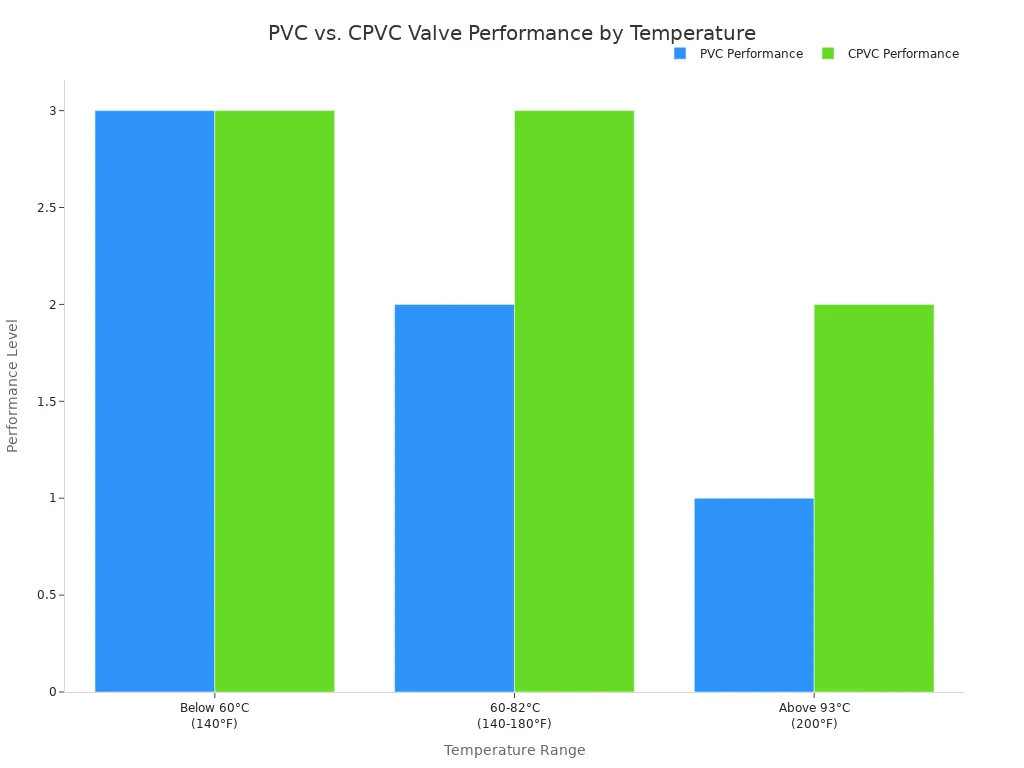

For higher temperatures, CPVC valves are superior. PVC performs well below 140°F (60°C), but CPVC maintains stability up to 200°F (93°C).

This chart illustrates CPVC’s advantage in elevated temperature environments.

Signs Your PVC Valve Needs Replacement

Identifying the signs of a failing PVC valve helps prevent larger plumbing issues. Regular checks can reveal problems before they escalate.

Visible Damage to PVC Valves

Visual inspection often reveals critical issues. Look for cracks on the valve body, deformations, or corrosion. Moisture or leakage around the valve also indicates a problem. Discoloration or yellowing suggests UV degradation. Bulging components or structural deformations signal material degradation from environmental exposure. Severe embrittlement, chalking, or mud-cracking on the surface also point to impending failure.

Leaks from PVC Valves

Leaks are a clear sign a valve needs replacement. Stem packing failure often causes leaks. A bent or misaligned stem can also lead to fluid escape. Loose stem nuts or bolts, improper lubrication, and corrosion contribute to leaks. Exceeding the temperature limit for PVC valves causes material softening and deformation, resulting in significant leaks.

Difficulty Operating PVC Valves

A valve that becomes stiff or difficult to turn indicates internal problems. Mineral buildup from hard water forms scale on internal surfaces, increasing friction. Chemical degradation can cause components to soften or swell. UV degradation also leads to embrittlement, making the valve harder to operate. Debris or sediment stuck inside the valve can also impede movement.

Reduced Flow or Pressure Through PVC Valves

A noticeable drop in water flow or pressure through a specific line suggests a valve issue. Sediment buildup inside the valve can restrict its opening, limiting flow. Clogged pipes due to debris or other obstructions also reduce water passage. Leaks around the valve, even small ones, can indirectly affect the overall system pressure and flow.

The actual lifespan of PVC valves depends heavily on their quality, operating conditions, and consistent maintenance. Regular inspection and proactive replacement are crucial for maintaining an efficient, leak-free plumbing system. Users can ensure these components provide many years of reliable service with proper care and attention.

FAQ

Can you repair PVC valves?

You generally replace PVC valves instead of repairing them. Manufacturers do not design internal components for easy repair. Replacement offers the best long-term solution for issues.

What is the difference between PVC and CPVC valves?

PVC valves suit cold water applications. CPVC valves tolerate higher temperatures, up to 200°F (93°C). Select CPVC for hot water lines or high-temperature industrial uses.

How do you know if a PVC valve is leaking?

Look for these signs:

- Visible water drips or moisture around the valve body.

- A noticeable drop in water pressure.

- Unexplained wet spots near the valve.