Evaluating PPR and CPVC Pipes for Hot Water Efficiency

When it comes to hot water efficiency, you might find yourself weighing PPR vs CPVC for hot water applications. Each material has unique properties that can significantly impact your plumbing system’s performance. Choosing the right one is crucial, as higher temperatures can affect PVC’s durability, leading to potential issues down the line. For reliable hot water delivery, consider how these materials perform over time, especially in terms of CPVC chemical resistance piping. If you’re looking for quality solutions, a trusted PPR pipe fitting supplier can provide the necessary components to ensure your system operates efficiently.

Key Takeaways

- PPR pipes excel in hot water applications due to their high temperature resistance, lasting over 50 years with low maintenance needs.

- CPVC pipes are more affordable initially but have a shorter lifespan of 20-30 years and require more frequent maintenance due to potential joint failures.

- Choosing the right pipe depends on your project needs: PPR offers durability and efficiency, while CPVC provides flexibility and lower upfront costs.

Physical Properties of PPR vs CPVC

When you evaluate PPR vs CPVC for hot water applications, understanding their physical properties is essential. Both materials have unique characteristics that can influence their performance in your plumbing system.

Density and Tensile Strength

- Density: PPR pipes typically have a lower density compared to CPVC, making them lighter and easier to handle during installation.

- Tensile Strength: CPVC pipes boast a higher tensile strength than both PVC and polypropylene pipes. This means they can withstand greater stress without breaking, which is crucial in high-pressure hot water systems.

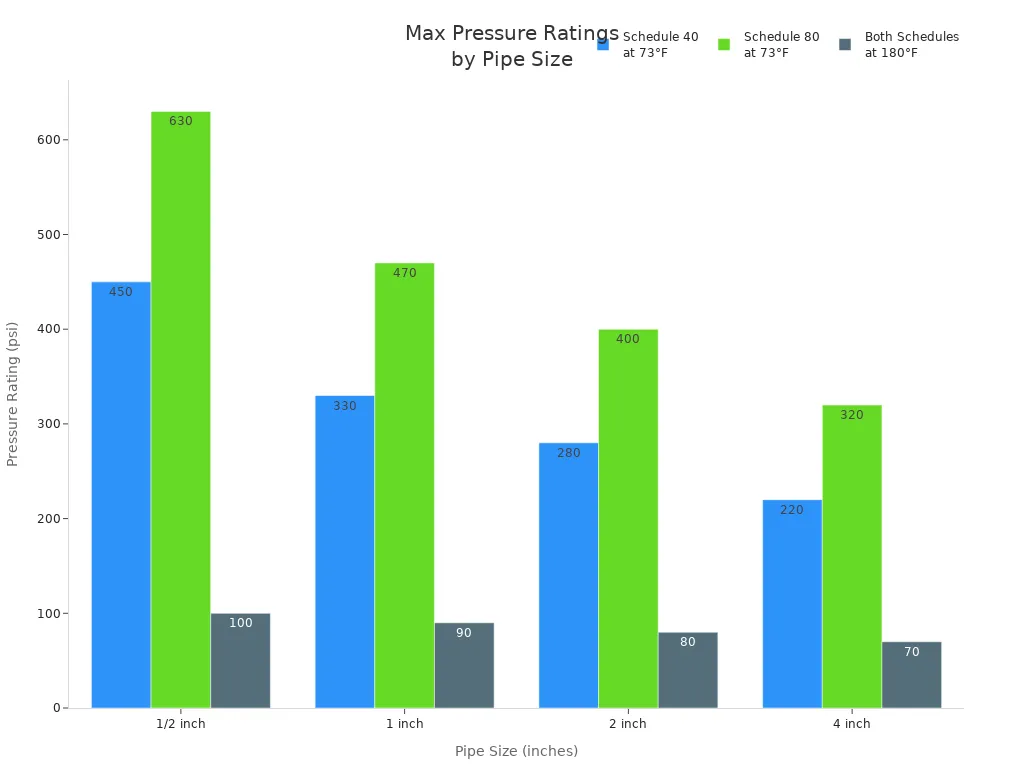

Pressure Ratings

Pressure ratings are vital when considering the suitability of pipes for hot water. Here’s a quick comparison of the maximum pressure ratings for PPR and CPVC pipes at standard operating temperatures:

| Pipe Size (inches) | Schedule 40 (73°F) | Schedule 80 (73°F) | Pressure at 180°F (Both) |

|---|---|---|---|

| 1/2 | 450 psi | 630 psi | 100 psi |

| 1 | 330 psi | 470 psi | 90 psi |

| 2 | 280 psi | 400 psi | 80 psi |

| 4 | 220 psi | 320 psi | 70 psi |

Impact Resistance

Impact resistance is another critical factor. PPR fittings can endure physical stresses without cracking or deforming, confirming their reliability in various operating conditions. However, keep in mind that:

- PPR pipes are generally lower in cost but may be more susceptible to mechanical impacts.

