How Do You Choose the Best PVC Fittings Valves for PN10 DIN/ASTM Standards in 2026?

You must first understand your application’s specific requirements for PVC Fittings valves. This includes considering the media type and environmental conditions. Always verify compliance with relevant DIN/ASTM standards for PN10 pressure. Carefully evaluate material compatibility and performance under PN10 pressure. Focus on these critical factors. They ensure optimal selection and system reliability.

Key Takeaways

- Understand PN10 pressure ratings. This ensures your PVC system handles 10 bar pressure safely.

- Choose PVC fittings that meet DIN or ASTM standards. These standards guarantee quality and compatibility.

- Select the right PVC material. uPVC works for cold water, and cPVC works for hot water.

- Use proper installation methods. This includes correct connections and support. This prevents leaks and damage.

- Perform regular inspections and maintenance. This extends the life of your PVC system.

Understanding PN10 Pressure Rating for PVC Fittings Valves

Defining PN10 for PVC Valve Applications

You often see “PN10″ on valves and pipes. PN stands for Pressure Nominal. It tells you the maximum working pressure a pipe or valve can safely handle. This pressure rating is always specified at a temperature of 20°C. For PN10, this means the component can withstand 10 bar of pressure. This is approximately 145 PSI or 1.0 MPa. When you see “PN10″ on a PVC valve, it means the valve is rated for a nominal pressure of 10 Bar. Given that 1 Bar is roughly 14.5 PSI, a PN10 valve is approximately equivalent to a 145 PSI valve. You must always consider both the pressure number and any associated temperature rating for a complete understanding.

Importance of Adhering to PN10 for System Integrity

Adhering to the PN10 rating is critical for your system’s integrity. You prevent costly failures when you select the correct pressure rating. Using a valve rated lower than your system’s operating pressure can lead to leaks. It can also cause catastrophic ruptures. This ensures your entire piping system operates safely and efficiently. You also extend the lifespan of your components. Proper PN10 selection guarantees reliable performance over time.

Common Applications Requiring PN10 PVC Fittings Valves

Many common applications require PN10 PVC Fittings valves. You will find them in residential water supply lines. They are also essential for irrigation systems. Light industrial processes often use them for water and non-hazardous fluid transport. These applications typically involve moderate pressure. PN10 valves provide the necessary strength and durability for these everyday uses. You can confidently install them in systems where consistent pressure is a factor.

Navigating DIN Standards for PVC Fittings Valves

Overview of Relevant DIN Standards for PVC Fittings Valves

You need to understand DIN standards when you select PVC fittings valves. DIN stands for Deutsches Institut für Normung, or the German Institute for Standardization. These standards ensure quality and compatibility for products, especially in European markets. They provide specific guidelines for materials, dimensions, and testing. For PVC valves, DIN standards help guarantee that products meet certain performance criteria. You find these standards crucial for consistent manufacturing and reliable system integration.

Specific DIN Requirements for PN10 Pressure Ratings

DIN standards define precise requirements for PN10 pressure ratings. They specify how manufacturers must test valves to ensure they can safely handle 10 bar pressure at 20°C. These requirements cover material composition, wall thickness, and overall valve design. A valve that meets DIN PN10 standards has undergone rigorous testing. This testing confirms its ability to withstand the specified pressure without failure. You can trust these valves for applications requiring this pressure level.

Ensuring Compliance with DIN Specifications for PVC Fittings

You must ensure your chosen PVC fittings valves comply with DIN specifications. Always look for clear documentation from the manufacturer. This documentation should state the valve meets relevant DIN standards. Certifications from third-party bodies also confirm compliance. For example, Donsen products often carry CE certification. This certification indicates adherence to European safety and performance standards, which frequently align with DIN. Choosing compliant products guarantees system safety and long-term performance.

Navigating ASTM Standards for PVC Fittings Valves

Overview of Relevant ASTM Standards for PVC Fittings Valves

You also need to understand ASTM standards when selecting valves. ASTM International develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. These standards are widely recognized, especially in North America. They provide crucial guidelines for the design, manufacturing, and testing of PVC products. For example, ASTM F1970-12 specifies requirements for special engineered fittings, appurtenances, or valves. These are designed for use in Poly (Vinyl Chloride) (PVC) or Chlorinated Poly (Vinyl Chloride) (CPVC) systems. This standard covers testing, materials, dimensions, workmanship, marking, and in-plant quality control. It applies to products used with pressurized liquids. Another important standard is ASTM D2665, which is relevant for PVC DWV (Drain, Waste, Vent) fittings. These standards ensure your PVC components meet specific quality and performance benchmarks.

Specific ASTM Requirements for PN10 Pressure Ratings

ASTM standards do not typically use the “PN10″ designation directly. Instead, they specify pressure ratings in PSI (pounds per square inch) or MPa (megapascals). You will find these ratings linked to specific temperatures. For example, a PVC valve might be rated for 150 PSI at 73°F (23°C). This rating is comparable to a PN10 rating. ASTM standards outline rigorous testing procedures. These tests confirm a valve’s ability to withstand specified pressures without failure. They ensure the material integrity and structural soundness of the valve under operational conditions. You must match the ASTM pressure rating to your system’s maximum operating pressure.

