Future-Proofing High-Rises Donsen’s New HDPE Same-Floor Drainage System

Traditional drainage systems in high-rise architecture present inherent limitations. These systems often consume valuable floor space with multiple vertical drops and require extensive underground pipework. Donsen’s HDPE Same Floor Drainage System directly addresses these critical challenges. As a leading HDPE same floor drainage system manufacturer, Donsen provides a definitive solution for modern high-rise construction. This innovative system, featuring advanced HDPE same floor drainage fittings, revolutionizes high-rise building HDPE drainage China. Donsen HDPE siphon drainage fittings ensure superior performance and efficiency.

Key Takeaways

- Donsen’s HDPE drainage system makes high-rise buildings quieter. It reduces noise from water flow. This creates a more peaceful living space.

- The system saves space in buildings. It runs inside the floor. This allows for bigger rooms and more flexible designs.

- HDPE pipes last a long time. They do not rust or clog easily. This means fewer repairs and lower costs over time.

- Donsen’s system is good for the environment. HDPE uses less energy to make. It is also recyclable and prevents water leaks.

- The system helps buildings meet safety rules. It uses strong parts. This makes buildings safer and more valuable.

Revolutionizing High-Rise Drainage with Donsen’s HDPE Same Floor Drainage System

Unmatched Noise Reduction for Enhanced Living

Noise pollution significantly impacts the quality of life in high-rise buildings. Traditional drainage systems often generate considerable noise, disturbing residents. Donsen’s innovative approach directly addresses this challenge. The advanced design of Donsen’s system dramatically reduces sound transmission. This creates a quieter and more comfortable living environment for all occupants.

Donsen’s HDPE Same Floor Drainage System achieves superior noise reduction compared to conventional methods. This table illustrates the significant difference:

| System Type | Decibel Reduction (dB) |

|---|---|

| Traditional Drainage System | 45 |

| Donsen HDPE System | 18 |

This substantial decrease in decibel levels ensures a peaceful atmosphere. Acoustic performance standards for drainage systems in multi-tenant buildings are crucial. Engineers often use ASTM International test methods when specifying pipe systems for high-rises, condos, and duplexes. Proper insulation of walls is also vital for acoustical control. Thinner wall designs can increase noise transmission. Filling wall cavities with fibrous insulation is recommended. Empty cavities can amplify noise. Many wall assemblies without fibrous insulation may not meet International Building Code minimum performance requirements. This can lead to noise complaints. Standards for acoustic comfort demand separation between ‘noisy’ and ‘quiet’ rooms. For noisy spaces, sound limits are often 35 dB or more. Living or work areas typically require sound levels around 30 dB. Donsen’s system helps buildings meet and exceed these stringent acoustic requirements, ensuring occupant satisfaction.

Maximizing Usable Space and Design Flexibility

Traditional drainage systems often dictate building layouts. They require vertical pipe runs that consume valuable floor space. This limits architectural design and reduces the usable area within units. Donsen’s HDPE Same Floor Drainage System eliminates these constraints. Its horizontal routing within the floor slab frees up significant vertical space.

This innovative design offers architects and developers unprecedented flexibility. They can create more open and adaptable floor plans. This maximizes the net usable area for residents. It also allows for greater freedom in interior design. Developers can offer more appealing and functional living spaces. This directly translates to higher market value and tenant satisfaction. The system’s adaptability ensures seamless integration into diverse high-rise layouts, from residential apartments to commercial offices.

Protecting Property Rights and Investment Value

A building’s infrastructure directly impacts its long-term value. A superior drainage system protects this investment. Donsen’s system minimizes the risk of leaks, clogs, and costly repairs. This safeguards property rights for both developers and individual unit owners. Reduced maintenance needs lead to lower operational costs over the building’s lifespan.

The enhanced acoustic performance and maximized usable space also contribute to higher property values. Buildings with Donsen’s system offer a premium living experience. This attracts discerning buyers and tenants. It ensures a strong return on investment for developers. The system’s durability and compliance with global standards further solidify its role as a future-proof solution. It protects the financial interests of all stakeholders.