- They can crack under pressure or during installation, leading to potential leaks or bursts.

In contrast, CPVC pipes offer significant advantages, including better resistance to higher temperatures and a more secure installation process. This contributes to their overall durability in hot water systems.

Thermal Expansion

Thermal expansion can affect how pipes perform under heat. Here’s a comparison of the expansion coefficients for PPR and CPVC:

| Pipe Type | Continuous Temperature (°C) | Peak Temperature (°C) | Pressure Capacity at 60°C (PSI) |

|---|---|---|---|

| PPR | 70 | 95 | Maintains better pressure ratings |

| CPVC | 60 | 82 | Loses pressure capacity faster |

PPR can operate continuously at 70°C, while CPVC is rated for 60°C. PPR has a peak tolerance of 95°C compared to CPVC’s 82°C. This makes PPR a more reliable choice for hot water applications, especially since it uses heat fusion welding to create seamless connections. On the other hand, CPVC relies on solvent cement for joints, which can weaken over time, particularly under temperature fluctuations.

Temperature Resistance of PPR and CPVC

When it comes to hot water systems, temperature resistance is a key factor in choosing between PPR and CPVC pipes. You want materials that can handle high temperatures without compromising performance. Let’s break down how each type of pipe performs under heat.

Maximum Operating Temperatures

Both PPR and CPVC pipes have specific temperature ratings that dictate their suitability for hot water applications:

- PPR Pipes: These pipes can handle continuous operating temperatures up to 95°C (203°F). This high threshold makes them ideal for hot water systems.

- CPVC Pipes: On the other hand, CPVC pipes have a maximum continuous service temperature of 82°C (180°F). While this is sufficient for many applications, it falls short compared to PPR.

Performance Under Heat

Understanding how these materials behave at elevated temperatures is crucial. Here’s what you should know:

- PPR Pipes:

- They maintain their mechanical properties even at high temperatures. Their polypropylene random copolymer structure allows them to perform well under stress.

- PPR pipes have low thermal conductivity, which helps reduce surface temperature extremes. This means they can keep hot water hot without losing efficiency.

- CPVC Pipes:

- CPVC pipes can experience thermal aging, which leads to a degradation of their mechanical properties when exposed to temperatures between 80-90°C.

- High temperatures can cause cleavage of carbon-chlorine bonds in CPVC, resulting in free radicals that weaken the material over time. This can lead to a loss of tensile strength, making them less reliable in the long run.

Thermal Cycling and Stability

Another important aspect is how these pipes handle thermal cycling—repeated heating and cooling.

- PPR Pipes:

- They exhibit viscoelastic properties, allowing them to withstand thermal cycling without permanent deformation. This prevents micro-cracking, which can lead to leaks.

- Their high crystallinity provides stability during thermal expansion, minimizing heat loss and ensuring efficient hot water delivery.

- CPVC Pipes:

- While they can handle hot water, CPVC pipes may not perform as well under thermal cycling. Over time, they can lose strength and become more susceptible to damage.

Installation Methods for PPR and CPVC

When it comes to installing PPR and CPVC pipes, you’ll notice some key differences that can affect your project. Understanding these methods helps you choose the right one for your needs.

Joining Techniques

The joining methods for these pipes vary significantly:

| Pipe Type | Joining Method | Description |

|---|---|---|

| CPVC | Solvent Cement | Creates a chemical fusion, allowing for fast installation and permanent joints. |

| PPR | Heat Fusion | Provides leak-proof performance, high temperature and pressure resistance, and a long lifespan (50+ years). |

PPR pipes require specialized heat fusion equipment. This method creates strong, leak-proof joints that can withstand high temperatures. On the other hand, CPVC pipes use solvent cement, which is simpler but results in weaker chemical bonds.

Installation Time

You might also wonder how installation times compare. Here’s a quick look:

| Installation Factor | PPR System | CPVC System |

|---|---|---|

| Typical Joint Time | 20-45 seconds | 30-60 seconds plus curing |

During a large apartment project, our team found that PPR installation was quicker overall. While it requires specialized equipment, it allows for prefabrication, speeding up on-site assembly. CPVC, however, offers flexibility for complex routing and last-minute changes.