Ensuring Compliance with ASTM Specifications for PVC Fittings

You must ensure your chosen PVC Fittings valves comply with ASTM specifications. Always request documentation from the manufacturer. This documentation should clearly state which ASTM standards the product meets. Look for third-party certifications. These certifications provide independent verification of compliance. Donsen, for instance, holds NSF certification in the USA. This certification indicates adherence to strict public health standards, often incorporating ASTM requirements. Choosing ASTM-compliant products guarantees reliability and safety for your system.

Comparing DIN and ASTM Standards for PN10 PVC Fittings Valves

Key Differences Between DIN and ASTM for PVC Fittings

You will notice distinct differences between DIN and ASTM standards. DIN, from Germany, focuses on European markets. It often uses metric measurements. DIN standards can be very specific about dimensions and material composition. ASTM, from the United States, serves North American markets. It typically uses imperial measurements like PSI. ASTM standards often focus on performance requirements. They allow more flexibility in design if the product meets performance tests. Different testing methods and certification bodies also distinguish them.

Similarities and Overlaps in PN10 Requirements

Despite their differences, DIN and ASTM standards share common goals. Both aim to ensure safe and reliable pressure handling. They both emphasize material quality. They also focus on product durability. A PN10 rating in DIN roughly translates to a specific PSI rating in ASTM. This equivalence applies at a standard temperature, usually 20°C or 73°F. Both sets of standards ensure the product can withstand operational pressures without failure. They both prioritize system integrity.

Strategies for Selecting Dual-Standard Compliant PVC Fittings Valves

You can select dual-standard compliant PVC Fittings valves. Look for manufacturers who offer products with multiple certifications. For example, Donsen products often carry both CE (European) and NSF (USA) certifications. This indicates compliance with both regional standards. Always check the manufacturer’s specifications. They should clearly state adherence to both DIN and ASTM. Consult with your supplier. They can guide you to products suitable for your specific project requirements. Consider your project’s location. Local regulations often dictate which standard you must follow.

Material Selection for PN10 PVC Fittings Valves

You must carefully select the right material for your PN10 PVC fittings valves. This choice directly impacts your system’s performance and longevity. Understanding the properties of different PVC types helps you make an informed decision.

Assessing uPVC and cPVC for PN10 Applications

You will primarily encounter two types of PVC for piping systems: uPVC and cPVC. Each offers distinct advantages for PN10 applications.

- uPVC (unplasticized Polyvinyl Chloride): This material is rigid and strong. It does not contain plasticizers, which makes it very stiff. You find uPVC widely used for cold water applications. It performs exceptionally well under PN10 pressure ratings at ambient temperatures. Its cost-effectiveness and excellent flow characteristics make it a popular choice for many water supply and irrigation systems.

- cPVC (chlorinated Polyvinyl Chloride): Manufacturers chlorinate cPVC to enhance its temperature resistance. This means cPVC can handle higher operating temperatures than uPVC. If your PN10 application involves warm or hot fluids, cPVC becomes the superior option. It maintains its structural integrity and pressure rating even at elevated temperatures. You often see cPVC in industrial processes or hot water distribution systems where uPVC might not suffice.

You should assess your specific temperature requirements. This helps you decide between uPVC and cPVC for your PN10 system.

Chemical Resistance and Temperature Considerations for PVC Fittings

You need to consider the chemical resistance of your PVC fittings. This is crucial for the media your system transports. PVC exhibits excellent chemical resistance. It is ideal for wastewater management systems. You find it highly resistant to acids like sulfuric acid and hydrochloric acid. It also resists alkalis such as sodium hydroxide. PVC can withstand various organic compounds. This makes it suitable for municipal sewage and industrial wastewater.

However, you must also be aware of its limitations. Certain solvents can adversely affect PVC’s structural integrity. These include ketones (e.g., acetone) and aromatic hydrocarbons (e.g., toluene). They can lead to swelling, softening, or even failure. Elevated temperatures can also alter PVC’s properties. They accelerate degradation when exposed to aggressive chemicals. Always verify the compatibility of your PVC fittings with the specific chemicals and temperatures in your application.

Durability and Longevity of PVC Fittings Materials

You want your piping system to last. PVC materials offer impressive durability and longevity. PVC pipe fittings exhibit good anti-aging capabilities. They are durable, with a lifespan of up to 50 years under normal service conditions. Many PVC fittings are designed for a long life, exceeding 50 years under normal operating conditions.

For example, PVC saddle clamps, with proper installation and maintenance, typically last between 15 to 30 years. Key factors influence their life expectancy. These include material quality and operating pressure. Saddle clamps designed for PN10/PN16 working pressure are built to handle typical water distribution and sewage system pressures. This ensures long-term reliability. You can expect a robust and enduring system when you choose high-quality PVC materials.

Types of PVC Fittings Valves and Their PN10 Suitability

You need to understand the different types of valves available for your PN10 PVC systems. Each valve type serves a specific function. Choosing the right one ensures efficient and reliable fluid control.

Ball Valves for PN10 PVC Fittings Systems

You will find ball valves are a popular choice for many PN10 PVC systems. A PN10 PVC ball valve has a polyvinyl chloride body. It contains a spherical ball with a central bore. A handle allows you to control it manually. This design provides quick shut-off and precise flow regulation. Manufacturers engineer these valves to operate within a temperature range of 5 ℃ to 95 ℃. They undergo rigorous testing for high-pressure applications. They often feature flanged ends for secure installation. These valves can withstand pressures up to 150 PSI. This meets the demands of modern piping systems.