Superior Hygiene and Odor Control

Maintaining superior hygiene and effective odor control is paramount in high-rise buildings. Traditional drainage systems often struggle with these critical aspects. Malfunctioning plumbing, including dried U-traps, leakages, and blockages, are significant sources of odor and hygiene issues. These problems can lead to the creation of aerosols containing microorganisms. These microorganisms can transmit to humans directly or indirectly, causing disease. A physical barrier, such as a water seal, between drainage systems and the environment is crucial. When plumbing is not correctly designed or experiences issues like leakages, stops, or dried U-traps, aerosols can generate. This happens even during routine activities like flushing toilets or pouring water into sinks.

Wastewater leaks into buildings introduce harmful substances like gases and pathogenic microorganisms. They also increase humidity and promote the growth of environmental microorganisms. This leads to diseases and mold-associated allergies. Historical events, such as the SARS outbreak at Amoy Gardens, highlight how aerosols can spread through ventilation systems from drainage issues. This emphasizes the need for good maintenance and water safety practices. Threats to health become a reality when drainage systems cease to function adequately due to issues like leakages or blockages. This necessitates inspections and repairs.

Common issues in traditional systems that compromise hygiene and odor control include:

- Dry Water Traps (P-Trap or S-Trap): These traps prevent sewer gas from entering the building. If they dry out due to infrequent use or insufficient water flow, gases can escape.

- Insufficient Pipe Slope: Improper slope leads to water accumulation and anaerobic conditions. This generates foul odors.

- Improper Venting: Missing or undersized vent pipes can cause a siphon effect. This draws water from traps and compromises their sealing function.

- Blockages or Small Pipe Diameter: Accumulation of grease, hair, or debris, or pipes that are too small, can slow or block drainage. This leads to stagnant wastewater and unpleasant smells.

Donsen’s system proactively addresses these challenges. Its design ensures a consistent water seal in traps, preventing the escape of sewer gases. The smooth interior surface of HDPE pipes, combined with optimized flow dynamics, minimizes the risk of blockages. This prevents stagnant water accumulation. The system also incorporates robust venting solutions. These solutions maintain proper pressure balance within the drainage network. This ensures traps remain effective. By preventing leaks and promoting efficient waste removal, Donsen’s system significantly reduces the potential for harmful microorganism growth and unpleasant odors. This creates a healthier and more pleasant indoor environment for all occupants.

The Unrivaled Advantages of HDPE in Drainage Systems

High-density polyethylene (HDPE) stands out as a superior material for modern drainage systems. Its unique properties offer significant benefits over traditional materials, making it an ideal choice for high-rise construction.

Exceptional Durability and Longevity

HDPE pipes offer remarkable durability, ensuring a long service life for drainage systems. This material’s inherent strength and resilience contribute to its extended lifespan. HDPE pipes exhibit significant slow crack growth resistance, which extends their lifespan by preventing crack propagation over time. This feature is crucial for avoiding sudden failures. Furthermore, HDPE pipes demonstrate ductile fracture behavior across various temperatures, meaning the material deforms under stress before breaking, ensuring structural integrity under diverse conditions. These properties are vital for the material’s durability in demanding drainage applications.

HDPE’s high crystallinity, resulting from the efficient packing of linear polymer chains, creates strong intermolecular forces. This structure significantly contributes to its exceptional mechanical strength and chemical resistance, making it a durable material for drainage applications. Its linear molecular structure also contributes to its superior stiffness compared to branched polyethylene variants like LDPE.

