Are all PVC valves the same size?

Manufacturers do not produce all PVC valves in the same size. They design these essential components in a wide range of dimensions. This diverse sizing matches varying pipe diameters. It also accommodates numerous application requirements across different systems. Therefore, understanding valve dimensions becomes crucial for proper system function.

Key Takeaways

- PVC valves come in many sizes; they are not all the same. Different sizes fit different pipes and system needs.

- Matching the valve size to the pipe size is very important. This stops leaks and helps water flow well.

- You can find the right PVC valve size by checking pipe markings, measuring the pipe, or looking at product details.

Understanding PVC Valve Sizing

Nominal Pipe Size for PVC Valves

Understanding Nominal Pipe Size (NPS) is fundamental when selecting PVC components. NPS represents a standard for pipe and fitting dimensions. It refers to the approximate inner diameter of a pipe. Manufacturers use NPS to ensure consistent sizing across different products. This consistency allows for proper connection and functionality within a plumbing system. Therefore, matching the NPS of a valve to the NPS of the pipe is the first critical step in selection.

Common PVC Valve Dimensions

PVC valves come in a wide array of sizes to accommodate various piping systems. Typical dimensions range from small 1/2-inch valves used in residential applications to larger 4-inch or even 6-inch valves for industrial or main line uses. The connection type also influences the overall dimensions and how the valve integrates into the system. Common connection types include slip (solvent weld) and threaded ends.

| Valve Type | Connection Type | Typical Sizes |

|---|---|---|

| Ball Valve | Slip, Threaded | 1/2″ – 4″ |

| Union Ball Valve | Slip, Threaded | 1/2″ – 4″ |

| Check Valve | Slip, Threaded | 1/2″ – 4″ |

| Swing Check Valve | Slip, Threaded | 1/2″ – 4″ |

| Spring Check Valve | Slip, Threaded | 1/2″ – 4″ |

This table illustrates the common types of PVC valves and their typical size ranges. Each type serves a specific function within a piping network.

Inner and Outer Diameter Differences for PVC Valves

Pipes possess both an inner diameter (ID) and an outer diameter (OD). The outer diameter of PVC pipe remains consistent for a given nominal size, regardless of its schedule. For example, a 1-inch PVC pipe always has an outer diameter of 1.315 inches. This consistency is crucial because fittings, including PVC valves, are designed to match the pipe’s OD.

However, the inner diameter varies based on the pipe’s wall thickness, known as its schedule. Schedule 80 PVC pipe has thicker walls than Schedule 40 pipe. This means Schedule 80 pipe has a slightly smaller inner diameter for the same nominal size.

Consider a 1-inch pipe:

| Pipe Type | Nominal Pipe Size (in) | Outer Diameter (in) | Average Inner Diameter (in) |

|---|---|---|---|

| Schedule 40 | 1″ | 1.315 | 1.029 |

| Schedule 80 | 1″ | 1.315 | 0.936 |

For a 1-inch pipe, the outer diameter measures 1.26 inches. The inner diameter, however, changes with the schedule. Despite these internal differences, a 1-inch fitting will fit a 1-inch pipe, whether it is Schedule 40 or Schedule 80. Fittings are engineered to accommodate the consistent outside diameter of the pipe, not its varying inner diameter. This design principle simplifies the selection process for PVC valves and other fittings.

Factors for Selecting PVC Valves

Pipe Diameter Compatibility for PVC Valves

Proper selection of PVC valves begins with matching the pipe diameter. The valve’s nominal pipe size (NPS) must correspond directly to the pipe’s NPS. This ensures a secure and leak-free connection. Manufacturers design fittings, including PVC valves, to fit the consistent outer diameter (OD) of the pipe. Therefore, a 1-inch valve connects perfectly to a 1-inch pipe, regardless of whether it is Schedule 40 or Schedule 80. This compatibility prevents installation issues and maintains system integrity.