Consider the advantages of PVC ball valves over metal alternatives:

| Advantage | PVC Ball Valves | Metal Ball Valves |

|---|---|---|

| Corrosion Resistance | Excellent, ideal for corrosive environments | Poor, prone to rust and corrosion |

| Weight | Lightweight, easy to handle | Heavy, requires more support |

| Cost | Generally more affordable | More expensive |

| Durability | Durable with proper maintenance | Can corrode over time |

| Versatility | Suitable for various applications | Limited to specific uses |

PVC ball valves offer a compact design. This allows them to fit in smaller spaces. They are easy to operate with quarter-turn handles. These handles can also partially open the valve. They are made from corrosion-resistant PVC material. Wetted surfaces contain less than 0.25% lead content. Their large ports allow for greater flow. This results in minimal pressure drop or turbulence. You can use them for various media. This includes water, air, and corrosive chemicals. PVC is a cost-effective material. This makes these valves more affordable than other plastics. True union valves allow for easy removal. This makes inspection and cleaning simple.

You can also achieve significant cost savings with PVC ball valves. For example, a PVC 3-Way Pneumatic Ball Valve costs $300-800. A metal equivalent costs $600-1,500. This means PVC options are 40-60% less expensive. Installation costs are also lower. PVC valves are 40-50% lighter. This reduces labor.

| Valve Type | Size | Approximate Weight (pounds) |

|---|---|---|

| Plastic Valve | 1/2-inch | 0.1 – 0.2 |

| Stainless Steel Valve | 1-inch | 1 – 2 |

| Cast Iron Valve | 2-inch | 5 – 10 |

| Material | Density (kg/m³) |

|---|---|

| PVC | 1,400 |

| Carbon Steel | 7,850 |

| Stainless Steel | 8,000 |

| Brass | 8,500 |

PVC ball valves are much lighter than metal alternatives. Their lower material density reduces labor and installation costs. It also simplifies transportation and handling. These valves offer substantial long-term cost savings. This comes from reduced maintenance and an extended operational life. Their inherent corrosion resistance means you do not need frequent treatments or repairs. Metal valves often require these. This contributes to a longer lifespan. It also minimizes disruptions to fluid supply systems.

Butterfly Valves for PN10 PVC Fittings Systems

You might choose butterfly valves for larger pipelines. They use a rotating disc on a shaft to control fluid flow. Their compact design handles high fluid volumes effectively. Concentric butterfly valves typically have a maximum pressure rating of PN10 or PN16. This limitation comes from the soft seat material and overall valve design. You can use them for coarse flow regulation. They offer reasonable throttling characteristics between approximately 40° and 90° open. For precise flow modulation, a purpose-designed control valve is better. Their soft-seated design, easy operation, and cost advantages make them a preferred choice. This applies to water-related applications. Examples include municipal water supply and HVAC systems. They ensure reliable performance and long service life. You must correctly match seat material and pressure/temperature conditions.

For instance, ERA Valves offers a PVC Butterfly Valve, model UBV01. It has a PN10 rating (F1970). It also holds NSF-pw & UPC certifications. This valve features a full port design. This maximizes flow and minimizes pressure drop or turbulence. You can install it on Schedule 40 or 80 PVC pipe. It suits distributing pressurized liquids. These liquids must be chemically compatible with piping materials. You can find them in water parks, fountains, aquariums, and light-duty chemical and wastewater applications.

Here are some specific benefits of butterfly valves:

- Compact and lightweight design

- Suitable for large volume flow control

- Easy to install and operate

- Cost-effective and energy-efficient

General PVC valve benefits also apply:

- Corrosion resistance: Highly resistant to rust, chemicals, and corrosive elements.

- Lightweight and easy to install: Reduces labor costs and installation time.

- Cost-effective: More affordable than metal or stainless steel valves.

- Durability and longevity: Resistant to wear and tear, providing a long-term solution.

Consider these specifications for a typical PVC butterfly valve:

| Specification | Detail |

|---|---|

| Body Materials | UPVC, CPVC, or PPH |

| Connection Type | Flanged |

| Pressure Rating | 10 bar |

| Structure Type | Midline Structure A Type |

| Sealing Materials | EPDM or FKM |

| Stem Material | Stainless Steel |

| Application Medium | Water, seawater, wastewater, chemical, etc. |

| Operating Temperature | -20℃ to 80℃ |

These valves feature a UPVC body and disc. This provides chemical and corrosion resistance. They withstand acids, alkalis, salts, oils, and solvents. Pneumatic piston or diaphragm actuators offer reliable air-powered automation. They do not require electricity. You can find them in single-acting and double-acting configurations. Modulating control enables accurate throttling. It also provides repeatable flow regulation. Positioners are available for precise control. A high close-off pressure rating ensures reliable shut-off. It also minimizes seat leakage. Their compact, lightweight design facilitates easy installation and maintenance. They are designed for a long service life. This includes millions of duty cycles and minimal maintenance.