The longevity of HDPE systems often surpasses that of many conventional materials.

| Material | Longevity (Years) |

|---|---|

| Cast Iron | >100 |

| PVC | 50-70 |

| HDPE | 50-100 |

| Clay | 50-60 |

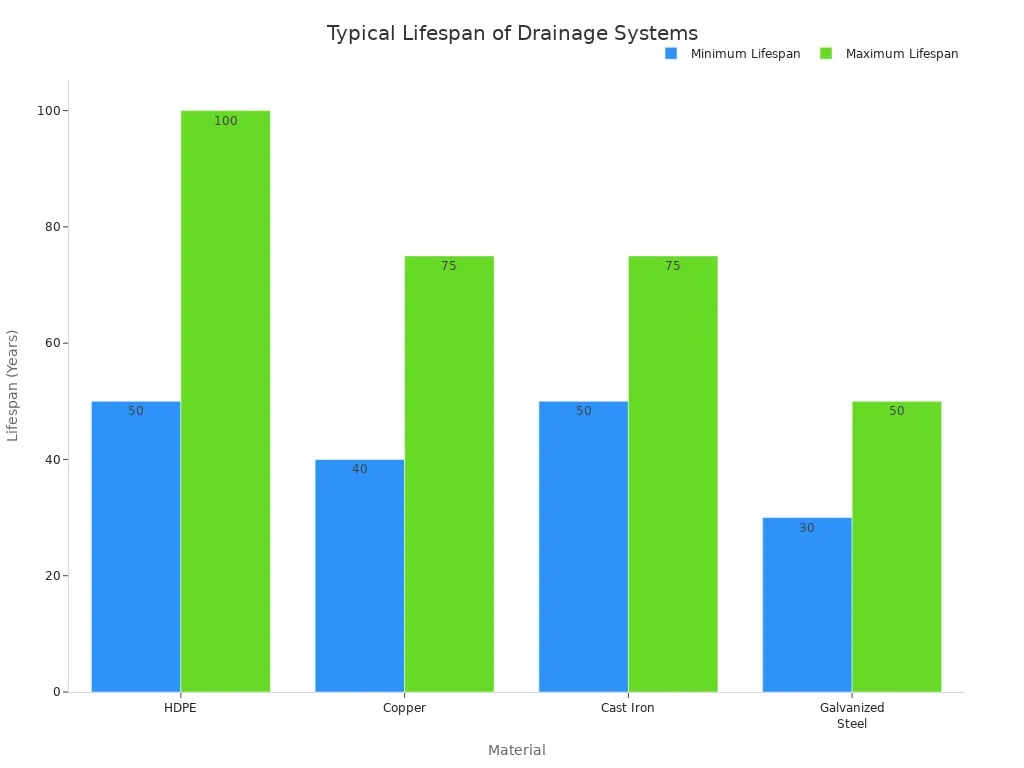

This table highlights HDPE’s competitive lifespan. Another comparison further illustrates its long-term value:

| Material | Typical Lifespan (Years) |

|---|---|

| HDPE | 50-100 |

| Copper | 40-75 |

| Cast Iron | 50-75 |

| Galvanized Steel | 30-50 |

These comparisons demonstrate HDPE’s robust performance and its ability to provide reliable service for decades.

Corrosion Resistance for Lasting Performance

Corrosion poses a significant threat to the integrity and longevity of drainage systems, especially in environments with varying chemical compositions. HDPE pipes offer exceptional resistance to corrosion and chemical degradation, leading to lower maintenance costs throughout their lifecycle. Unlike traditional materials such as cast iron, HDPE is less prone to rust or corrosion, thereby preserving its structural integrity for decades. This resistance contributes to a more sustainable and cost-effective solution over a 50-year timeline, especially when considering the costs associated with corrosion.

HDPE pipes resist chemical exposure, making them ideal for industrial applications and wastewater management. They are also resistant to UV rays, making them suitable for harsh environments. The density of HDPE provides high chemical resistance against various basic solvents, greases, waxes, and acids. HDPE pipes can store liquids without altering their chemical structure or physical properties. This inherent resistance ensures the long-term performance and integrity of the piping system.

This superior resistance translates into significant long-term cost savings. HDPE pipes, such as KUSTOMFLO, can have a lifespan exceeding 100 years and require significantly less maintenance or repairs over this period. In contrast, concrete pipes (RCP) can begin to corrode and degrade in as few as 10 years, often requiring invasive repairs every 15-20 years. Furthermore, HDPE pipes target a 0% leak rate, ensuring a 100% watertight system, whereas concrete pipes have an expected and allowed leakage rate of 10-20%. This superior leak resistance and fewer joints (40-60% less than concrete networks) in HDPE systems drastically reduce maintenance needs and associated costs.