Flow Rate Requirements for PVC Valves

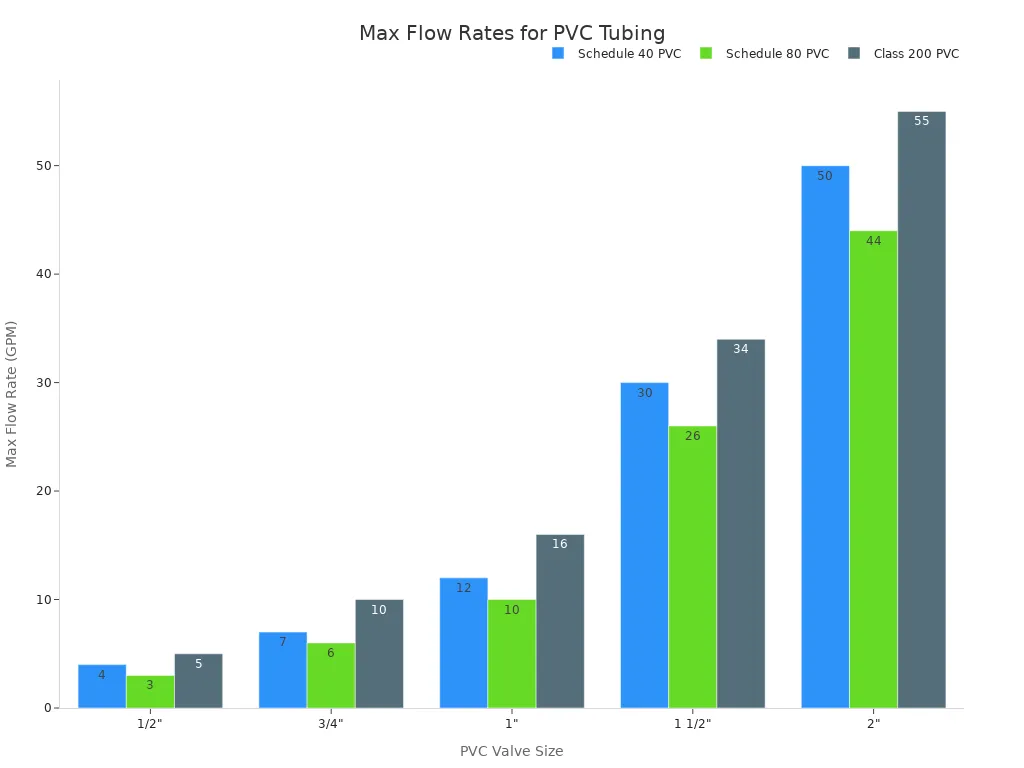

System performance heavily relies on appropriate valve sizing for flow rate. The bore size of a PVC ball valve directly influences the system’s flow rate. It determines the cross-sectional area available for fluid passage. A larger bore reduces resistance, allowing more fluid to pass per minute. A smaller bore restricts this area. This increases fluid velocity and friction. It significantly reduces the total flow rate and increases pressure drop. For instance, a 2-inch bore has an area of approximately 3.14 square inches. A 4-inch bore has an area of approximately 12.56 square inches. Valve sizing depends on the water volume required for a specific zone, not solely on the mainline or lateral line pipe size.

| Tubing Type and Size | Max Flow Rate (GPM) |

|---|---|

| Schedule 40 PVC | |

| 1/2″ | 4 |

| 3/4″ | 7 |

| 1″ | 12 |

| 1 1/2″ | 30 |

| 2″ | 50 |

| Schedule 80 PVC | |

| 1/2″ | 3 |

| 3/4″ | 6 |

| 1″ | 10 |

| 1 1/2″ | 26 |

| 2″ | 44 |

| Class 200 PVC | |

| 1/2″ | 5 |

| 3/4″ | 10 |

| 1″ | 16 |

| 1 1/2″ | 34 |

| 2″ | 55 |

Manufacturers provide pressure loss charts to guide valve selection based on flow rate and valve size. An oversized valve might result in very low pressure loss. This indicates it is too large for the zone’s flow demands. Conversely, a valve causing excessive pressure loss might need upsizing.