Check Valves for PN10 PVC Fittings Systems

You use check valves to prevent backflow in your piping system. They allow fluid to flow in only one direction. This protects pumps and other equipment from damage. They are available in various materials. These include PVC, CPVC, PP, and PVDF. This ensures compatibility with many systems. This includes PN10 PVC Fittings. These valves offer a robust solution. They have a pressure rating up to 235 PSI at 70°F (16 Bar at 21°C) non-shock. This exceeds the PN10 requirement. PN10 is approximately 145 PSI or 10 Bar.

You can install check valves horizontally or vertically. They feature a square cut seat. This provides positive sealing. It also ensures seating with minimum back pressure. Larger sizes, from 1/2″ to 6″, use a Sure Block design. Smaller sizes, 1/4″ and 3/8″, feature a Trim Check design. You have options for end connections. These include Socket, Threaded, or Flanged. This offers flexibility for integration into different piping systems. Their primary design ensures versatile and reliable backflow prevention. This is crucial in critical flow control applications. You can also get foot valve screens as an added option.

Other Valve Types and Their PN10 Applicability in PVC Fittings

You will encounter several other valve types beyond ball, butterfly, and check valves. Each offers unique advantages for specific applications within PN10 PVC systems. Understanding these options helps you select the best valve for your needs.

Gate Valves

You use gate valves primarily for on/off service. They are not ideal for throttling or regulating flow. A gate valve operates by lifting a wedge-shaped gate out of the fluid path. When fully open, it provides a full bore flow. This results in minimal pressure drop. This makes them suitable for systems where you need an unobstructed flow. For PN10 PVC systems, you can find gate valves made from PVC. They are effective for isolating sections of a pipeline. However, their slow operation means they are not suitable for applications requiring quick shut-off. You typically see them in water distribution lines or irrigation systems where they remain open or closed for extended periods.

Globe Valves

You choose globe valves when you need to regulate or throttle fluid flow. They feature a movable disc and a stationary ring seat. The fluid flow changes direction multiple times within the valve body. This design allows for precise flow control. However, this also causes a higher pressure drop compared to gate or ball valves. For PN10 PVC systems, PVC globe valves are available. They are excellent for applications where you need to control flow rates accurately. You might use them in process control systems or where you need to adjust flow to specific equipment. Their ability to modulate flow makes them valuable despite the increased pressure loss.

Diaphragm Valves

You select diaphragm valves for applications involving corrosive, abrasive, or viscous fluids. They use a flexible diaphragm to control flow. This diaphragm isolates the fluid from the valve’s operating mechanism. This design prevents contamination of the fluid and protects the valve’s internal components. PVC diaphragm valves are highly resistant to many chemicals. They are suitable for PN10 applications in chemical processing, wastewater treatment, and pharmaceutical industries. They offer excellent sealing capabilities. However, they typically have lower pressure and temperature limits compared to other valve types. You must ensure the diaphragm material is compatible with your specific media and operating conditions.

Plug Valves

You might also consider plug valves. They use a cylindrical or tapered plug with a bore through it. You rotate the plug a quarter turn to open or close the valve. Like ball valves, they offer quick on/off operation. They can also be used for throttling in some designs. PVC plug valves are available for PN10 systems. They are often chosen for applications where you need tight shut-off and minimal maintenance. Their simple design makes them robust.

You must always verify that any valve type you choose meets the PN10 pressure rating. This ensures the integrity and safety of your PVC Fittings system.

Seal and Gasket Materials for PN10 PVC Fittings Valves

Compatibility with PN10 Pressure and Media

You must choose seal and gasket materials carefully. They ensure your PN10 PVC system works correctly. These materials must withstand 10 bar pressure. They also need to resist the specific media flowing through the system. Consider the fluid’s chemical composition. Also, think about the operating temperature. Incompatible materials can lead to leaks. They can also cause system failure.

Common Seal Materials for PVC Fittings Valves

Several materials commonly serve as seals in PVC valves. EPDM (Ethylene Propylene Diene Monomer) is a popular choice. It offers excellent resistance to water, steam, and many chemicals. FKM (Fluoroelastomer), often known as Viton, provides superior chemical and high-temperature resistance. NBR (Nitrile Butadiene Rubber), or Buna-N, works well with oils and hydrocarbons. You select the best material based on your application’s specific needs. Each material ensures reliable sealing under PN10 conditions.

Ensuring Long-Term Sealing Integrity in PVC Fittings

You want your piping system to last. Ensuring long-term sealing integrity is vital. First, clean all interfaces thoroughly. Contamination causes inadequate sealing and leaks. When retrofitting, clean old pipes and fittings. This prevents contaminants from compromising new valve effectiveness. Second, ensure proper orientation. Installing a valve backward or upside down causes operational inefficiencies. It can also lead to potential failure. Always follow manufacturer specifications for flow direction. Third, account for thermal expansion. Thermoplastic materials expand and contract significantly with temperature changes. Design systems with flexibility. Incorporate expansion joints or loops. This manages stress and prevents leaks or structural failure.

You should also select the right sealant materials. Use solvent cements specifically formulated for PVC. These chemically soften surfaces for a strong bond. For flexibility, consider silicone or rubber-based sealants. Ensure compatibility with PVC. Proper installation techniques are also key. Ensure pipe and fitting surfaces are clean and free of debris. Follow manufacturer instructions for solvent cement application. Ensure even coverage. Allow adequate curing time before applying pressure. Typically, allow 24 hours for solvent cement to cure. Regularly inspect connections for leaks or damage. This is especially important in high-pressure or high-temperature applications. Promptly repair or replace affected PVC Fittings to extend the system’s lifespan.