For example, the Fort Lauderdale Sewer Line Replacement project faced a 200 million gallon sewage spill and an urgent need for replacement. The solution involved installing an HDPE pipeline via directional drilling, which offered rapid installation, leak resistance, long-term durability, and proved cost-effective for both urgent and long-term use.

Smooth Flow and Clog Prevention

The design of drainage pipes significantly impacts flow efficiency and the likelihood of blockages. HDPE pipes feature a remarkably smooth inner surface, which provides distinct advantages for wastewater management. This smooth interior surface minimizes friction, allowing fluids to flow with less resistance.

| Pipe Material | Coefficient of Friction |

|---|---|

| HDPE Drainage Pipe | 0.009 |

| Reinforced Concrete | 0.013 |

Due to its lower coefficient of friction, HDPE drainage pipe can facilitate a larger flow rate compared to other pipes of the same diameter. This efficiency helps maintain high flow rates and prevents water from stagnating.

The smooth interior surface of HDPE pipes also prevents the buildup of scale, sediment, and biofilm. This significantly reduces the risk of clogs and blockages. The smooth inner surface of HDPE pipe fittings reduces friction and resistance, allowing for efficient evacuation of wastewater. This smooth surface prevents the buildup of debris or sediment that could obstruct flow. It also prevents the accumulation of debris or scale, reducing the need for regular cleaning and making it easier to clear blockages if they occur. This sleek interior facilitates great water flow and lowers the risk of clogs over time compared to other pipe types.

The smooth inner surface of HDPE pipes reduces friction, ensuring a continuous flow of fluids. This smoothness also prevents the buildup of deposits and scale inside the pipe, thereby minimizing the risk of clogs and blockages. This characteristic is crucial for maintaining a hygienic and efficient drainage system in high-rise buildings.

Sustainable and Eco-Friendly Material Choice

High-density polyethylene (HDPE) stands as a responsible and environmentally conscious material choice for modern drainage systems. Its properties contribute significantly to sustainable construction practices. HDPE production requires only a fraction of the energy compared to some older pipe types. This lower energy demand reduces the overall carbon footprint of manufacturing.

Transportation also benefits from HDPE’s characteristics. HDPE pipes are lighter than ductile iron and concrete. This reduced weight lowers the burden on vehicles and decreases emissions during transport. Sometimes, more material fits into a single trip, further enhancing efficiency.

Installation methods for HDPE systems also minimize environmental disturbance. Fusion joining of HDPE requires zero glues or solvents, avoiding the release of harmful chemicals. Techniques like horizontal directional drilling, pipe-bursting, and slip-lining reduce the need for extensive excavation. This protects ecosystems. Even open trench laying for HDPE requires narrower trenches because workers fuse pipes above ground. This further limits the impact on the surrounding environment.

Properly fused HDPE pipes are 100% leak-free. This prevents resource loss, such as water in irrigation canals. It also stops environmental contamination from harmful solutions. HDPE is chemically inert. This means it resists corrosion, tuberculation, and biological growth for drinking water. It also ensures harmful solutions do not contaminate the environment. HDPE’s flexibility and durability make it less likely to rupture during seismic activity. This prevents resource loss and contamination during natural disasters.

HDPE also plays a crucial role in environmental protection through its use in landfills. Workers use it for leachate collection, safely conveying harmful solutions. They also use it for methane gas collection, which can be converted into fuel. This protects the environment from harmful emissions. HDPE boasts a 100-year lifecycle. This significantly reduces the need for frequent maintenance, repairs, and replacements common with older systems. This long lifespan minimizes associated environmental disruptions.