Cost Considerations

Cost is another factor to keep in mind. Here’s a comparison of installation costs:

| Cost Factor | PPR System | CPVC System |

|---|---|---|

| Material Cost (Average) | 20-30% higher | Lower initial cost |

| Installation Labor Cost | 15-25% lower | Higher due to slower joining |

| Expected Lifespan | 50+ years | 20-30 years |

| Maintenance Frequency | Very low | Moderate |

| Repair Probability | Low (joints don’t leak) | Medium (potential joint failures) |

While PPR may have a higher material cost, its lower labor costs and longer lifespan can make it a more economical choice in the long run.

Chemical Resistance of PPR vs CPVC

When choosing between PPR and CPVC for your hot water system, chemical resistance plays a crucial role. You want pipes that can withstand the harsh conditions of hot water and the chemicals that come with it. Let’s break down how each material performs.

Resistance to Common Chemicals

Both PPR and CPVC have different levels of resistance to various chemicals. Here’s a quick look at how they stack up:

| Chemical Type | Effect on PPR Pipes |

|---|---|

| Organic Solvents | PPR shows good resistance. Hydrocarbons like gasoline and diesel have little effect. However, strong polar solvents may cause swelling at high temperatures. |

| Oxidizing Agents | PPR has moderate resistance. Mild oxidizing agents like hydrogen peroxide are tolerated, but strong agents like nitric acid can cause oxidation. |

| Temperature Impact | Higher temperatures can increase susceptibility to chemical attack. Resistance to solvents may decrease. |

| Chemical Concentration | Higher concentrations can accelerate degradation. Careful selection of materials is necessary. |

| Duration of Exposure | Prolonged exposure can lead to gradual degradation. Regular inspection is essential. |

| Testing Methods | Immersion and accelerated aging tests help evaluate chemical resistance and predict long-term performance. |

Chlorine and Disinfectants

When it comes to chlorine and other disinfectants, CPVC has the upper hand. It doesn’t rely on sacrificial antioxidants for protection against chlorinated water, which contributes to its durability and longer service life. Here are some key points:

- CPVC pipes have inherent resistance to chlorine and disinfectants, making them suitable for long-term exposure in hot water systems.

- PPR pipes, on the other hand, are susceptible to degradation from hypochlorous acid. This can lead to oxidation stress cracking and erosion of the pipe wall.

Long-term Performance of PPR and CPVC

When you think about the long-term performance of PPR vs CPVC for hot water systems, several factors come into play. Both materials have their strengths, but they differ significantly in lifespan and maintenance needs.

- Lifespan:

- PPR pipes can last 50+ years, making them a reliable choice for hot water applications.

- In contrast, CPVC pipes typically last around 20-30 years. This means PPR pipes can nearly double the lifespan of CPVC pipes.

- Maintenance Requirements:

- Over a 20-year period, PPR pipes show a 70% reduction in maintenance calls. Their heat fusion joints are less prone to leaks, which means you spend less time worrying about repairs.

- CPVC pipes, however, require more frequent maintenance due to their solvent-cement joints, which can fail over time.

Here’s a quick comparison of maintenance needs:

| Pipe Type | Lifespan | Maintenance Reduction | Joint Type | Susceptibility to Leaks |

|---|---|---|---|---|

| PPR | 50+ years | 70% reduction in calls | Heat fusion | Low |

| CPVC | ~25 years | Higher maintenance | Solvent-cement | Higher |

- Common Failure Modes:

- Thermal Expansion

- Incompatibility of Plumbing Pipes

- Cracks Reforming in Plumbing Pipes

- Failed Application of Solvent Cement

- Untrained Plumbers

- Incorrect Maintenance

- Plumbing System Design Issues

Understanding these factors helps you make an informed decision when choosing between PPR and CPVC for your hot water system. With PPR’s longer lifespan and lower maintenance needs, it often proves to be the more efficient choice in the long run.

In summary, both PPR and CPVC pipes have their strengths for hot water applications. Here’s a quick comparison:

| Feature | CPVC | PPR |

|---|---|---|

| Maximum Temperature Rating | Up to 93°C (200°F) | 70°C (158°F) |

| Initial Cost | Higher | 10-15% lower |

| Service Life | 25-30 years | 50+ years |

If you need durability and lower maintenance, PPR is your best bet. For projects requiring flexibility and lower initial costs, CPVC might fit the bill. Choose wisely based on your specific needs!

FAQ

What are the main benefits of using PPR pipes for hot water systems?

PPR pipes offer high temperature resistance, durability, and low maintenance, making them ideal for efficient hot water delivery.

How long do CPVC pipes typically last?

CPVC pipes generally last around 20 to 30 years, depending on usage and environmental conditions.

Can I use PPR pipes for cold water applications?

Absolutely! PPR pipes work well for both hot and cold water systems, providing versatility in plumbing projects.