End Connection Options for PN10 PVC Fittings Valves

You must choose the right end connection for your PN10 PVC systems. This decision impacts installation ease, system integrity, and future maintenance. Different connection types offer distinct advantages. You select the best option based on your specific application needs.

Threaded Connections for PVC Fittings

You can use threaded connections for your PN10 PVC systems. These connections feature threads on the pipe and the fitting. You screw them together. This method allows for easy assembly and disassembly. You often find them in smaller diameter pipes. They are useful where you need to remove sections for maintenance. Always use a suitable thread sealant, like PTFE tape. This prevents leaks. Without proper sealing, threaded connections can be prone to drips. They are generally not recommended for applications with high vibration or stress. You must ensure threads are clean before assembly.

Socket Connections for PVC Fittings

You will often use socket connections, also known as solvent weld connections. This method creates a very strong and permanent bond. You apply a special solvent cement to both the pipe and the inside of the fitting. The cement chemically fuses the PVC surfaces. This creates a single, continuous piece. Socket connections are highly reliable for PN10 pressure. They offer excellent leak-proof performance. You must allow adequate curing time for the cement. This ensures the joint reaches full strength. Once joined, you cannot easily disassemble these connections. This makes them ideal for permanent installations.

Flanged Connections for PVC Fittings

You should consider flanged connections for larger diameter pipes or when connecting to different materials. Flanges are flat, circular plates. You bolt them together with a gasket in between. This creates a secure and robust seal. Flanged connections allow for easy removal of valves or pipe sections. This is beneficial for maintenance or system modifications. They provide a very strong joint suitable for PN10 applications. However, they are more bulky than other options. They also require more hardware, such as bolts and gaskets. You must tighten bolts evenly to ensure a proper seal. This prevents uneven stress and potential leaks.

Impact of Connection Type on PN10 Integrity of PVC Fittings

You must understand how each connection type affects the PN10 integrity of your PVC fittings. The connection method directly influences the system’s ability to maintain its rated pressure. Choosing the correct type and installing it properly ensures your system operates safely and efficiently.

Threaded connections, while convenient for assembly, require careful attention to maintain PN10 integrity. You must use an appropriate thread sealant, like PTFE tape or pipe dope, to prevent leaks. Without proper sealing, these connections can become weak points. They may not hold the full 10 bar pressure. Over-tightening can also stress the PVC, leading to cracks and compromising the PN10 rating. Always follow manufacturer guidelines for torque specifications.

Socket connections offer superior PN10 integrity. When you use solvent cement, it chemically fuses the pipe and fitting. This creates a monolithic joint. This joint becomes as strong as, or even stronger than, the pipe itself. This method provides excellent resistance to pressure and leaks. It ensures the system maintains its PN10 rating effectively. However, you must allow sufficient curing time for the cement. Rushing this process can weaken the joint.

Flanged connections are robust for maintaining PN10 integrity, especially in larger diameter systems. They allow for strong, bolted joints that can withstand significant pressure. The key to their success lies in proper gasket selection and even bolt tightening. An incorrect gasket or uneven tightening can lead to leaks. This compromises the PN10 rating. Flanges also allow for easy disassembly. This is beneficial for maintenance without sacrificing pressure integrity when reassembled correctly.

Ultimately, the integrity of your PN10 PVC system depends on the connection type and your installation practices. Each method has specific requirements. Adhering to these ensures your system performs as expected.

Tip: Always consult the manufacturer’s installation guides for specific instructions on each connection type. This ensures optimal PN10 integrity.

Supplier Evaluation and Certifications for PVC Fittings Valves

You must carefully evaluate your supplier. This ensures you get reliable PVC fittings valves. Checking certifications and reputation helps you make smart choices.

Importance of Manufacturer Reputation for PVC Fittings

You should always consider a manufacturer’s reputation. A company with a long history often produces high-quality products. They have proven their reliability over time. For example, manufacturers with over 20 years of experience in plastic pipelines understand the industry well. They specialize in water supply and irrigation systems. Such experience means they know how to make durable PVC fittings. A strong reputation indicates consistent product quality and good customer support. You can trust products from well-known manufacturers.

Third-Party Certifications (e.g., CE, NSF, WRAS) for PVC Fittings

You need to look for third-party certifications. These certifications confirm that products meet specific standards. They give you confidence in the valve’s quality and safety. Here are some key certifications to check:

- NSF 61: This ensures the product is safe for drinking water. It confirms the product is free from lead and heavy metals.

- WRAS: This certification is important for potable water approvals, especially in the UK.

- FDA: This indicates the product meets food-grade compatibility standards.

- CE: This shows general compliance with European standards.

- RoHS: This certification means the product restricts hazardous substances.

- REACH: This relates to the registration, evaluation, authorization, and restriction of chemicals.

- ISO 9001: This is a quality management system certification.

- ISO 14001: This shows environmental management system compliance.

- UPC: This certification is common for plumbing products in the USA.

Many reputable manufacturers hold multiple certifications. For instance, some companies have CE, NSF, WRAS, and other global certifications. This shows their commitment to international quality.