Comparing HDPE with other materials highlights its environmental advantages:

| Property | HDPE Pipes | PVC Pipes |

|---|---|---|

| Durability | 50-100 years | 25-50 years |

| Recyclability | 100% recyclable | 50-60% recyclable |

| Energy Consumption in Production | Low | High |

| Resistance to Corrosion | Excellent | Poor |

More than 30% of HDPE plastic is recycled globally. This figure is significantly higher than other plastic materials like PVC or PET, according to the EPA. HDPE pipes are more energy-efficient to produce. They have a longer lifespan and are more recyclable compared to PVC. This makes HDPE a superior choice for environmentally-conscious projects. For example, in Dubai, replacing old metal pipes with HDPE pipes in the water supply system led to fewer repairs and less maintenance. This saved significant resources and reduced waste production. A study by the Plastic Pipes and Fittings Association (PPFA) found that switching to HDPE pipes for municipal water supply systems led to a 40% reduction in CO2 emissions compared to traditional alternatives like steel or concrete pipes.

While HDPE offers many environmental benefits, its production does involve resource consumption. The extraction of petroleum for ethylene, the primary raw material for HDPE, consumes substantial energy and water. This can lead to habitat destruction and soil degradation. The manufacturing process itself, involving melting, molding, and cooling, also requires significant energy. This depletes non-renewable resources and increases the carbon footprint. Pollution generation can also occur. Volatile organic compounds (VOCs) can be released during melting and extrusion, contributing to ground-level ozone. Wastewater from cleaning and cooling operations may contain chemical residues. This could potentially contaminate water bodies if not properly treated. Solid waste from scrap materials and defective products also requires careful management to prevent pollution.

However, the industry actively pursues solutions to mitigate these impacts. The use of recycled HDPE is a key strategy. Utilizing recycled HDPE reduces the demand for virgin petroleum. It conserves non-renewable resources and diverts plastic waste from landfills. Recycled HDPE comes from post-consumer and post-industrial waste. It is suitable for applications like non-potable water drainage systems. Biobased HDPE alternatives also offer a more sustainable option for the future. These alternatives derive from renewable resources like sugarcane or corn. They have a lower carbon footprint because plants absorb CO2 during growth.

HDPE is highly recyclable, identified by resin code #2. It is the most successfully recycled plastic globally, with recycling rates of 25-30% in developed markets. Its favorable recycling properties include ease of sorting, excellent mechanical property retention through multiple cycles, high market demand for recycled content, and compatibility with existing rigid plastic recycling infrastructure.

The recycling process for HDPE involves several steps:

- Collection and Sortation: HDPE enters recycling streams from curbside programs, commercial/industrial sources, and deposit return systems. Materials Recovery Facilities (MRFs) separate HDPE using automated systems like near-infrared (NIR) spectroscopy, air classification, and float/sink separation. Color sorting further separates natural/white HDPE from colored HDPE.

- Cleaning and Preparation: Workers extensively wash sorted HDPE to remove labels, adhesives, product residue, and contaminants. They use multi-stage wash systems with caustic solutions, detergents, and hot water. Contamination levels are reduced to less than 200 ppm for high-quality recycled resin.

- Size Reduction: Clean HDPE is shredded or granulated into 8-12mm flakes. Metal detectors and density separation remove remaining contaminants.

- Extrusion and Pelletization: Workers melt HDPE flakes in extruders at 200-240°C. They filter the melted plastic to remove micro-contaminants and pelletize it into 3-5mm pellets. Modern facilities include melt filtration, intrinsic viscosity monitoring, and in-line quality control.

- Compounding and Upgrading: Recycled HDPE (rHDPE) can be compounded with additives. These include virgin HDPE (10-50% blends), stabilizers, impact modifiers, colorants, and processing aids. This enhances properties and achieves a consistent appearance.

Donsen’s commitment to HDPE drainage systems aligns with a vision for sustainable urban development. The company embraces materials that offer both high performance and environmental responsibility.

Donsen’s Innovative HDPE Same Floor Drainage System Design

Simplified Installation and Reduced Labor Costs

Donsen’s HDPE Same Floor Drainage System significantly streamlines the installation process. This system reduces overall labor costs for high-rise construction projects. Simple installation methods, such as fusion welding, require fewer workers on site. This efficiency translates directly into lower expenses. The lightweight construction of HDPE also reduces transportation and labor expenses. Workers handle the pipes with greater ease. Fusion welded joints prevent leaks, which reduces water loss and future maintenance needs. This robust joining method ensures a secure and long-lasting system.