Application Specifics for PVC Valves

Different applications demand specific PVC valve sizes. For example, swimming pool plumbing requires particular dimensions for optimal circulation and filtration. Common sizes for pool systems include 3/4-inch PVC ball valves for robust performance in medium-flow requirements. One-inch PVC ball valves are efficient for irrigation systems and pool plumbing. Larger 1 1/2-inch PVC ball valves offer excellent flow characteristics, often with a full-port design to maximize capacity. Two-inch PVC ball valves represent the larger end of standard mid-range options. They are frequently used in substantial pool and spa systems for high throughput. For even larger systems, 2 1/2-inch PVC ball valves bridge the gap to large-scale applications. They provide a significant increase in flow capacity for commercial irrigation main lines and larger swimming pool filtration systems.

Identifying the Correct PVC Valve Size

Accurately identifying the correct PVC valve size is crucial for any plumbing project. Mismatched components lead to leaks, inefficient flow, and potential system failure. Several methods help determine the precise dimensions needed for a successful installation.

Checking Existing PVC Pipe Markings

The easiest way to determine pipe size involves checking the markings directly on the PVC pipe. Manufacturers typically print essential information on the pipe’s outside surface. This information includes the PVC size, often in fractional or decimal format. You might see units like ‘inch’, ‘in.’, or the double quote symbol (“). The markings also indicate the PVC schedule, such as ‘Schedule’, ‘SCH’, or ‘Sched.’, followed by a number. Common schedule numbers are 40 (the most common), 80, or 120 (the least common). These markings provide a direct reference for selecting compatible PVC valves.

Measuring PVC Pipe Diameter

When pipe markings are absent or unreadable, measuring the pipe’s diameter becomes necessary. This method ensures accuracy in valve selection. To measure the outer diameter (OD) of a PVC pipe, first locate the end of the pipe. Then, identify the widest point across the opening. Measure from one outside edge to the opposite outside edge. This measurement represents the outside diameter (OD). For precise measurements, professionals often use a tape measure or a caliper. A caliper offers greater accuracy for smaller pipe sizes. Remember, fittings, including PVC valves, are designed to match the pipe’s consistent outer diameter.

Consulting PVC Valve Product Specifications

After determining the pipe size, consult the product specifications for the PVC valves you intend to use. Manufacturers provide detailed datasheets for their products. These specifications list crucial information, including available pipe sizes. For example, some proportional control ball valves come in sizes from 1/2″ to 2″, with specific mention of 1″ pipe size. The datasheets also detail pressure ratings, such as 250 PSI at 70°F non-shock for 1/4″ – 2″ ball valves, or 235 PSI at 70°F non-shock for 2-1/2” – 4” valves. For flanged ball valves, a rating of 150 PSI at 70°F non-shock applies to all sizes of ANSI 150 lb. The specifications also indicate available sizes, such as 1/2″/DN15 to 4″/DN100, with various end connections like IPS, DIN/EN, or JIS socket, threaded, and flanged. Reviewing these specifications ensures compatibility and optimal performance for your system.

PVC valves are not universally sized; they come in diverse dimensions to suit specific pipe diameters and system needs. Accurate identification and selection of PVC valve size are critical for system functionality and integrity. Mismatched PVC valves can lead to leaks, inefficient flow, and system failure. Undersized valves create bottlenecks, leading to frustrating issues and often requiring expensive replacements to rectify the problem.

FAQ

Are all PVC valves universally sized?

No, PVC valves come in many sizes. Manufacturers design them for different pipe diameters and system needs.

Why is matching PVC valve size to pipe size important?

Matching valve size ensures a secure, leak-free connection. It also maintains proper flow and system integrity.

What happens if one uses the wrong PVC valve size?

Mismatched PVC valves cause leaks, inefficient flow, and system failure. Undersized valves create bottlenecks.