Assessing Quality Control and Manufacturing Processes for PVC Fittings

You should also assess a manufacturer’s quality control. Good manufacturers use high-quality raw materials. They often import these materials to ensure product quality. They also use advanced production lines. This includes fiberglass production lines or efficient double production lines. These processes help ensure consistent product quality. A manufacturer with strict quality control will produce reliable PVC fittings valves. They test their products thoroughly. This guarantees the valves meet PN10 DIN/ASTM standards.

Installation Best Practices for PN10 PVC Fittings Valves

Proper Handling and Assembly Techniques for PVC Fittings

You must handle PVC fittings with care. Avoid dropping or dragging them. This prevents damage to their surfaces. Before assembly, ensure all pipe ends are clean and free of debris. Use a fine-toothed saw or pipe cutter. This creates a straight, clean cut. Deburr and chamfer the pipe edges. This removes sharp areas. It also prevents damage to seals during insertion. Always align fittings correctly. This ensures a smooth, stress-free connection.

Maintaining PN10 Rating During Installation of PVC Fittings

You must maintain the PN10 rating during installation. Follow the manufacturer’s instructions precisely. For solvent weld connections, apply the correct primer and solvent cement. Ensure full coverage on both pipe and fitting surfaces. Insert the pipe fully into the fitting socket. Give it a slight twist for a secure bond. Allow adequate curing time before you pressurize the system. For threaded connections, use appropriate thread sealant. Do not over-tighten. This can crack the PVC. For flanged connections, use the correct gasket. Tighten bolts evenly. This creates a leak-proof seal.

Avoiding Common Installation Errors with PVC Fittings Valves

You can avoid common installation errors. This ensures your PVC fittings valves perform reliably.

- Over-tightening During Installation: You apply excessive force. This can cause cracks in the PVC material. It distorts the valve body. This leads to premature failure and leaks. Use correct tools and techniques. This creates a secure, leak-free connection without over-tightening. Ensure proper alignment of valves with the piping system. This prevents stress.

- Improper Support and Stress: Inadequate support leads to shifting. This stresses valve components. It causes leaks, especially near connection points. Stress cracking in PVC fittings can also occur. Sagging due to thermal expansion or contraction can happen. Adequately support the piping system. This is particularly important for larger or heavier systems. It prevents bending or twisting forces. Regularly verify pipe supports. Ensure the valve is correctly positioned. Pipes must be aligned and supported before you tighten fittings.

- Poor Pipe Preparation: Rough, burr-filled pipe edges can damage the valve seal during installation. Cut pipes to required lengths. Use a fine-toothed saw or pipe cutter. This ensures smooth, burr-free edges. Deburr and chamfer pipe edges. This removes sharp areas. It prevents damage.

- Incorrect Bonding: Improper application of primer and solvent cement leads to weak bonds and leaks. Use appropriate CPVC primer and solvent cement. Apply primer to both pipe and valve connection surfaces. Then apply cement. Insert the pipe into the valve socket with a slight twist. This creates a secure bond.

- Lack of System Preparation and Testing: Installing without depressurizing or failing to test for leaks leads to immediate issues or future failures. Depressurize the piping system before installation. Perform a pressure test after installation. This checks for leaks. Inspect all connections and the valve. Test the system under pressure before full operation.

- Poor Accessibility and Misalignment: Installing valves in inaccessible locations or with misalignment hinders operation. It also causes stress. Install the valve in an accessible location. Ensure the handle has enough space to turn freely. Avoid misalignment during installation. This prevents unnecessary stress on the valve.

- Temperature Exposure: Exposing PVC to temperatures beyond its design limits weakens the valve. Freezing water in colder climates can crack the valve body. Do not expose PVC to temperatures beyond its design limits. In colder climates, insulate to prevent freezing water from cracking the valve body.

Maintenance and Longevity of PN10 PVC Fittings Valves

You ensure the long-term performance of your PN10 PVC system through diligent maintenance. Proper care extends the life of your fittings and valves. This also prevents unexpected failures.

Routine Inspection Protocols for PVC Fittings

You must regularly inspect your PVC fittings. This prevents costly repairs. A quick visual check every few months helps. Look for cracks, discoloration, or loose connections. Address problems immediately. For larger systems, professional monitoring tools track water pressure and flow rates. This detects hidden leaks or blockages. It ensures the system runs smoothly.

For PN10 PVC fittings, you follow specific protocols:

- Visual Inspection: Check for a uniform cement bead around the entire joint circumference.

- Pressure Testing: Test systems at 1.5 times operating pressure for a minimum of 2 hours.

- Leak Detection: Utilize a soapy water solution to identify any minor leaks during testing.

- Regular Inspections: During routine maintenance, check for signs of stress, discoloration, or joint movement.

- Support Verification: Ensure pipe supports remain secure and properly spaced.

- System Monitoring: Track pressure and flow rates to identify developing problems before failure occurs.

Extending Lifespan Through Proper Maintenance of PVC Fittings

You extend the lifespan of your PVC fittings by addressing issues promptly. Regular maintenance prevents small problems from becoming big ones. You ensure proper support for all piping. This prevents stress on joints and valves. You also protect exposed PVC from direct sunlight. UV radiation can degrade the material over time. Proper insulation in cold climates prevents freezing. Freezing water can crack PVC components. You keep the system clean. This avoids blockages and maintains optimal flow.