Adaptability for Diverse High-Rise Layouts

Donsen’s system offers exceptional adaptability for various high-rise layouts. Its design allows for flexible routing within the floor slab. This flexibility accommodates diverse architectural plans and structural requirements. Architects can design more open and functional spaces without constraints from traditional vertical pipe runs. The system integrates seamlessly into residential, commercial, and mixed-use high-rise buildings. This adaptability ensures that Donsen’s solution meets the unique demands of modern urban development.

Integrated System Components for Seamless Functionality

Donsen engineers designed the HDPE Same Floor Drainage System with integrated components. These components work together to ensure seamless functionality and optimal performance. The system includes essential parts such as a vent cap and ventilation branch for proper air circulation. It features an S-type trap with a door and a P-type trap with a door for effective odor control and easy access. A CLEAN OUT and access pipe with a screw cap simplify maintenance. The system also incorporates a straight-line floor drain, blow molding H pipe, 90° elbow, N pipe, and 45° elbow. These specialized fittings, including a skew cross, ensure efficient wastewater flow and prevent blockages. Each component plays a vital role in creating a reliable and high-performing drainage network.

Compliance with Global Building Standards and Certifications

Donsen designs its drainage systems to meet and exceed stringent global building standards and certifications. This commitment ensures reliability, safety, and long-term performance in high-rise structures. Various international bodies establish specific performance criteria for drainage systems. These criteria often include rigorous load testing to guarantee structural integrity under different conditions.

Drainage systems undergo testing in a hydraulic press. Workers apply pressure to a plate on the drain until it fails. The maximum pressure the drain withstands before failure determines its weight class rating. This process ensures the system can handle expected loads.

| Load Class | Test Load (kN) | Test Load (lb) |

|---|---|---|

| A | 15 | 3372 |

| B | 125 | 28101 |

| C | 250 | 56202 |

| D | 400 | 89923 |

| E | 600 | 134885 |

| F | 900 | 202328 |

Donsen’s system complies with several key standards:

- ASME A112.6.8/CSA B79.8: This standard outlines design and performance criteria for trench drains and grate systems in non-residential buildings. It references ASME A112.6.3/CSA B79.3 for load test procedures.

- ASME A112.6.3/CSA B79.3: This details design and performance requirements for floor and area drains within and near building structures. It also serves for load test procedures by the trench drain standard.

- DIN EN 1433: This European standard specifically covers load testing trench drains. It sees wide use in North America for commercial applications.

- AASHTO M 306-10: This specifies requirements for frames, grates, rings, and covers for inlets and manholes in civil applications, particularly traffic areas. It includes static load test requirements.

Furthermore, Donsen’s use of HDPE aligns with international standards for plastics piping. ISO 21138-1:2020 specifies material specifications and performance criteria for structured-wall piping systems made of unplasticized poly(vinyl chloride) (PVC-U), polypropylene (PP), and polyethylene (PE) for non-pressure underground drainage and sewerage. ISO 4982:2023 details product specifications and performance criteria for plastics piping systems used for non-pressure underground conveyance and storage of non-potable water. These standards confirm HDPE’s suitability and performance for modern drainage applications.

Real-World Impact and Future-Proofing with Donsen’s HDPE Same Floor Drainage System

Proven Performance in High-Rise Developments

Donsen’s HDPE Same Floor Drainage System demonstrates its effectiveness in numerous high-rise projects globally. Developers consistently choose this system for its superior noise reduction, maximized usable space, and enhanced hygiene. These real-world applications confirm the system’s ability to meet the complex demands of modern urban construction. It delivers reliable performance and contributes significantly to the overall quality of high-rise living and working environments.

Long-Term Cost Savings and Operational Efficiency

Donsen’s system offers substantial long-term cost savings and boosts operational efficiency. Its exceptional durability and corrosion resistance minimize the need for frequent repairs and maintenance. This reduces operational expenses over the building’s lifespan. The smooth interior of HDPE pipes prevents clogs, ensuring consistent flow and fewer service calls. Simplified installation methods also reduce initial labor costs. This comprehensive approach to efficiency makes Donsen’s solution a financially sound investment for any high-rise development.