Troubleshooting Common Issues with PN10 PVC Fittings Valves

You might encounter common issues with your PN10 PVC fittings valves. Leaks are a frequent problem. You first check all connections. Ensure they are tight and properly sealed. If you find a leak at a solvent-welded joint, you may need to cut out the section and re-weld it. For threaded connections, re-apply thread sealant. Reduced flow can indicate a blockage. You inspect the valve for debris. You also check the pipeline for obstructions. If a valve is difficult to operate, you lubricate moving parts. You use a PVC-compatible lubricant. Always depressurize the system before you attempt any repairs.

Cost-Benefit Analysis and Long-Term Value of PVC Fittings Valves

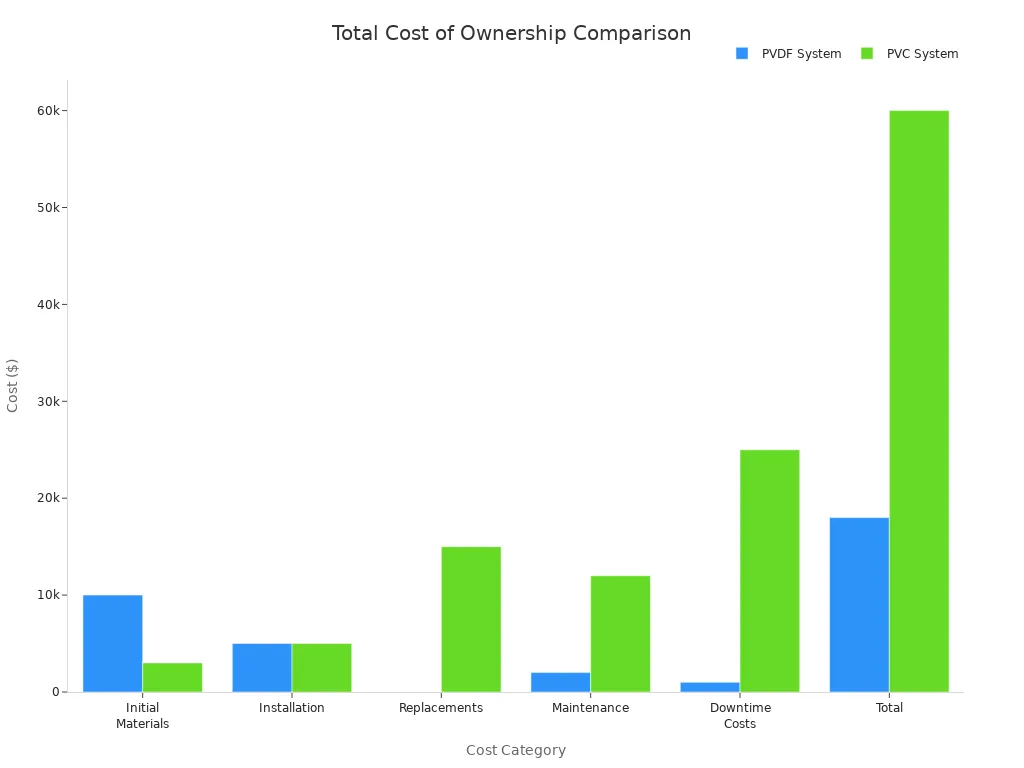

Balancing Initial Investment with Performance for PVC Fittings

You must carefully weigh the initial cost against the long-term performance of PVC fittings. Sometimes, a higher upfront investment leads to greater savings over time. For instance, while PVDF fittings initially cost more than conventional plastic alternatives like PVC, the total cost equation often favors PVDF in demanding applications. This happens because of an extended service life, eliminated failures, and reduced maintenance. These factors create substantial savings over the system’s lifetime. You choose the right material based on your specific application needs and expected lifespan.

Total Cost of Ownership for PN10 PVC Systems

You should consider the total cost of ownership (TCO) for your PN10 PVC systems. This includes material, installation, maintenance, and lifespan. PN10 PVC pipes are generally less expensive than metal alternatives like ductile iron, stainless steel, or copper. This applies to both initial material cost and overall lifecycle expenses. Their installation is faster due to simple solvent cement joining methods. This requires less labor and specialized tools. Combined with minimal maintenance needs and a long operational life, the total cost of ownership is significantly lower.

| Cost Factor | Water PN10 PVC Pipes | Metallic Pipes (Steel/Copper) |

|---|---|---|

| Material Cost | Low – economical thermoplastic | High – more expensive raw materials |

| Installation Cost | Low – lightweight, easy to cut and join | High – requires welding, threading, or specialized tools |

| Maintenance | Minimal – resistant to corrosion and scaling | Frequent – susceptible to rust, pitting, and mineral buildup |

| Lifespan | 50+ years with little degradation | 20–40 years, often shorter in corrosive environments |

| Total Lifecycle Cost | Significantly lower | Higher due to replacements and repairs |

You also benefit from:

- Lower material and installation costs due to lightweight design and simple joining methods.

- No need for anti-corrosion treatments, linings, or cathodic protection systems.

- Reduced maintenance and repair frequency thanks to long-term durability.

- Lifespans exceeding 50 years under proper conditions, minimizing replacement cycles.

Economic Advantages of High-Quality PVC Fittings Valves

You gain several economic advantages by investing in high-quality PVC fittings valves.

- Lower initial costs compared to materials like copper, steel, or concrete make PVC an attractive option for minimizing upfront expenses.