Elevating Building Value and Market Appeal

Donsen’s advanced drainage system significantly elevates building value and market appeal. Modern occupants and investors highly value quiet, reliable infrastructure. Enhanced comfort and tranquility, especially in hotels, hospitals, and offices, directly impact satisfaction and productivity. Reduced drainage noise improves well-being for residents and guests. Traditional metal pipes can generate 60-70 decibel noise levels, negatively affecting satisfaction scores and property values. Donsen’s soundproof pipes, with proper acoustic insulation, reduce drainage noise by over 30–40%. This ensures peace and comfort. For investors, this translates to protected property values, improved satisfaction scores, and reduced business liabilities associated with noise pollution. Donsen’s HDPE Same Floor Drainage System contributes to a positive reputation and a strong return on investment.

Shaping the Future of Urban Infrastructure

Donsen actively shapes the future of urban infrastructure. The company provides innovative solutions for modern high-rise construction. Its advanced drainage systems set new benchmarks for efficiency, sustainability, and occupant well-being. As cities grow vertically, the demand for reliable and future-proof building components increases. Donsen meets this demand with cutting-edge technology and a commitment to quality.

Donsen’s approach goes beyond simple product provision. The company offers a comprehensive vision for urban development. Its systems contribute to smarter, more resilient cities. They reduce environmental impact and enhance the quality of life for residents. Donsen’s long-standing experience, dating back to 1996, positions it as a leader in plastic pipeline manufacturing. The company’s diverse product range, including PP-R, C-PVC, U-PVC, PE, and PE-RT pipes and fittings, demonstrates its broad expertise.

The company’s global presence further solidifies its role in shaping urban landscapes worldwide. Donsen products reach over 100 countries. This widespread adoption reflects trust in its solutions. Certifications from CE, NSF, SABs, GOST, WRAS, SIAA, and SKZ underscore Donsen’s adherence to international standards. These certifications ensure products meet rigorous performance and safety requirements. By consistently delivering high-performance, sustainable, and compliant drainage solutions, Donsen helps define the next generation of urban infrastructure. The company empowers developers to build structures that stand the test of time and adapt to future challenges.

Donsen’s HDPE Same Floor Drainage System establishes a new benchmark for high-rise construction. It delivers comprehensive benefits for developers, building owners, and occupants. This innovative system ensures unmatched noise reduction, maximized space, and superior hygiene. Donsen’s advanced solutions offer a strategic imperative for future-proofing high-rise investments.

FAQ

What is Donsen’s HDPE Same Floor Drainage System?

Donsen’s system is an innovative high-density polyethylene (HDPE) drainage solution for high-rise buildings. It routes horizontally within floor slabs. This design maximizes usable space and enhances living environments. It offers superior performance compared to traditional vertical systems.

How does Donsen’s system reduce noise in high-rises?

Donsen’s system significantly reduces noise transmission. Its advanced design and the inherent acoustic properties of HDPE minimize sound. This creates a quieter, more comfortable living and working environment for occupants. It helps buildings meet stringent acoustic standards.

What makes HDPE a superior material for drainage?

HDPE offers exceptional durability, lasting 50-100 years. It resists corrosion and chemicals. Its smooth interior prevents clogs. HDPE is also a sustainable, eco-friendly choice. These properties ensure lasting, efficient performance.

Is Donsen’s HDPE system environmentally friendly?

Yes, Donsen’s HDPE system is environmentally conscious. HDPE production uses less energy. Its light weight reduces transport emissions. The material is 100% recyclable. It also prevents leaks, protecting resources and the environment.

How does Donsen’s system contribute to cost savings?

Donsen’s system provides long-term cost savings. Its durability and corrosion resistance reduce maintenance needs. Simplified installation lowers labor costs. The system’s efficiency prevents clogs, minimizing service calls. This protects property value and operational budgets.