- Competitive market pricing comes from widespread availability of PVC resin and established production processes. This ensures affordability.

- An extended lifespan, often exceeding 50 years, prevents frequent replacements and repairs. This leads to long-term savings.

- Resistance to corrosion and chemical damage, unlike metal pipes, avoids costly repairs and replacements caused by degradation.

- Minimal maintenance requirements reduce upkeep costs. You eliminate the need for frequent inspections, repairs, or replacement parts.

- Ease of installation due to lightweight nature reduces labor costs and overall project expenses.

PVC water pipe can last 100 years or more. This contributes to long-term sustainability. Made of inert materials, PVC pipes are less prone to corrosion. This prevents breaks and water contamination. Research from Utah State University indicates that PVC pipe has the lowest overall break rate. This significantly reduces the total cost of ownership.

Future Trends and Innovations in PVC Fittings Valve Technology for 2026

Emerging Materials and Manufacturing Processes for PVC Fittings

You will see significant advancements in PVC fittings technology by 2026. Manufacturers are developing new PVC formulations. These enhance properties like flexibility, impact resistance, and temperature tolerance. Innovations also include biocompatible and environmentally friendly PVC. These advancements make PVC fittings suitable for a broader range of applications, even in harsh conditions. You will also find new additives like plasticizers and stabilizers. These improve PVC’s resistance to UV light, chemicals, and temperature fluctuations. Lead-free stabilizers are replacing harmful additives, improving safety for drinking water systems.

Manufacturing processes are also evolving. Extrusion technology has become more precise and efficient. This includes improved controls over temperature, pressure, and speed. The development of multilayer extrusion allows for pipes with enhanced performance. These offer improved impact resistance, better chemical resistance, and greater flexibility. You will also notice a shift towards more sustainable practices. This includes using bio-based materials and energy-efficient methods. Automation is increasing, with robotics and automated systems improving efficiency and consistency. You can expect more customized PVC resin products. Manufacturers will tailor properties like color, hardness, and chemical resistance to your specific needs.

Smart Valve Technologies and Their Impact on PVC Fittings

Smart valve technologies will transform PVC fittings systems. You will find embedded sensors in smart PVC pipes. These detect pressure changes, temperature fluctuations, and potential leaks. This provides real-time data for proactive maintenance. It also allows for quick issue resolution. This enhances the reliability and safety of your plumbing systems. Remote monitoring systems allow continuous observation of PVC pipe performance. Facility managers can identify and address problems before they escalate. This reduces downtime and extends the lifespan of your PVC pipes.

Smart technologies in uPVC pipe fittings provide monitoring and diagnostic capabilities. You can assess system performance, structural integrity, and potential issues in real-time. This leads to enhanced predictive maintenance and improved operational efficiency. IoT integration in uPVC pipe fittings enables remote monitoring, data analytics, and automated control. This optimizes system performance. It also provides actionable insights for proactive decision-making. Smart valve systems are integrating into uPVC octagonal ball valves. This enhances efficiency and reliability. Experts project that adding IoT to these valve systems will cut operational downtime by 40%.

Anticipated Changes in DIN/ASTM Standards for PN10 PVC Fittings

You should anticipate ongoing evolution in DIN and ASTM standards. These organizations regularly review and update their specifications. This ensures they reflect the latest material science and manufacturing capabilities. You can expect changes to address new environmental concerns. They will also incorporate advancements in testing methodologies. These updates will likely focus on enhancing product safety and performance. They will also aim to improve interoperability between different systems. Staying informed about these changes will help you select compliant and future-proof PVC fittings.

You must take a comprehensive approach when selecting PN10 DIN/ASTM compliant PVC fittings valves. This involves understanding specific pressure ratings, adhering to relevant DIN/ASTM standards, and carefully considering material compatibility. Proper installation techniques and diligent maintenance protocols are crucial for optimal system performance. By making informed choices, you assure the longevity and reliability of your PVC fittings valves for years to come.

FAQ

What does PN10 mean for PVC valves?

PN10 means the valve can handle 10 bar of pressure. This is about 145 PSI. You measure this at 20°C. This rating ensures your system operates safely.

Why are DIN and ASTM standards important for PVC fittings?

These standards ensure quality and compatibility. They provide guidelines for materials, dimensions, and testing. You can trust products meeting these standards. They guarantee reliable performance for your PVC fittings.

Which PVC material is best for hot water applications?

cPVC (chlorinated Polyvinyl Chloride) is best for hot water. It handles higher temperatures than uPVC. You should choose cPVC for warm or hot fluid applications. It maintains its strength at elevated temperatures.

What is the most reliable way to connect PVC fittings for PN10 systems?

Socket connections offer the most reliable bond. You use solvent cement to fuse the surfaces. This creates a strong, leak-proof joint. You must allow proper curing time for the cement.

How often should I inspect my PN10 PVC system?

You should visually inspect your PVC system every few months. Look for cracks or loose connections. Address any issues immediately. Regular checks prevent small problems from becoming major failures.

See Also

Selecting The Perfect Air Fryer Mat For Your Culinary Space

Best Air Fryer Alternatives Beyond BrandsMart: 2024′s Top Picks

Essential Accessories To Elevate Your Air Fryer Pan Experience

Five Essential Industrial Air Fryers For High-Volume Kitchens